Truss load-bearing platform structure of three-pipe telescopic chimney

A load-bearing platform and chimney technology, which is applied in the field of chimneys of thermal power plants, can solve the problems of large area occupation, unfavorable costs, and poor engineering economy, and achieve the effects of reducing the amount of reinforced concrete, improving mechanical performance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

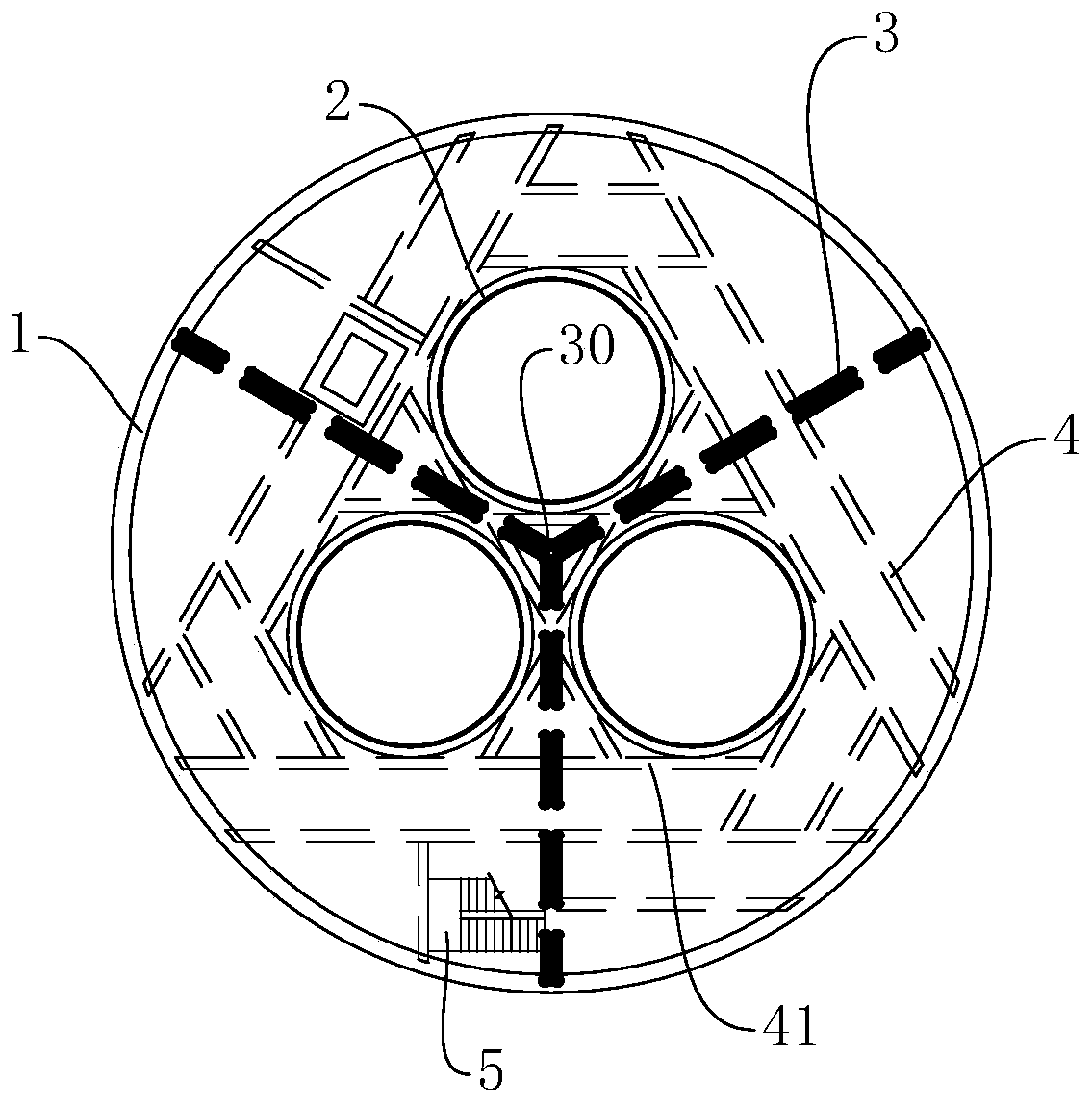

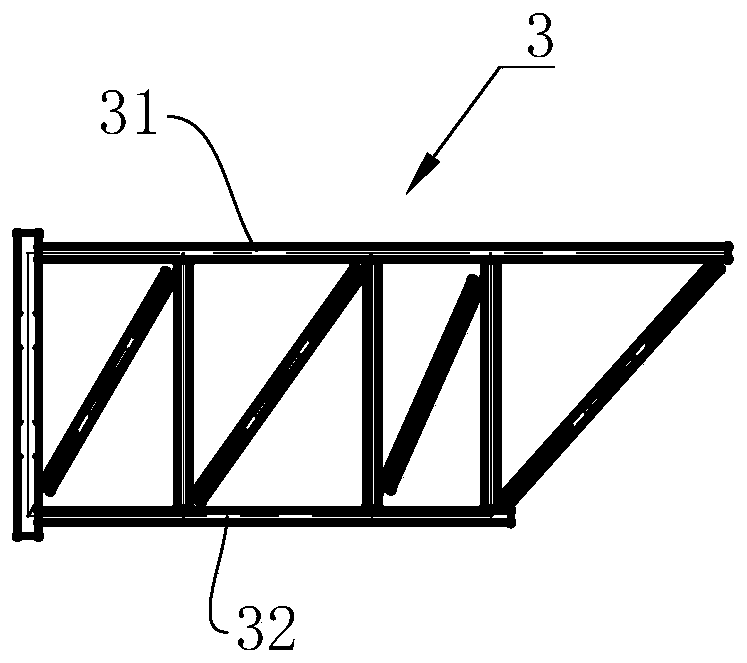

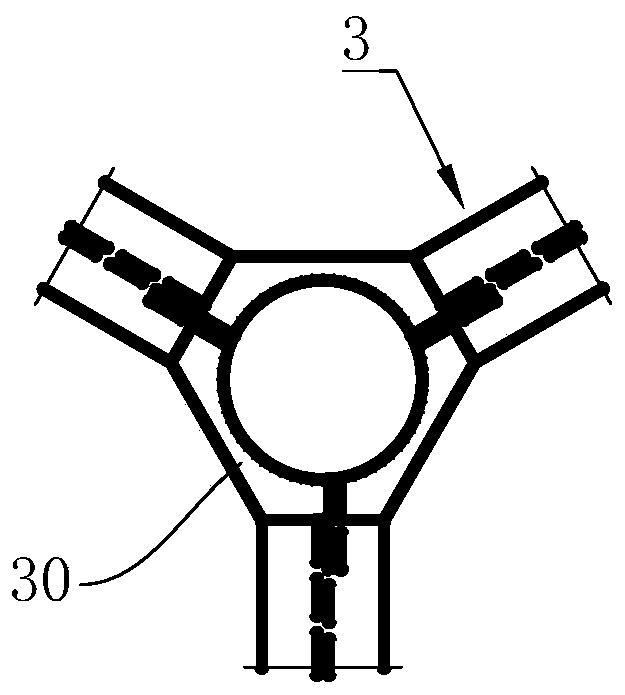

[0017] The truss load-bearing platform structure of the three-pipe telescopic chimney includes a chimney outer cylinder 1, and three chimney inner cylinders 2 are arranged inside the chimney outer cylinder 1, and the cross-sectional circle centers of the three chimney inner cylinders 2 are along the corner points of an equilateral triangle. The layout also includes three main girders 3, the main girders 3 include an upper chord 31 and a lower chord 32, and a plurality of web members are connected between the upper chord 31 and the lower chord 32, and form a truss structure; the main girder One end of 3 is connected to the inner wall of the chimney outer cylinder 1, the other end of the main beam 3 is located at the center of the section of the chimney outer cylinder 1, and is connected with the ends of the other two main beams 3, and the three main beams 3 connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com