Large-diameter countersink reverse reaming tool for numerical control machining

A large-diameter, countersunk hole technology, used in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of difficult to achieve bolt through-hole ends, inconvenient turning, bulky, etc., to reduce the phenomenon of knife vibration , to ensure the quality of processing, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

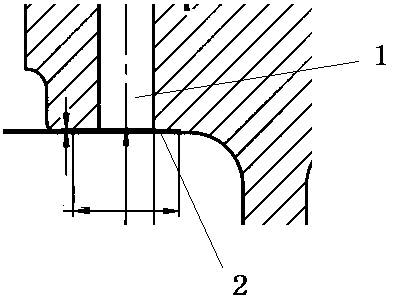

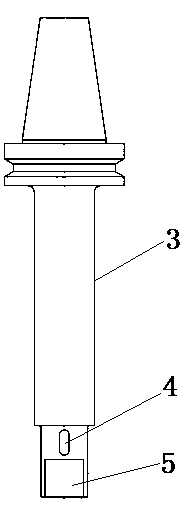

[0026] As shown in the figure, a large-diameter countersinking tool for countersinking in this patent application is characterized in that it includes a tool holder 3, a tool body, a key and a stopper.

[0027] The lower part of the tool bar 3 is provided with a first keyway 4 , and the lower part of the first keyway 4 is provided with a stopper mounting part 5 .

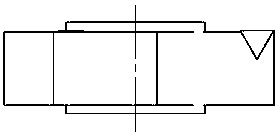

[0028] The cutter body includes a body and three blades.

[0029] The middle part of the body is provided with a mounting hole, and the inner side of the mounting hole is provided with a through second keyway 6; the outer side of the body is provided with three blade installation parts; the outer surfaces of the three blade installation parts are all arc-shaped , coincides with the inner diameter of the counterbore 2 to be processed; the three blade installation parts are respectively the first blade installation part 7 , the second blade installation part 8 and the third blade installation part 9 .

[0030] The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com