Side compression hall sensor for tension detection

A hall sensor and tension detection technology, which is applied in the direction of tension measurement, instruments, and the measurement of the change force of the material magnetic properties caused by the applied stress, which can solve the problem of high installation angle requirements, easy output deviation, and calibration process. Complicated problems, to achieve the effect of high sensitivity, fast response, and reduce the installation angle requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

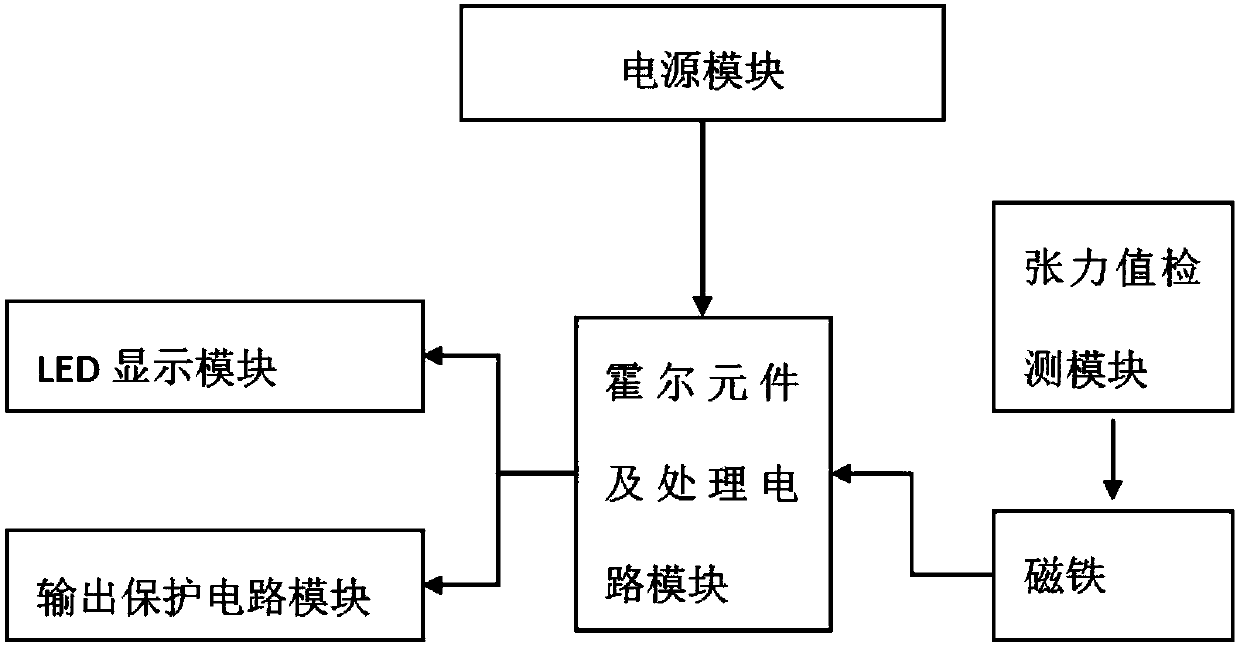

[0025] see figure 1 , a side pressure Hall sensor for tension detection according to the present invention mainly includes a Hall element and a processing circuit module, a tension value detection module, a power supply module, a magnet, an output protection circuit module and an LED display module;

[0026] Wherein, the tension value detection module is installed on the side of the yarn reel to be detected, which is used to detect the tension value of the yarn and convert it into a corresponding displacement; a limited position measure is designed to prevent sudden Excessive tension causes irreversible damage to the detection module.

[0027] The magnet is used to change the distance from the Hall element and the processing circuit module accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com