Belt conveying line

A technology of belt conveying and belt, which is applied in the field of automatic conveying devices, can solve the problems of inconvenient passage for operators, unfavorable and flexible passage, etc., and achieve the effects of continuous automatic production, flexible folding and convenient passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

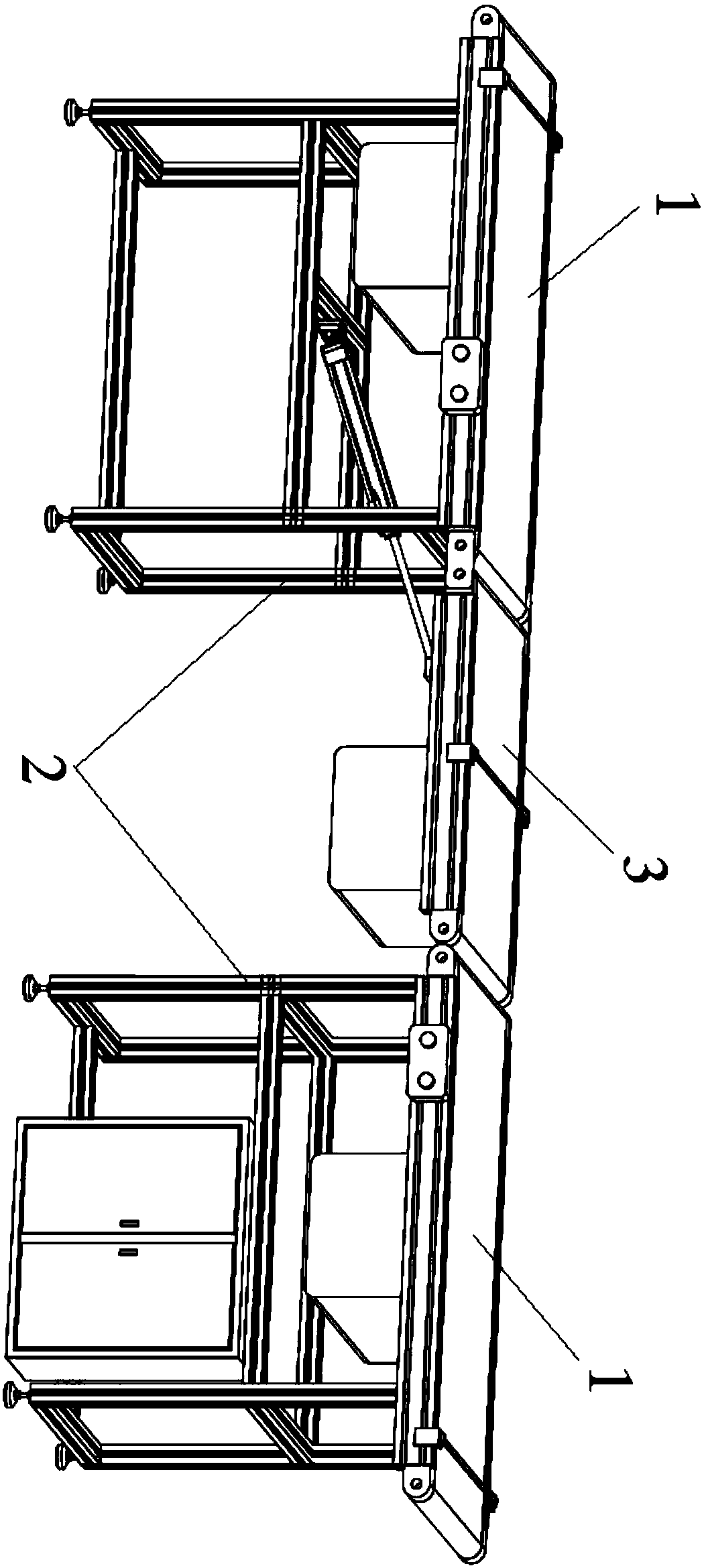

[0020] Such as figure 1 As shown, a belt conveying line is disclosed in this embodiment, which includes a plurality of assembly line belt plates 1, the assembly line belt plates 1 are fixed on the support frame 2, and a foldable overturnable belt plate 1 is provided between every two assembly line belt plates 1. The belt plate 3, the conveying plane of the overturned belt plate 3 is flush with the conveying plane of the assembly line belt plate 1. When it is necessary to pass, it is only necessary to apply turning power to the reversible belt plate 3, and the reversible belt plate 3 is rotated and pulled down to leave a "passageway" on the entire assembly line, which is convenient for workers to pass through.

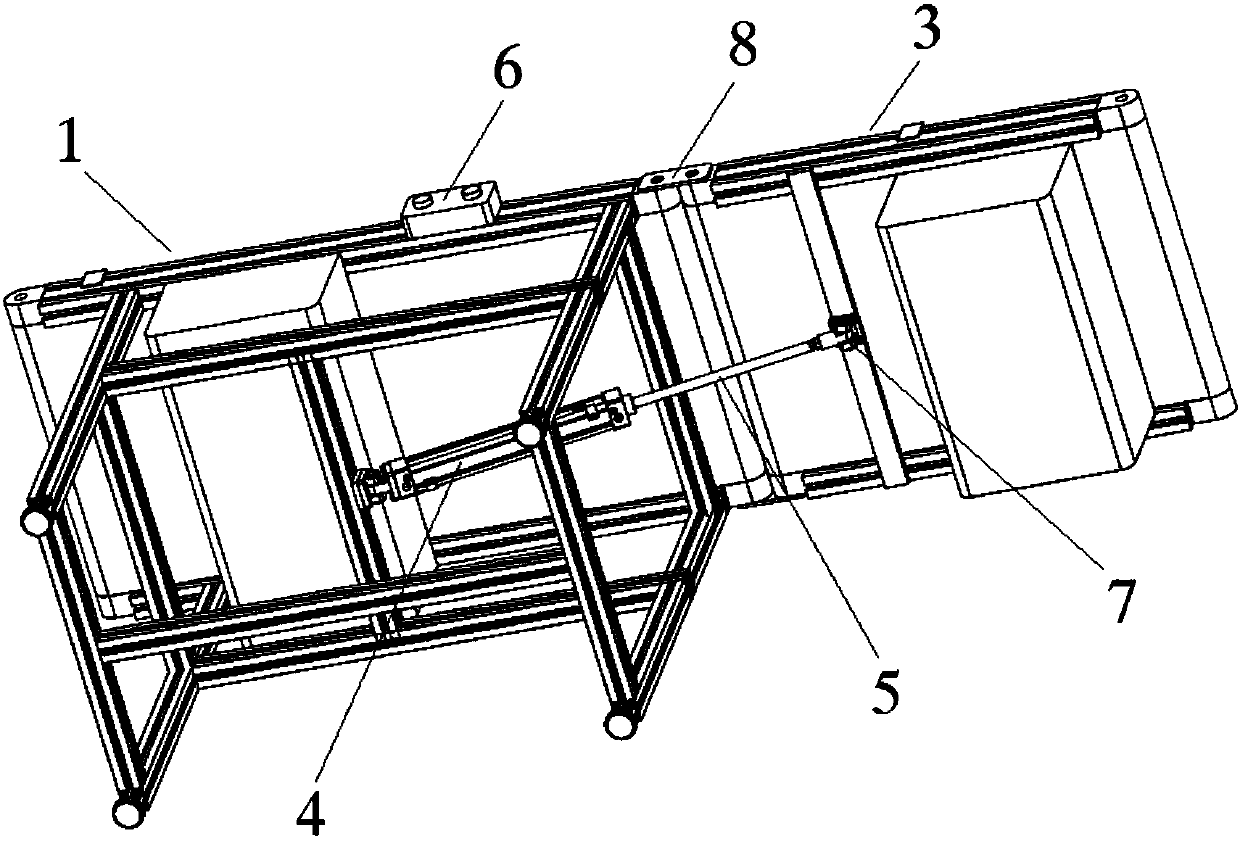

[0021] Such as figure 2 As shown (the angle partial three-dimensional schematic diagram of top view), one end of the overturned belt plate 3 is hinged with one end of one of the assembly line belt plates 1, and the other end of the overturned belt plate 3 is docked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com