Liquid level control system and method for nuclear power plant circulation water pump pit

A technology of circulating water pump and liquid level control, applied in the direction of pump control, pump, pump device, etc., can solve the problems affecting the reliability of nuclear power plant power generation, failure, water inflow to the bearing chamber, etc., and achieve the effect of eliminating the risk of damage or failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

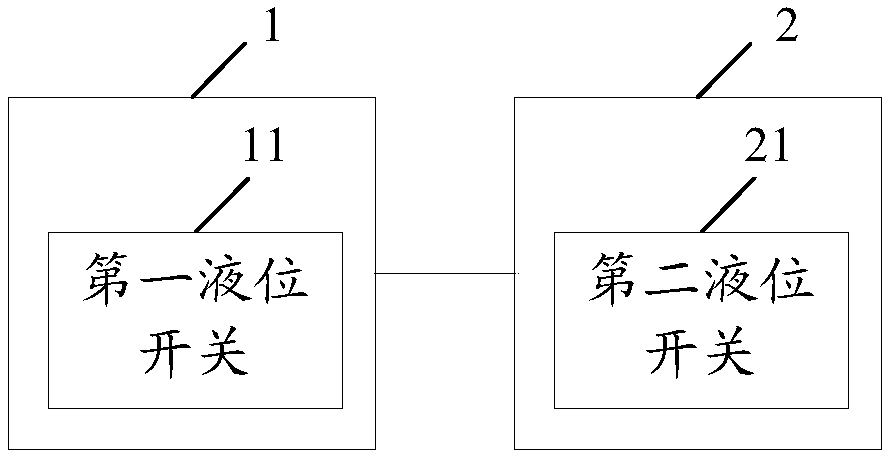

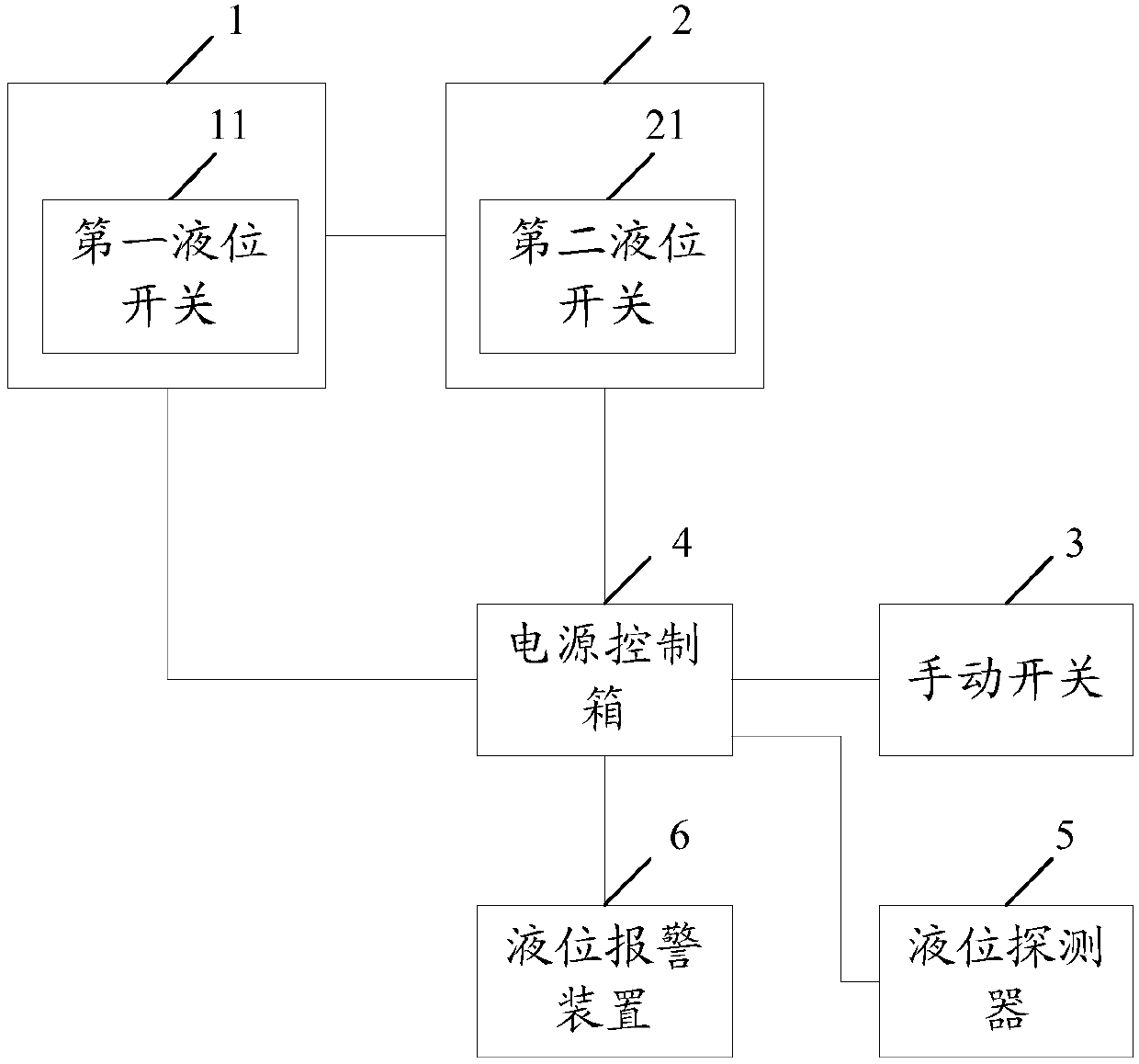

[0034] An embodiment of the present invention provides a liquid level control system for circulating water pump pits of nuclear power plants, see figure 1 , the system can include:

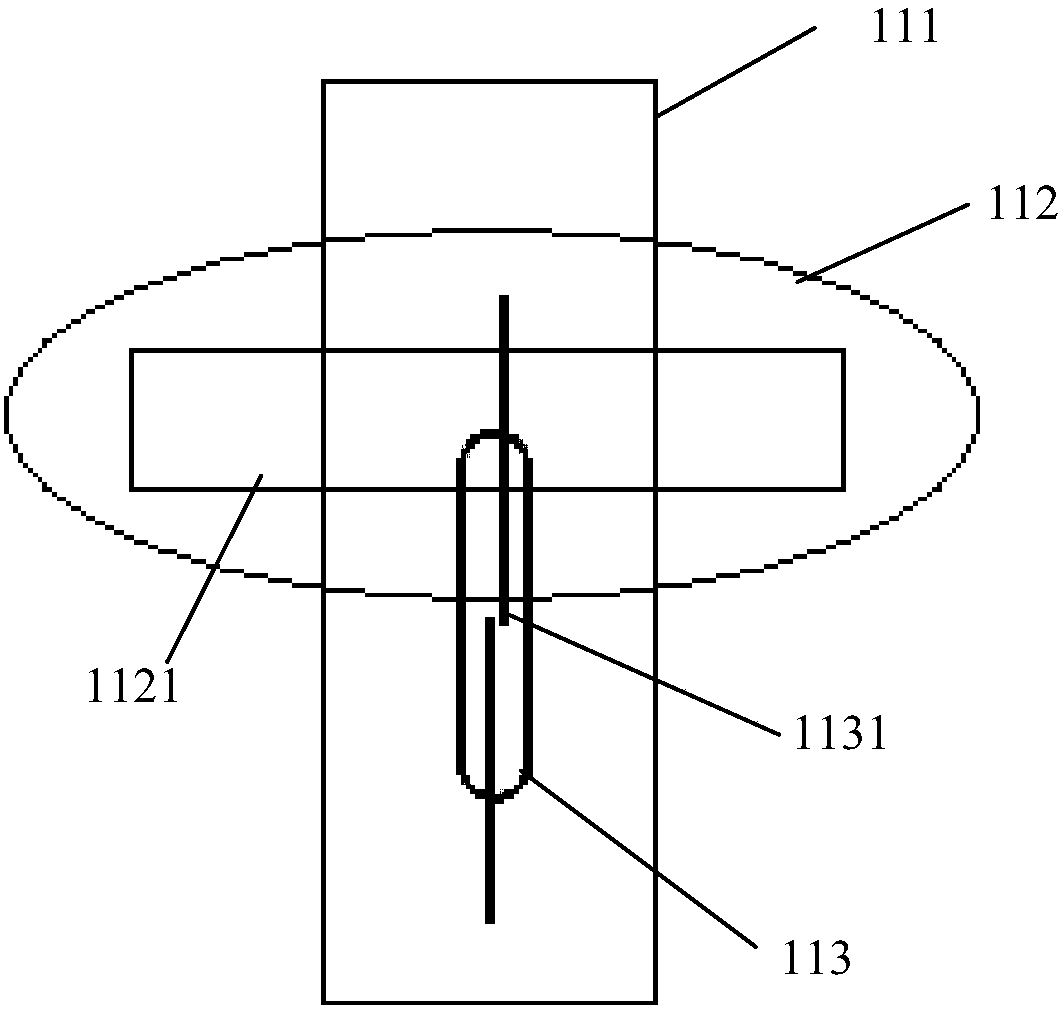

[0035] The main submersible sewage pump 1 is installed in the pump pit of the circulating water pump of the nuclear power plant, and includes a first liquid level switch 11 (which can detect the liquid level information in the pump pit), and the first liquid level switch 11 is used in the pump pit of the circulating water pump of the nuclear power plant. When the liquid level value is greater than or equal to the second liquid level value, start the main submersible sewage pump 1 to start the drainage work of the pump pit; or shut down when the liquid level value in the pump pit of the nuclear power plant circulating water pump is less than or equal to the first liquid level value The main submersible sewage pump 1 is used to stop the drainage of the pump pit, and the second liquid level value is ...

Embodiment 2

[0052] An embodiment of the present invention provides a liquid level control method for a nuclear power plant circulating water pump pit, using the liquid level control system for a nuclear power plant circulating water pump pump pit described in Embodiment 1, see Figure 4 , the method can include:

[0053] Step S21, detecting the liquid level value in the pump pit of the circulating water pump of the nuclear power plant.

[0054] In this embodiment, how to detect the liquid level value in the pump pit will be described in detail in Embodiment 1, and will not be repeated here.

[0055] Step S22, judging whether the detected liquid level value is greater than or equal to the second liquid level value. If the detected liquid level value is greater than or equal to the second liquid level value, step S23 is executed.

[0056] Step S23, start the main submersible sewage pump.

[0057] In this embodiment, the main submersible sewage pump and the backup submersible sewage pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com