Fixed point bracket for screw welding technology

A welding process and screw technology, which is applied in the field of screw welding positioning brackets, can solve the problems of welding point positioning range and insufficient safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

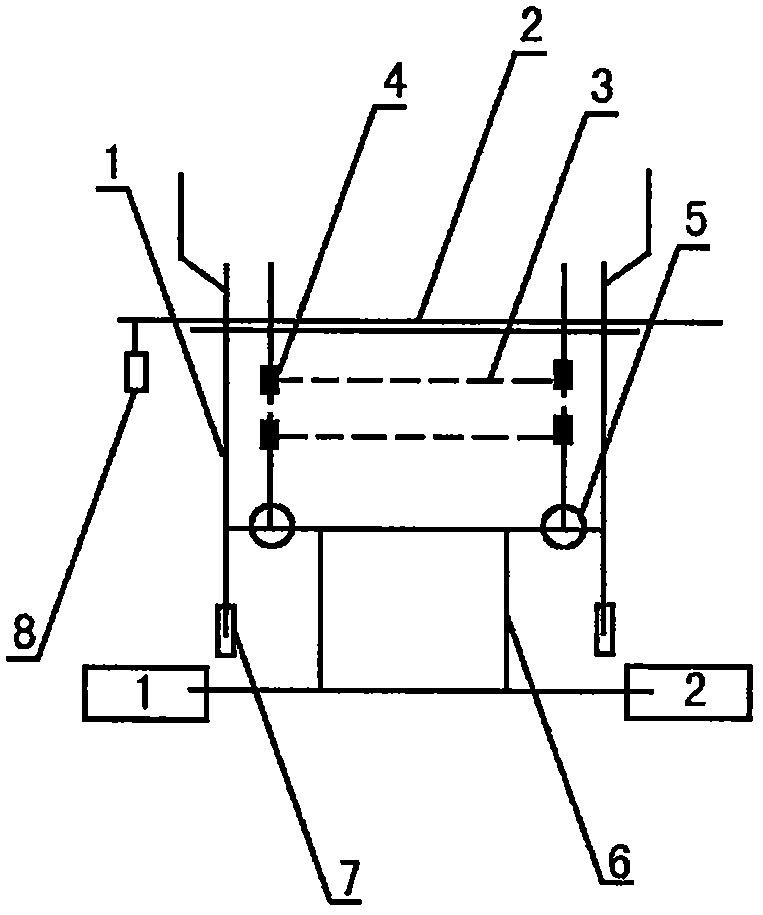

[0012] Embodiment: as shown in the accompanying drawing. The fixed-point bracket used for the screw welding process includes a frame body (1), and the frame body (1) is designed with a symmetrical structure at both ends, including a distance adjusting rod device (2), a longitudinal screw idler frame (3), and a guide module ( 4), the adjustment button (5), the extension bracket (6), and the object sensing device (7) are respectively located on both sides of the support frame, and the frame body (1) is suspended in the middle of the two welding machines during operation, and the corresponding distance is adjusted according to the position of the solder joints Make the screw move to the welding area smoothly.

[0013] The fixed-point bracket used for the screw welding process is equipped with a prompting device (8), and when the sensing device (7) detects that the welding is completed, a corresponding prompting message is sent.

[0014] Fixed-point support for screw welding proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com