Double-sided turning cutting tool clamping mechanism and method for thin-wall uniform-thickness parts

A clamping mechanism and cutting tool technology, applied in the direction of tool holders, etc., can solve the problems of restricting the mass production of parts, the parallelism and flatness of the upper and lower end faces are difficult to meet the processing requirements, and the thickness dimension, parallelism and flatness are easily out of tolerance, etc. To achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

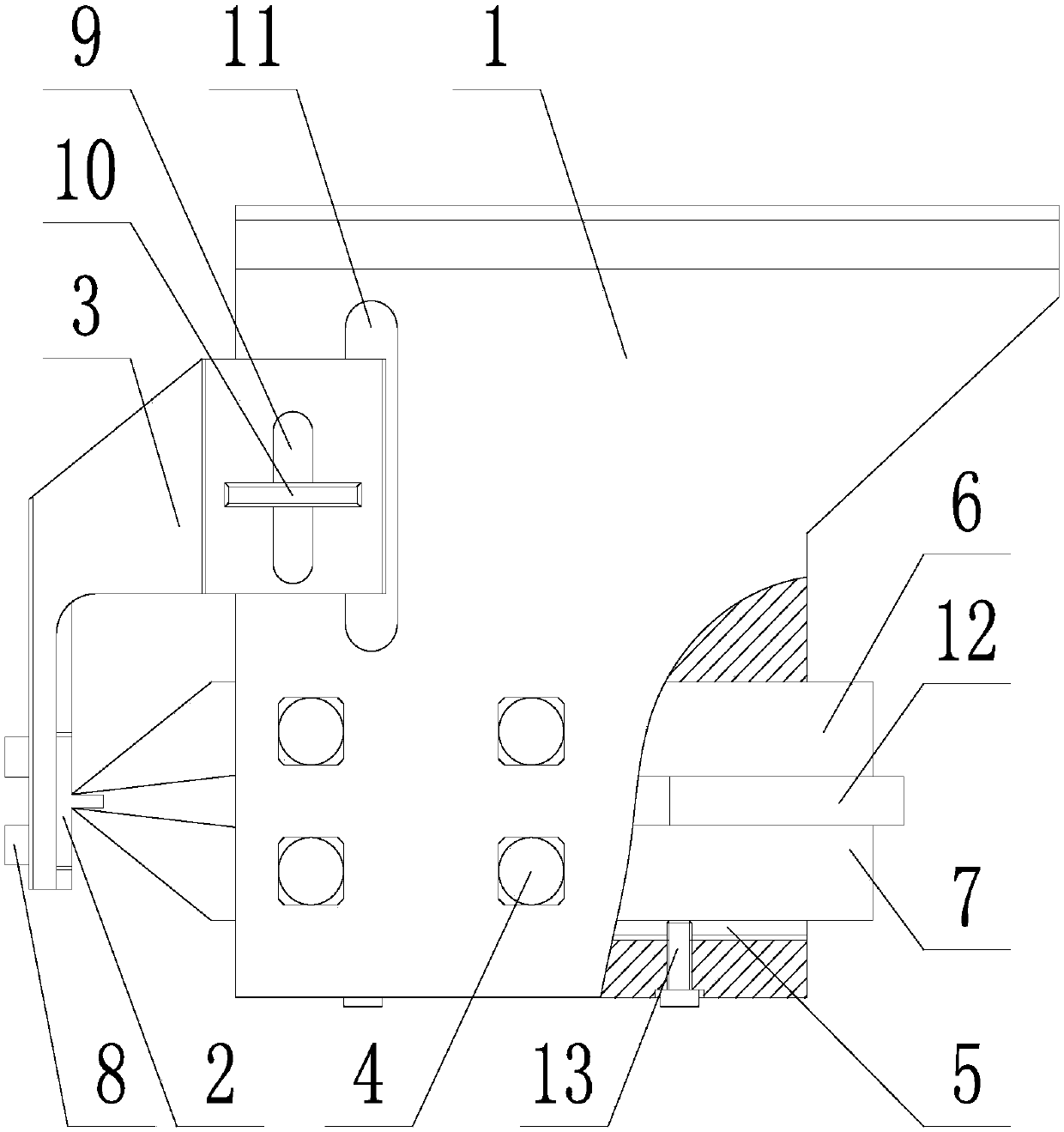

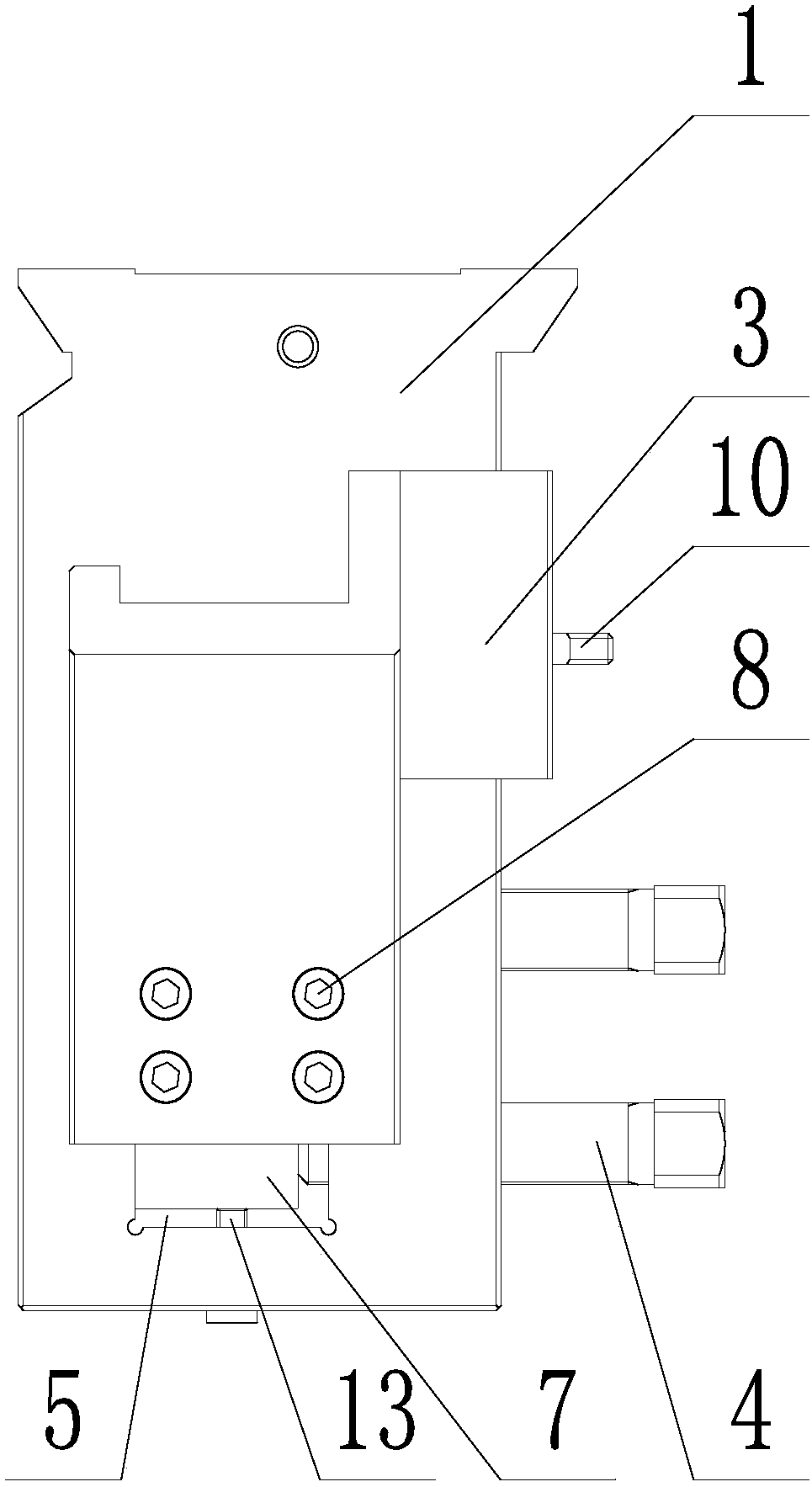

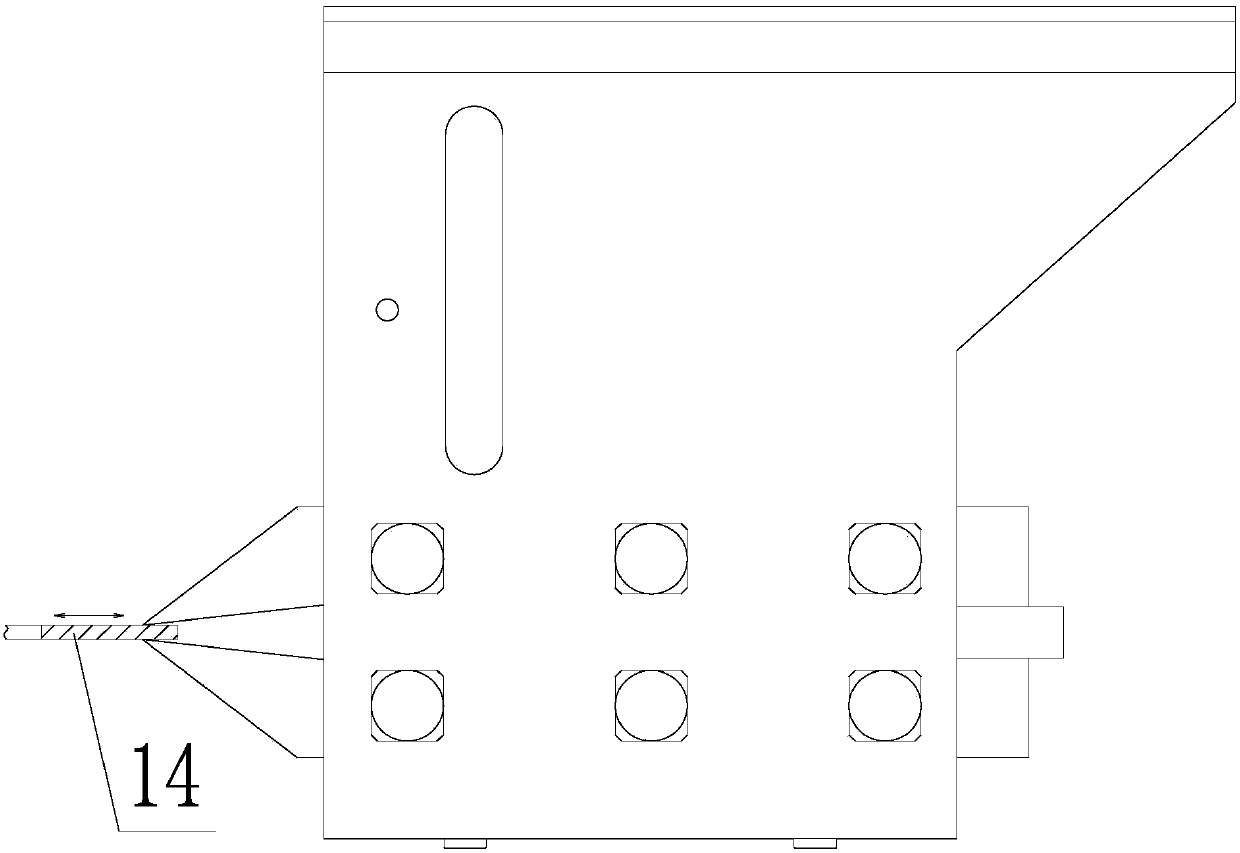

[0025] Such as figure 1 , 2 As shown, a tool clamping mechanism for double-sided turning of thin-walled and thick parts includes a tool holder body 1, a tool setting block 2, a tool setting block mounting frame 3 and a tool fastening bolt 4; the tool holder body 1 The top adopts a dovetail slide rail structure, and the tool holder main body 1 is connected with the machine tool holder through the top dovetail slide rail structure; a tool mounting hole 5 is opened at the lower part of the tool holder main body 1, and a The upper and lower turning tools are divided into an upper turning tool 6 and a lower turning tool 7. The upper turning tool 6 and the lower turning tool 7 are arranged in parallel and the tool tips are facing each other; Two rows of tool fastening bolts 4 are distributed, the upper row of tool fastening bolts 4 cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com