A method for the determination of off-flavor substances in the white water of reconstituted tobacco leaves by papermaking

A technology for reconstituted tobacco leaves and papermaking method is applied in the field of determination of odorous substances in white water of reconstituted tobacco leaves by papermaking method, can solve problems such as waste and standard deviation of white water judgment, and achieves the effects of sensitive detection method, simple device structure, and good promotion and application significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

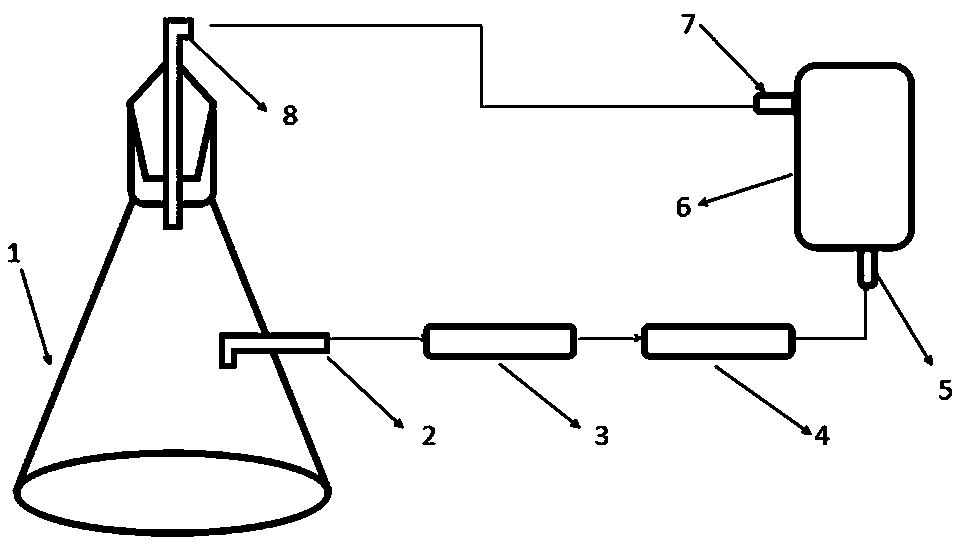

[0032] It should be noted that the method for measuring odorous substances in the white water of reconstituted tobacco leaves provided by the present invention adopts a specific white water odor gas collection device for sample collection, and the collection device is as follows: figure 1 as shown,

[0033] It includes a sampling bottle 1 provided with a gas collection port 2, and a gas sampling pump 6 connected to the gas collection port 2;

[0034] The sampling pump outlet 7 of the gas sampling pump 6 is connected with the gas return port 8 on the sampling bottle 1;

[0035] An odor substance adsorption device 4 is provided between the gas collection port 2 and the gas sampling pump 6, and the odor substance adsorption device 4 is connected to the sampling pump inlet 5 of the gas sampling pump 6;

[0036] A water removal adsorption pipe 3 is provided between the gas collection port 2 and the odor substance adsorption device 4;

[0037] Gas collection port 2, water removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com