Curable composition cured product and light emitting device and manufacturing method for same

A technology for a light-emitting device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as deterioration of light-emitting materials, and achieve less film unevenness, less outgas generation after hardening, and less wetting. Excellent scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

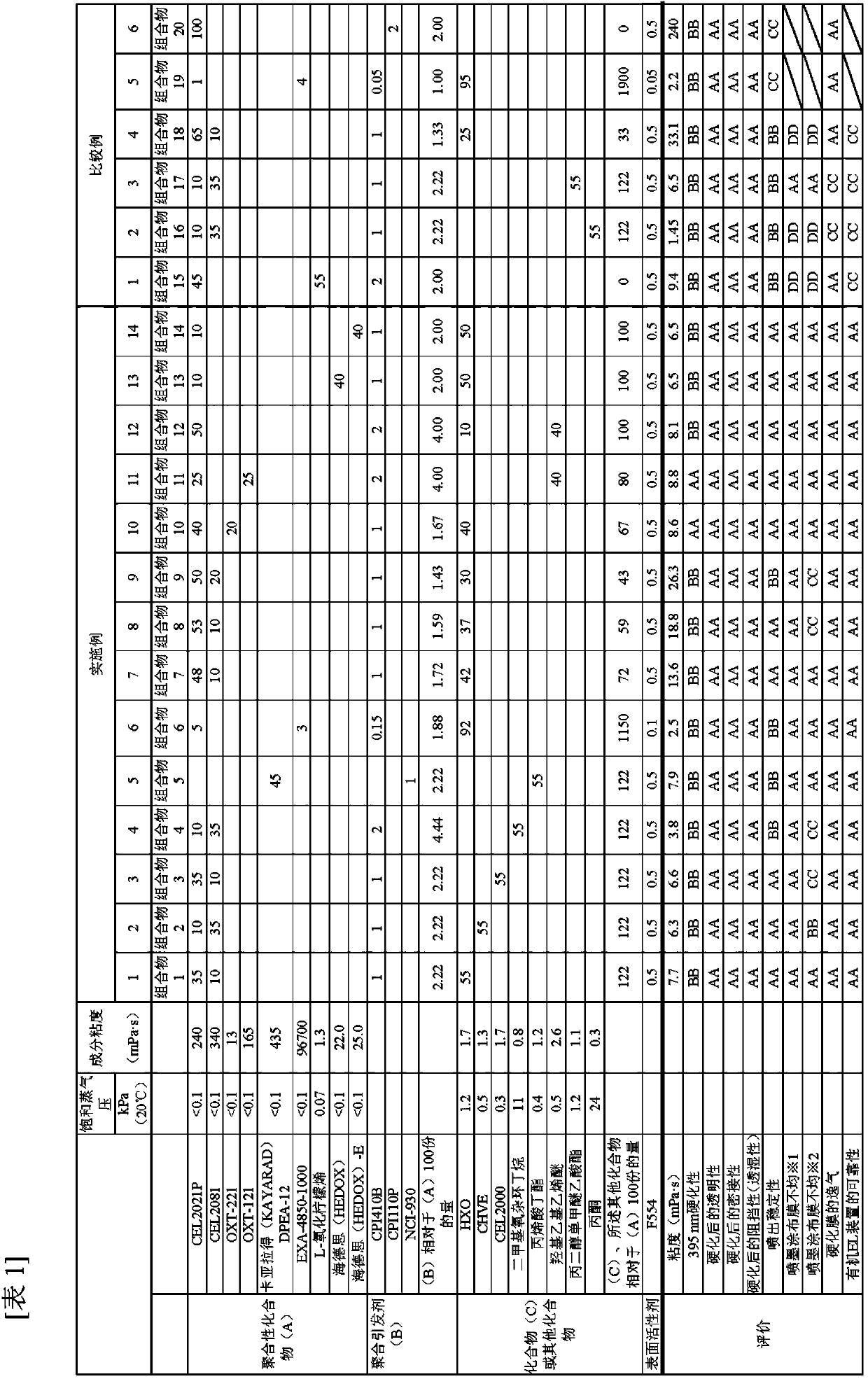

[0132] In Example 1, 35 parts of CEL2021P, 10 parts of CEL2081, 1 part of CPI410B, 55 parts of HXO, and 0.5 part of F554 were mixed under atmospheric conditions to prepare curable composition 1. Except having used each component of the kind and compounding quantity shown in Table 1, it carried out similarly to Example 1, and prepared curable composition 2 - curable composition 20.

[0133] "evaluate"

[0134]

[0135] A plurality of array substrates were prepared. The array substrates had: a glass substrate ("OA-10" manufactured by NEC Glass Co., Ltd.) on which ITO transparent electrodes were formed in an array; and only a part of the ITO transparent electrodes. A planarization layer with a film thickness of 3 μm for exposed contact holes.

[0136] An Al film with a film thickness of 100 nm was formed on the planarization layer by a direct current (DC) sputtering method using an Al target. An ITO film with a film thickness of 20 nm was formed on the Al film by the DC magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com