Intake system component of internal combustion engine and method for manufacturing intake system component of internal combustion engine

A technology for air intake system and internal combustion engine, applied in charging system, engine components, combined air filter and muffler, etc., can solve problems such as low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

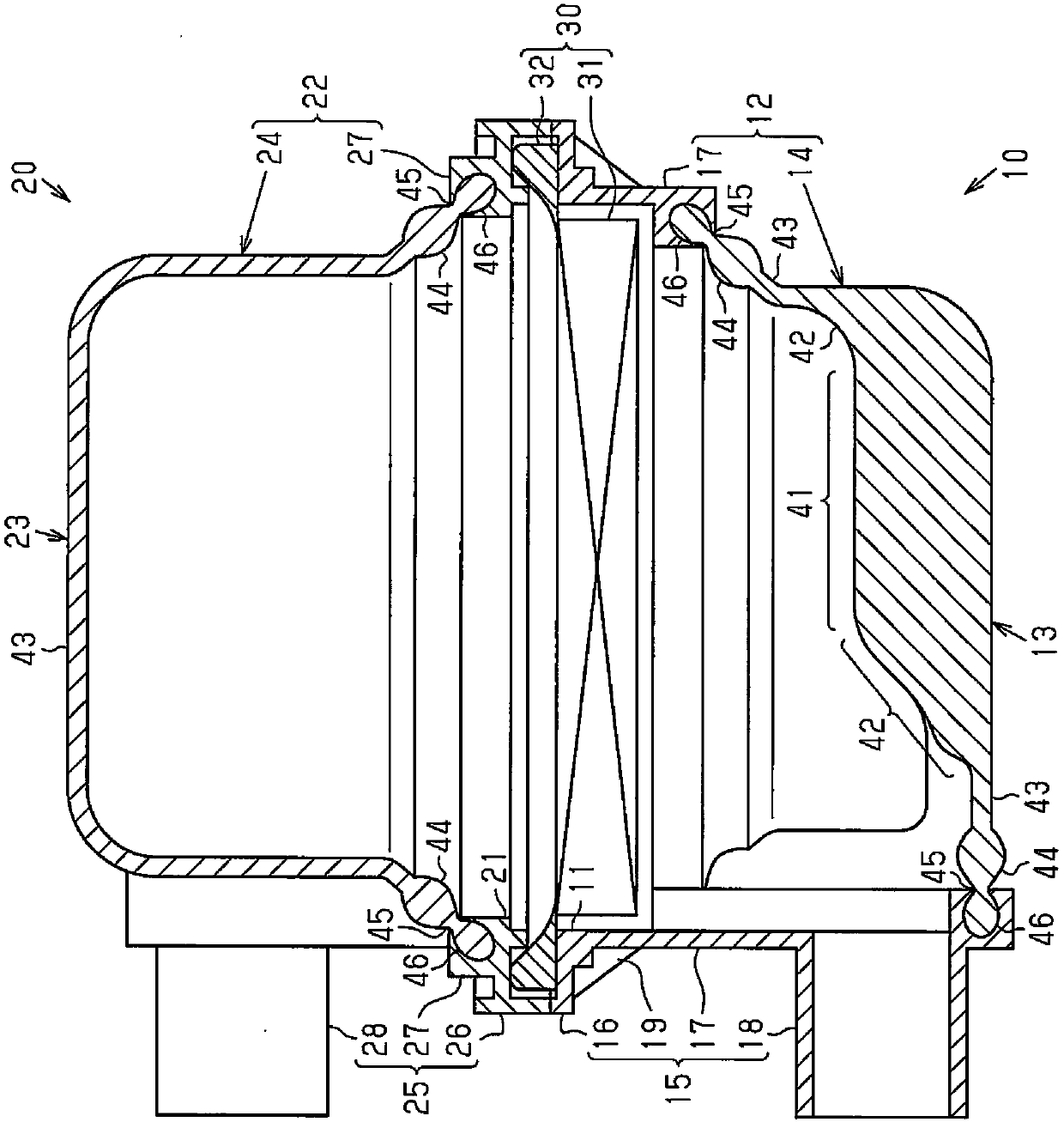

[0016] will now refer to Figure 1 to Figure 4 One embodiment will be described.

[0017] refer to figure 1 , an air filter is arranged in the intake passage of the internal combustion engine of the vehicle. The air filter comprises a first housing 10 with an inlet 18 , a second housing 20 with an outlet 28 and a filter element 30 . The filter element 30 is located between the upper opening 11 of the first housing 10 and the lower opening 21 of the second housing 20 opposite to the upper opening 11 .

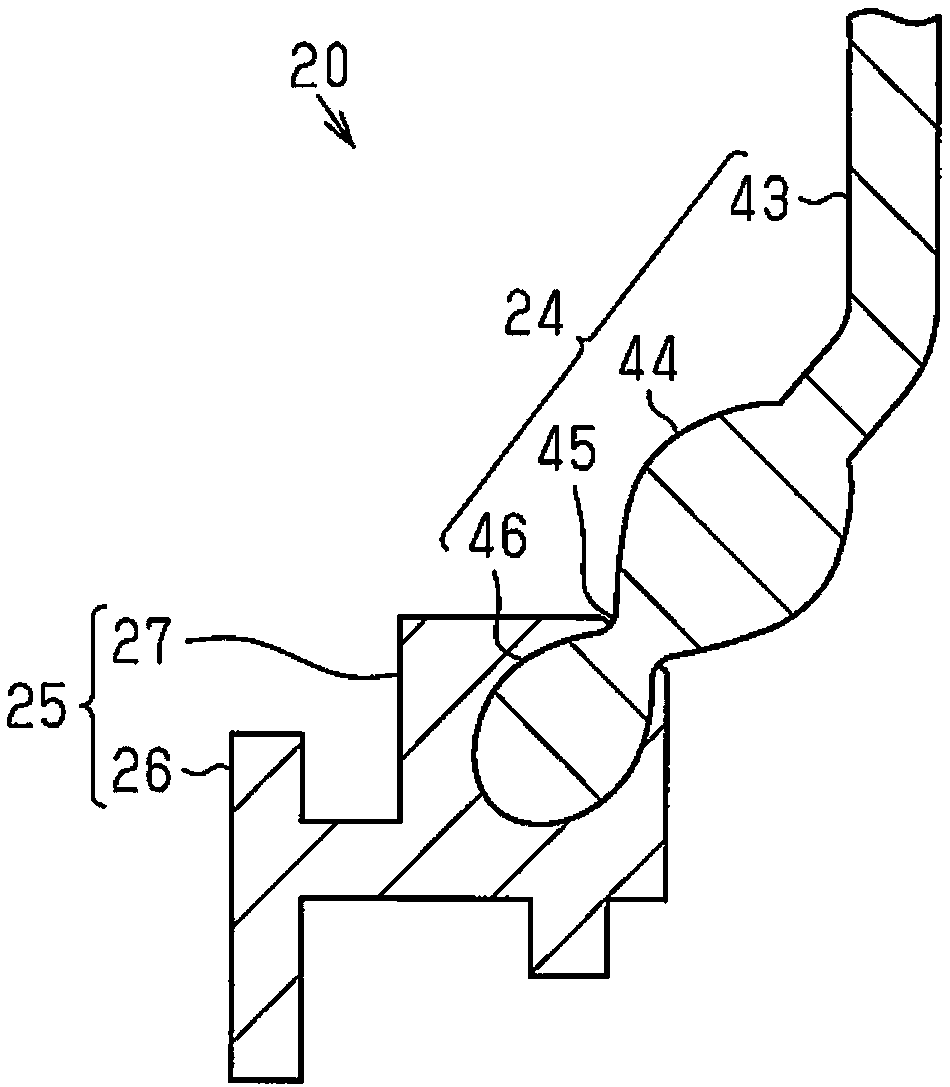

[0018] The first housing 10 includes a bottom wall 13 and a peripheral wall 12 surrounding the upper opening 11 . An annular flange 16 protrudes from the periphery of the upper opening 11 toward the outside. The inlet 18 is tubular and protrudes from the outer surface of the peripheral wall 12 .

[0019] The second housing 20 includes a top wall 23 and a peripheral wall 22 surrounding the lower opening 21 . An annular flange 26 protrudes from the periphery of the lower ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com