Linear guide rail packing device

A linear guide, packaging technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of pollution, product damage, slow packaging, etc., to achieve efficient and flexible operation, speed up packaging, and tight packaging good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

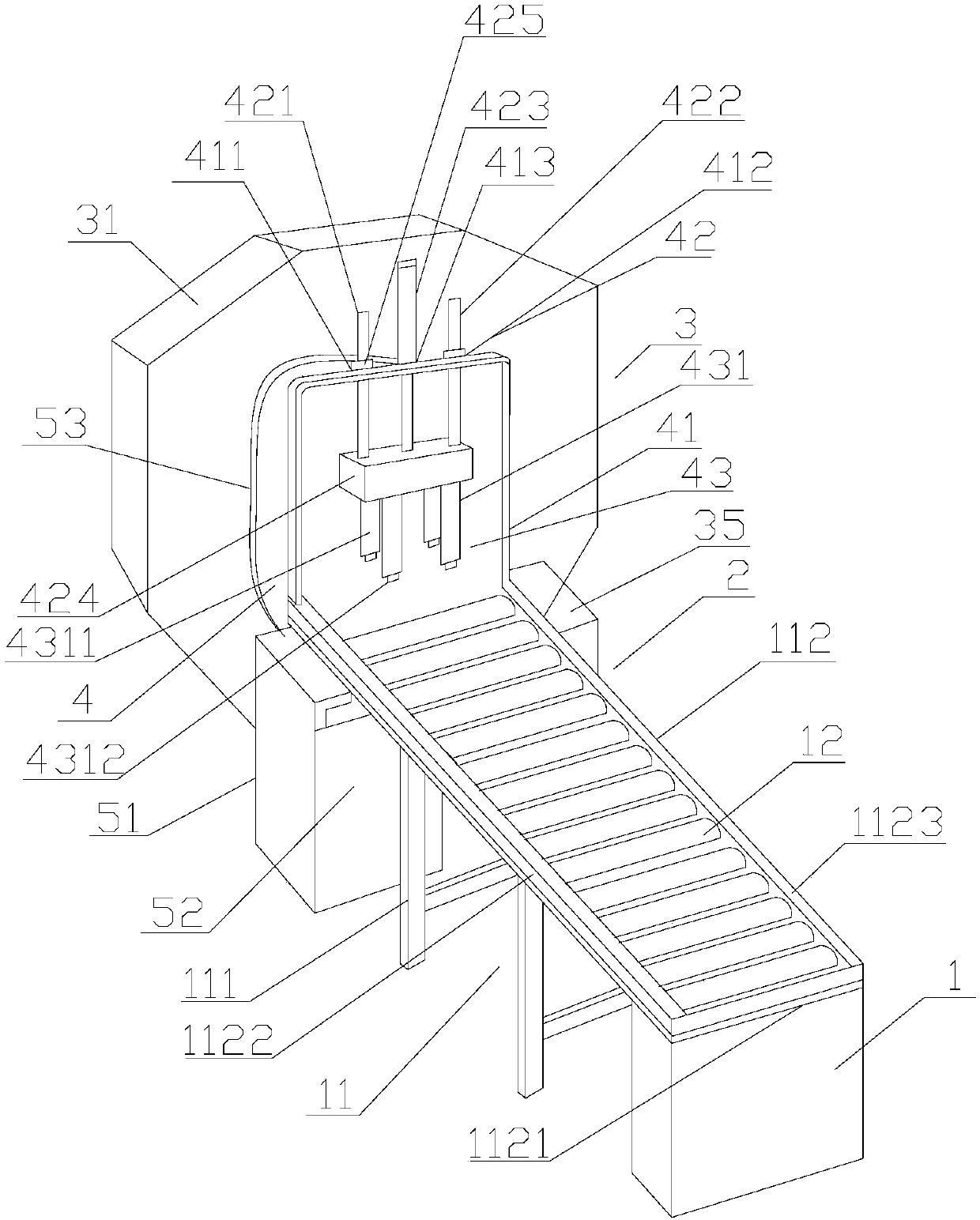

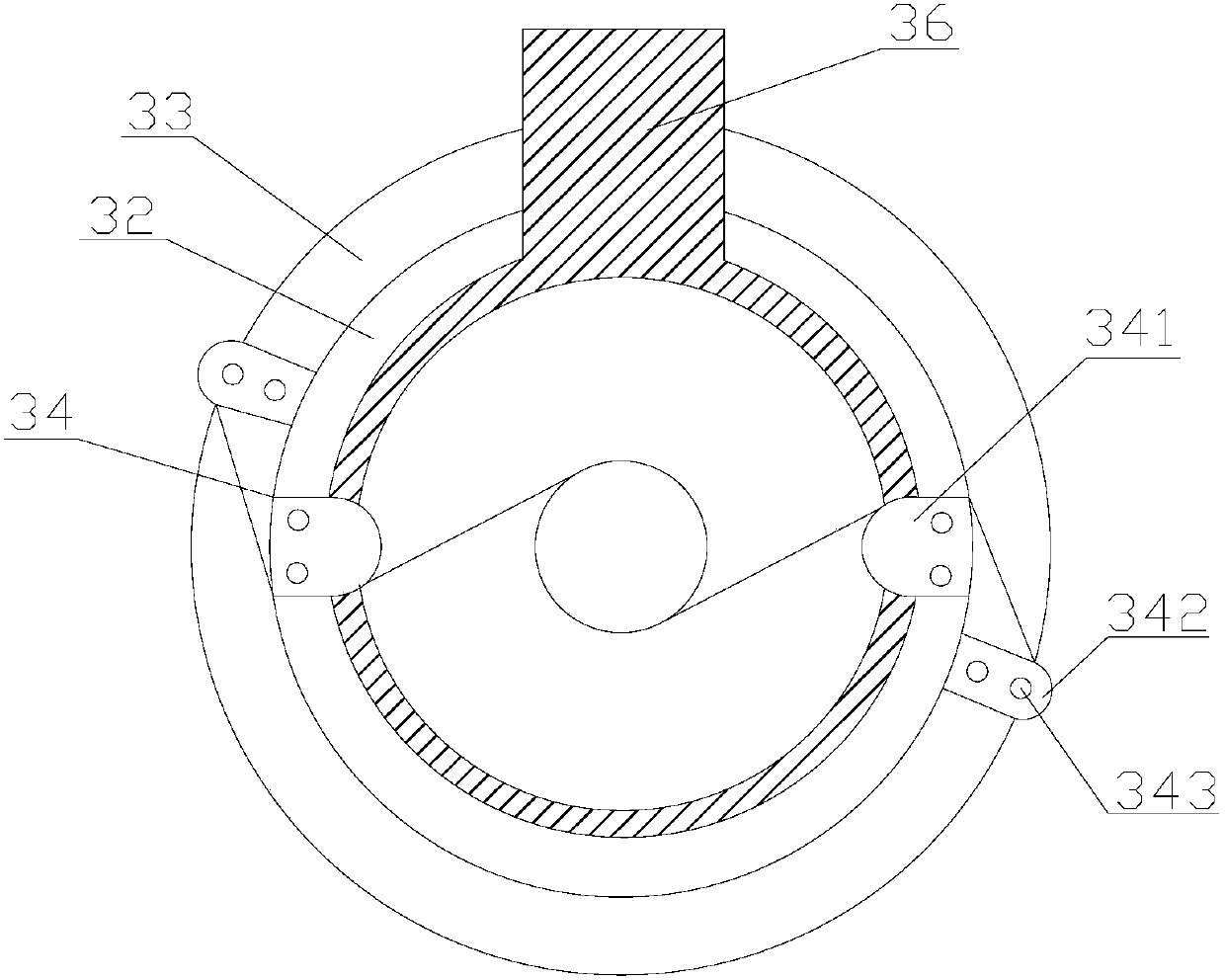

[0017] refer to figure 1 and 2 , a linear guide rail packaging device of the present invention, comprising a frame 1, a conveying mechanism 2, a packaging mechanism 3 and a fixing mechanism 4, the conveying mechanism 2 is horizontally installed on the frame 1, and the outer side of one end of the conveying mechanism 2 is provided There are packing mechanism 3 and fixing mechanism 4, and described conveying mechanism 2 comprises conveying frame 11 and some axle rollers 12, and described axle roller 12 is installed in conveying frame 11 inner side, and described fixing mechanism 4 comprises fixed frame 41, elevating frame 42 and Clamping mechanism 43, the fixed frame 41 is a rectangular frame structure, connected to the inner side of the transport frame 11, the upper end of the fixed frame 41 is provided with a lifting frame 42, and the bottom of the lifting frame 42 is provided with a clamping mechanism 43. The conveying mechanism 2, the packaging mechanism 3 and the fixing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com