Electric power circuit splicing sleeve correction tool

A technology for power lines and splicing pipes, which is applied to equipment for connecting/terminating cables, etc., can solve problems such as labor-intensive and time-consuming safety risks, easily damaged crimping pipes, restricting operation efficiency, etc., to improve construction quality and service life, and easy to operate. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

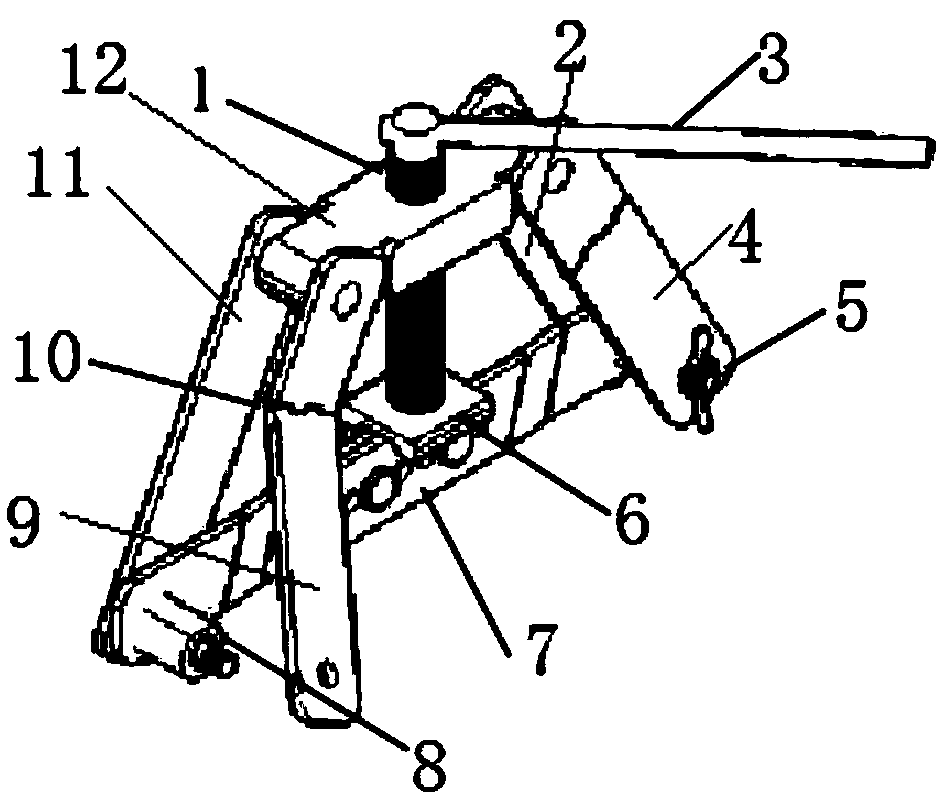

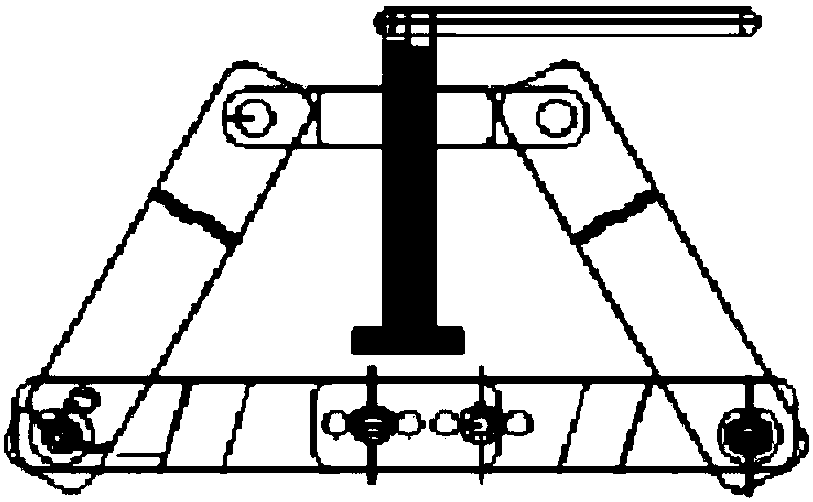

[0022] A calibration tool for connecting tubes of power lines, which includes screw rod 1, right rear connecting arm 2, crank handle 3, right front connecting arm 4, butterfly nut 5, dynamic pressure seat 6, lower connecting arm 7, constant pressure seat 8. The left front connecting arm 9, the side connecting arm hinge 10, the left rear side connecting arm 11 and the mounting base 12, the screw rod 1 is installed in the threaded hole on the mounting base 12, the crank handle 3 and the screw rod 1 is connected with an adjustable ratchet mechanism with a ratchet, the upper ends of the right rear connecting arm 2 and the right front connecting arm 4 are mounted on the right end of the mounting base 12 through a hinge, and the left front connecting arm 9 and the left rear connecting arm 11 is installed on the left end of the mounting seat 12 through a hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com