Instation hot-line work combined insulation ladder

A technology of combined insulation and internal electrification, applied in ladders, buildings, building structures, etc., can solve the problems of high physical exertion of operators, limited feasibility and practicability, and many peripheral equipment at the operating point, so as to reduce the workload. , convenient operation, strong safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

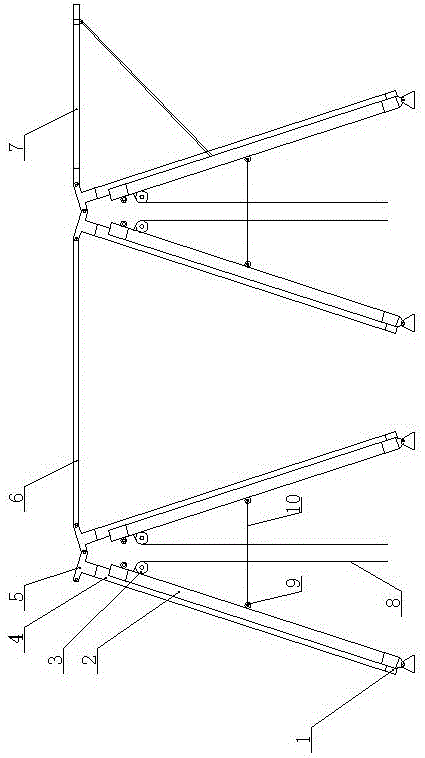

[0012] Example: such as figure 1 As shown, the combined insulation ladder for live work in the station includes at least two sets of symmetrically set up herringbone-shaped support ladders 2, and the support ladders 2 include ladder legs that stand symmetrically on the ground. The sliding ladder 4 is connected, and the sliding ladder head 5 on the top of the sliding ladder 4 on both sides of the same supporting ladder 2 is connected. A retractable flat ladder 6 is fixedly connected between the sliding ladder heads 5 at different support ladders 2 , and an outwardly extending insulating work platform 7 is arranged at the end of the flat ladder 6 .

[0013] The opposite ends of the symmetrical legs of the supporting ladder 2 are provided with pull contacts 9 , and a pull wire 10 is connected between the two pull contacts 9 . Changing the length of the stay wire can adjust the opening angle of the ladder legs, thereby fine-tuning the overall height.

[0014] The upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com