Prefabricated RC column inflection-point aligned connection method

A technology of prefabricated assembly and connection method, applied in the direction of building, building structure, etc., can solve the problem of easy damage of nodes, and achieve the effect of fast construction speed, strong economy and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

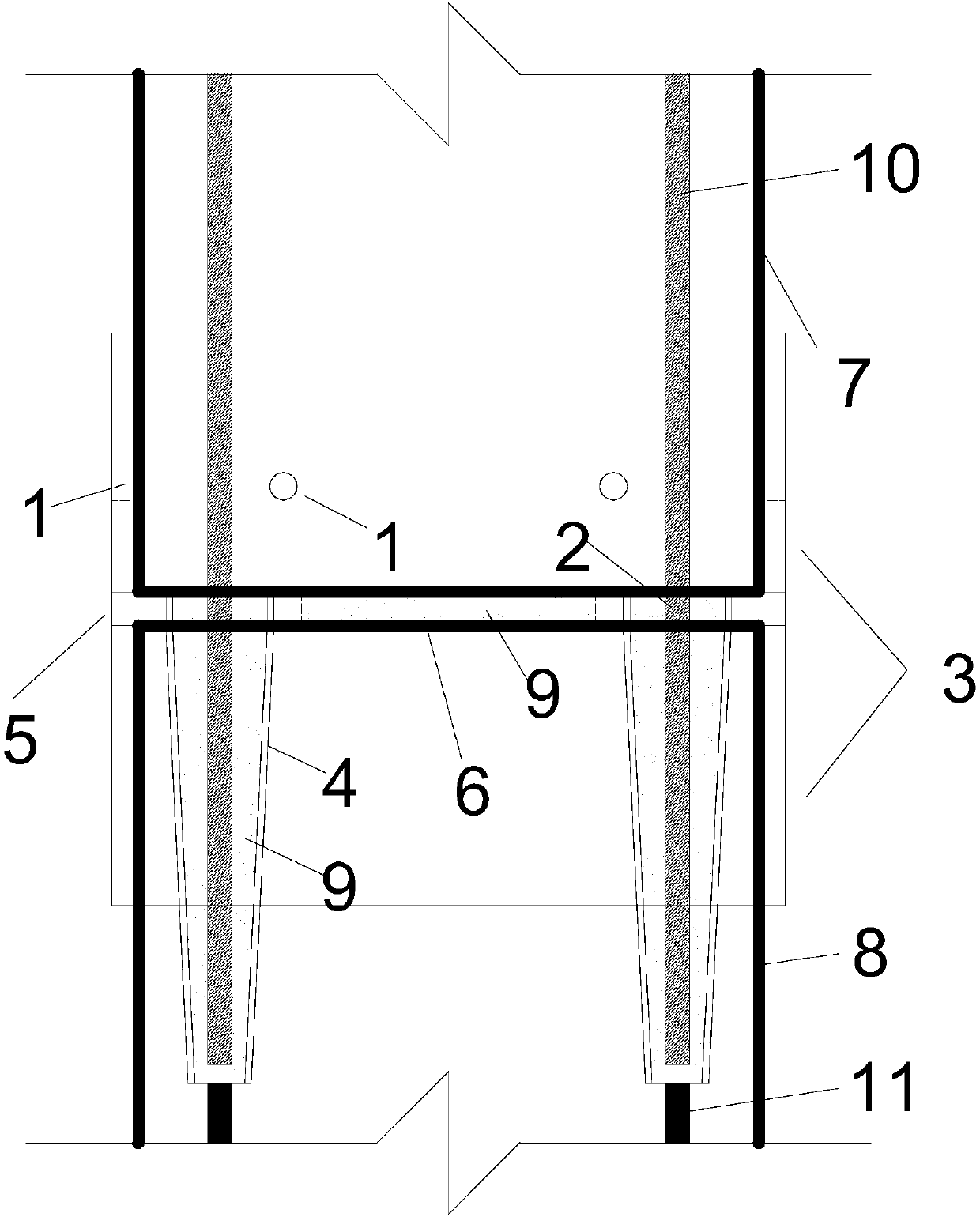

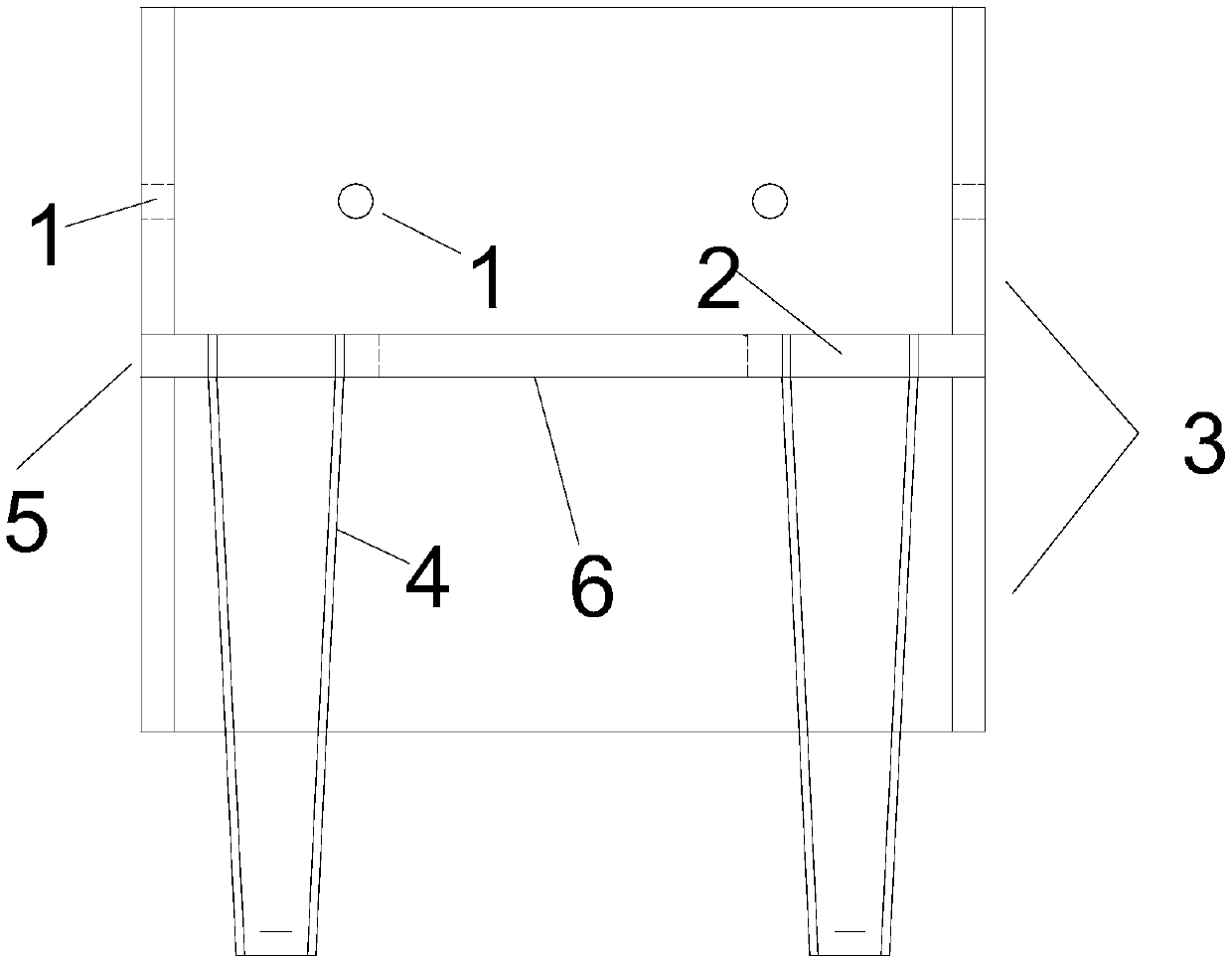

[0025] Such as Figure 1-2 , a prefabricated assembled RC column inflection point alignment connection method of the present invention includes a prefabricated assembled RC column inflection point alignment connection device, and the prefabricated assembled RC column inflection point alignment connection device includes an outer shell 3, The outer sleeve 4 and the middle connecting plate 5; the outer sleeve 3 is surrounded to form a square cross-sectional structure, the middle part of the outer sleeve 3 is provided with a horizontally arranged intermediate connecting plate 5, and the bottom surface of the intermediate connecting plate 5 is provided with an inverted tapered jacket A grouting hole 2 is provided at the connection between the sleeve 4 and the outer sleeve 4 and the upper opening of the intermediate connecting plate 5 . The middle part of the intermediate connecting plate 5 is also provided with an intermediate connecting plate through hole 6 . The through hole 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com