Tillage harrow device for automatic mung bean planter

A planting machine and mung bean technology are applied in the directions of planting methods, fertilizers and planting equipment, applications, etc., which can solve the problems of low artificial planting efficiency of mung bean, and achieve the effect of improving planting efficiency and good fertility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment.

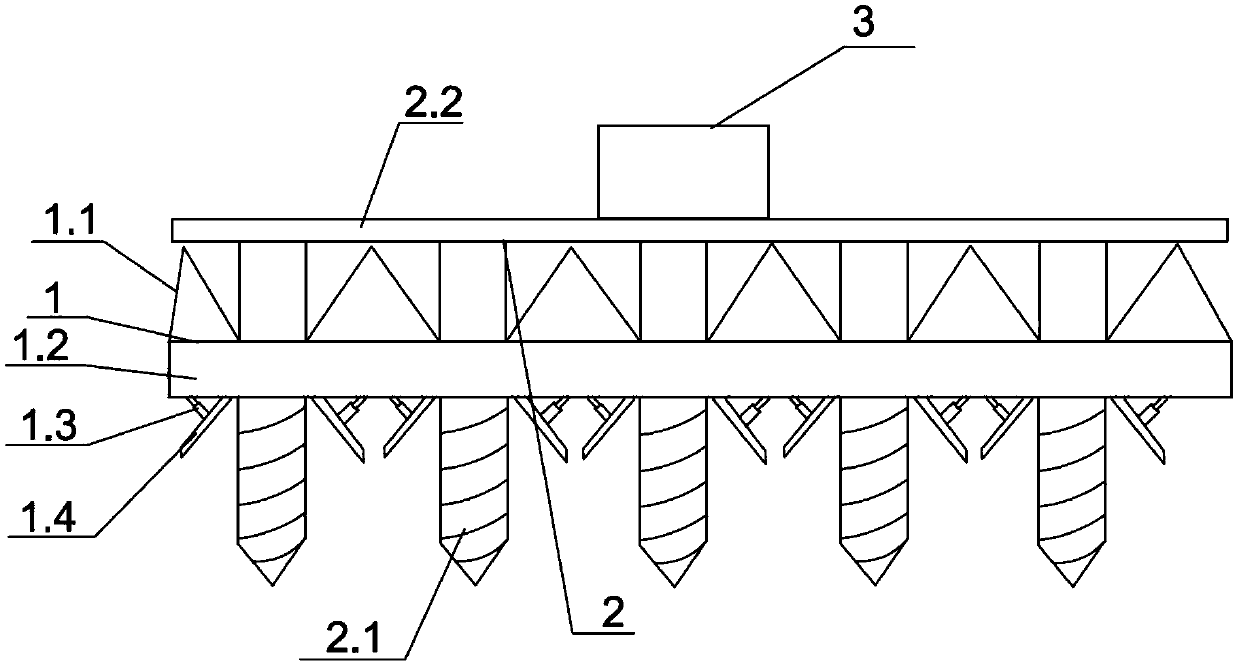

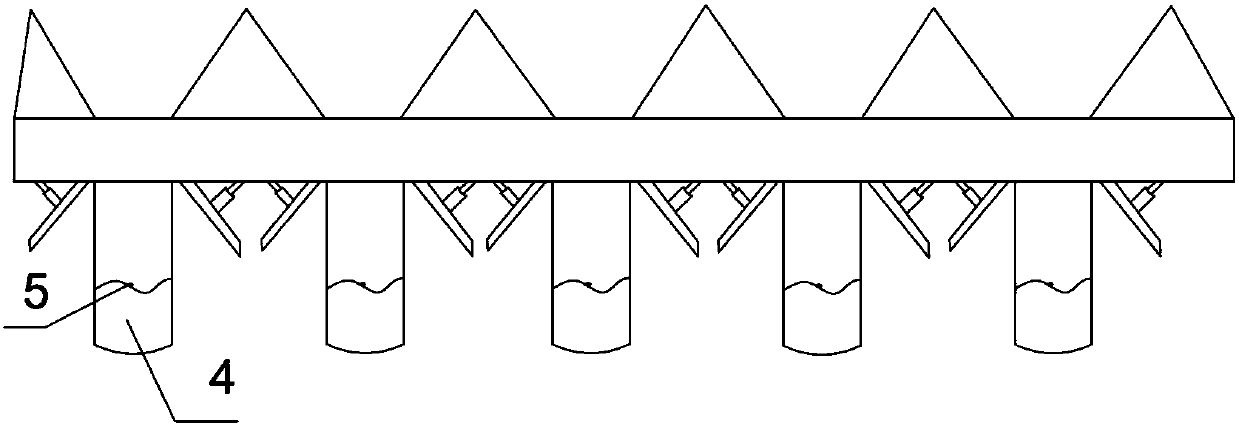

[0019] like Figure 1-2 As shown, a cultivating rake device of an automatic mung bean planter, a converging device 1, a vortex forming device 2 and a power box 3, the vortex forming device 2 is sleeved on the converging device 1, and the power box 3 is arranged on the vortex forming device 2 on. The power box 3 is a reduction box or an electric motor, etc., wherein the power box 3 can be some existing reduction boxes, and there is no fixed limitation in this application.

[0020] The converging device 1 includes a boss 1.1, a leveling layer 1.2, a hydraulic shaft 1.3 and a mud return plate 1.4. The leveling layer 1.2 is provided with several planting holes, and the diameter of the planting holes is 10 cm-20 cm. The bottom of the leveling layer 1.2 is located on the edge of the planting hole and is provided with a return mud plate 1.4, and the back side of the return mud plate 1.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com