Transmission shaft body structure

A transmission shaft and shaft body technology, applied in the field of transmission, can solve the problems of unreasonable structural design of the transmission shaft body, inability to perform variable frequency speed regulation, unsuitable for industrialized large-scale production, etc., and achieves convenient implementation, stable installation place, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

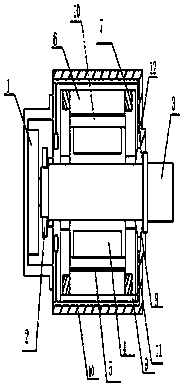

Image

Examples

Embodiment Construction

[0008] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0009] Such as figure 1 As shown, a transmission shaft structure, which includes a transmission housing 11 and a motor 1 located in the transmission housing 11, a shaft 3 is provided on one side of the motor 1, and the motor 1 is a variable speed adjustable motor. One end of the shaft body 3 is provided with a speed sensor 2, and the inner side of the transmission shell 11 is provided with a transmission inner shell 9, and one side of the transmission inner shell 9 is provided with a first stator core 6, and the first stator core 6 is provided with a stator winding 7, one side of the first stator core 6 is provided with a permanent magnet 5, and the other side of the permanent magnet 5 is provided with a second stator core 10, and the second stator core 10 A limit block 4 is provided on one side, a bearing 8 is provided on the shaft body 3 , and at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com