High-precision balancing flower meter

A flow-balanced, high-precision technology that is used in volume measurement, liquid/fluid solids measurement, volume/mass flow due to mechanical effects, etc. It can solve the problem of limiting flow measurement range, high installation conditions, and narrow measurement range. and other problems to achieve the effect of reducing the loss of kinetic energy, ensuring accuracy, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

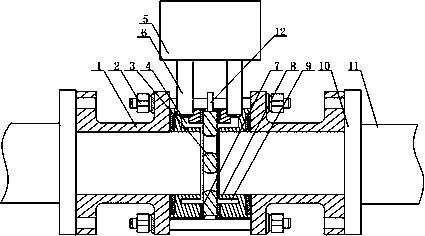

[0020] Such as figure 1 As shown, this embodiment includes a connecting pipe 1 with a flange, a straight pipe section 11, a sensor, two packing rings 8 and two pressure-taking pipes 6, and the adjacent ends of the two connecting pipes 1 with flanges The ends are connected together by bolts 2, and the other end of the connecting pipe 1 is connected with the straight pipe section 11 through the flange 10. On the opposite end faces of the two connecting pipes 1, packing rings 8 are arranged respectively, and the orifice plate body 3 is arranged between two pack-off rings 8. There are multiple nozzles on the orifice plate body 3, and an air passage 4 communicating with the connecting pipe 1 is opened on one side of the pack-off ring 8, and one end of the pressure-taking tube 6 is It communicates with the air passage 4, and the other end of the pressure-taking pipe 6 communicates with the sensor. On the inner wall of the other side of the packing ring 8, there is a buffer groove 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com