Positioning anti-sinking device for processing automobile brake drum and processing method thereof

An automobile braking and anti-sinking technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of products that cannot meet the requirements of high efficiency and quality, increased cylindricity and circular runout of brake drums, Inaccurate processing reference line and other problems, to achieve the effect of improving operation convenience, uniform force, and improving product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

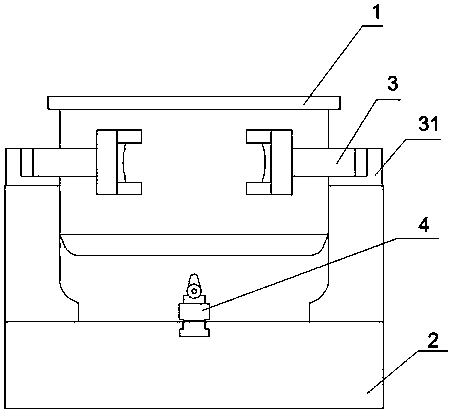

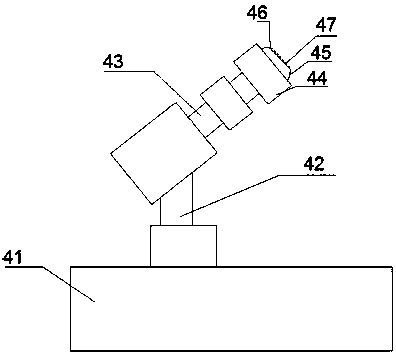

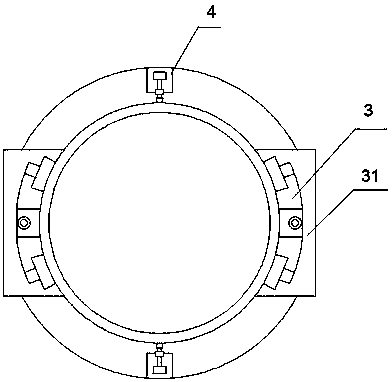

[0036] as attached Figures 1 to 3 As shown, the positioning and anti-sinking device for processing automobile brake drums in this embodiment is installed on the workbench 2 of the ZL2-550 vertical lathe, and two groups of claws are arranged symmetrically on the workbench 2 3. It also includes two sets of anti-sinking mechanisms 4 that are symmetrically arranged and staggered with the positions of the two sets of claws. The anti-sinking mechanism includes a base 41, a height adjustment part 42, a length adjustment part 43 and a support part 44; the support The portion 44 is arranged at one end of the length adjusting portion 43 close to the center of the workbench 2, the opposite end of the length adjusting portion 43 is connected to the upper end of the height adjusting portion 42, and the lower end of the height adjusting portion 42 is connected to the The base 41; the length adjustment part 43 is set from one end connected to the height adjustment part 42 to one end connect...

Embodiment 2

[0040] as attached Figure 4As shown, different from Embodiment 1, the present Embodiment 2 is provided with three sets of identical anti-sinking mechanisms 4, which are arranged at an angle of 120 degrees between two pairs of spaces other than the two sets of claws 3 on the workbench 2; Three sets of anti-sinking mechanisms 4 are used obliquely on the side wall of the bottom of the brake drum 1, and the force can be adjusted to point to a position closer to the body center of the product. The triangular force is more stable and uniform, and can be further improved. Reduce the error generated during processing and avoid the possibility of local sinking deviation of the brake drum 1;

Embodiment 3

[0042] as attached Figure 5 As shown, on the basis of Embodiment 2, the included angle d between the inclined working surface 46 and the support portion 44 in Embodiment 3 is 10 degrees, and the convex portion of the arc surface is evenly arranged on the inclined working surface 46 , reduce the probability of not fitting with the contact surface, and reduce the error; the length adjustment part 43 is also provided with an inclination angle adjustment mechanism, which can be superimposed by connecting the length adjustment part 43 and the height adjustment part 42 with an existing damping Realized by means of a rotating shaft, the inclination angle of the length adjusting part 43 is controlled between 30 degrees and 80 degrees, which further improves the operation convenience and product adaptability of the anti-sinking mechanism.

[0043] as attached Figure 6 , Table 1, Table 2 and Table 3, ten brake drums 1 were selected at random respectively, processed by lathes without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com