Iron tower welding center

A technology of iron towers and welding robots, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding efficiency, wasting time and manpower, etc., to increase the welding operation space, improve work efficiency, Avoid the effect of manual repair welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

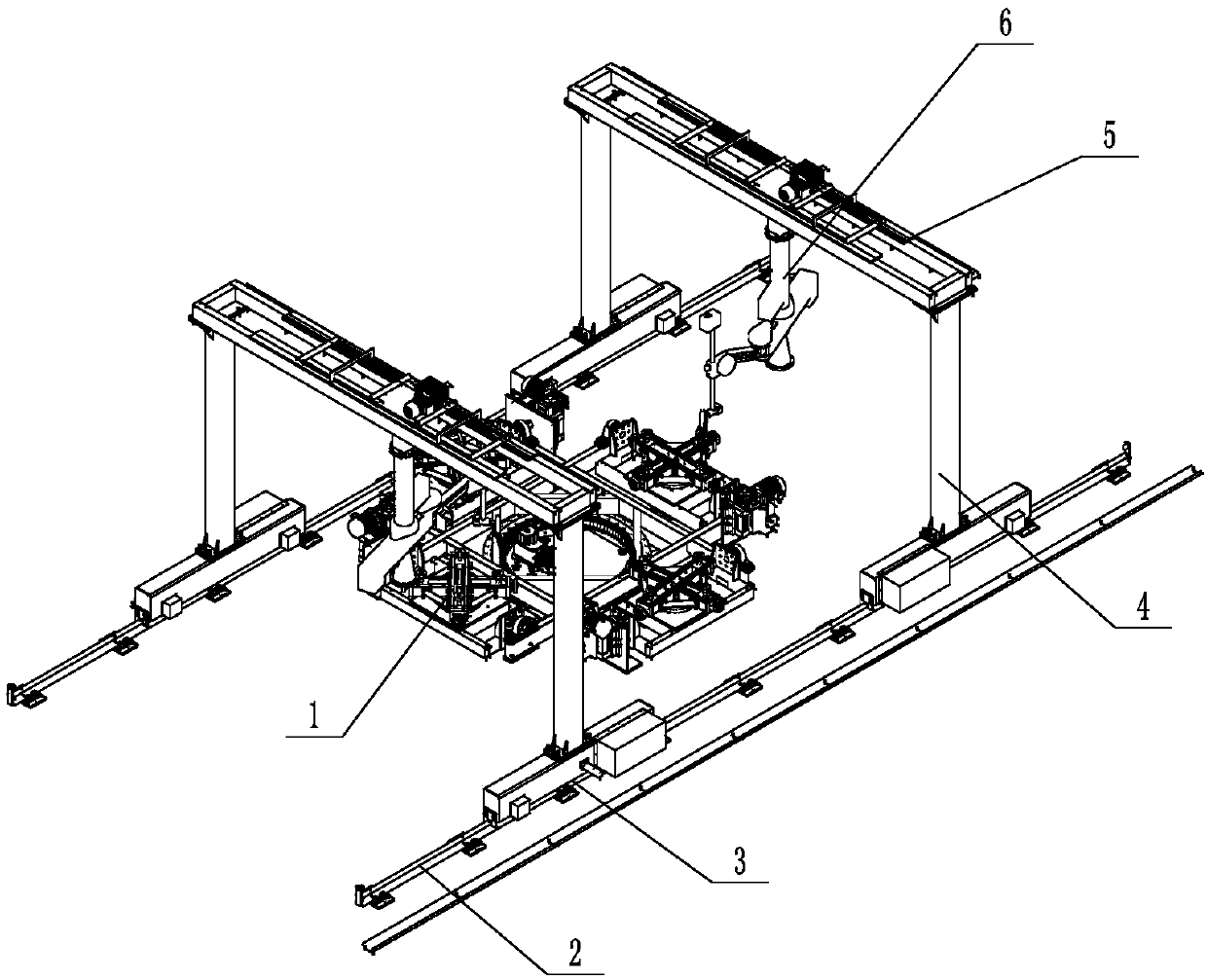

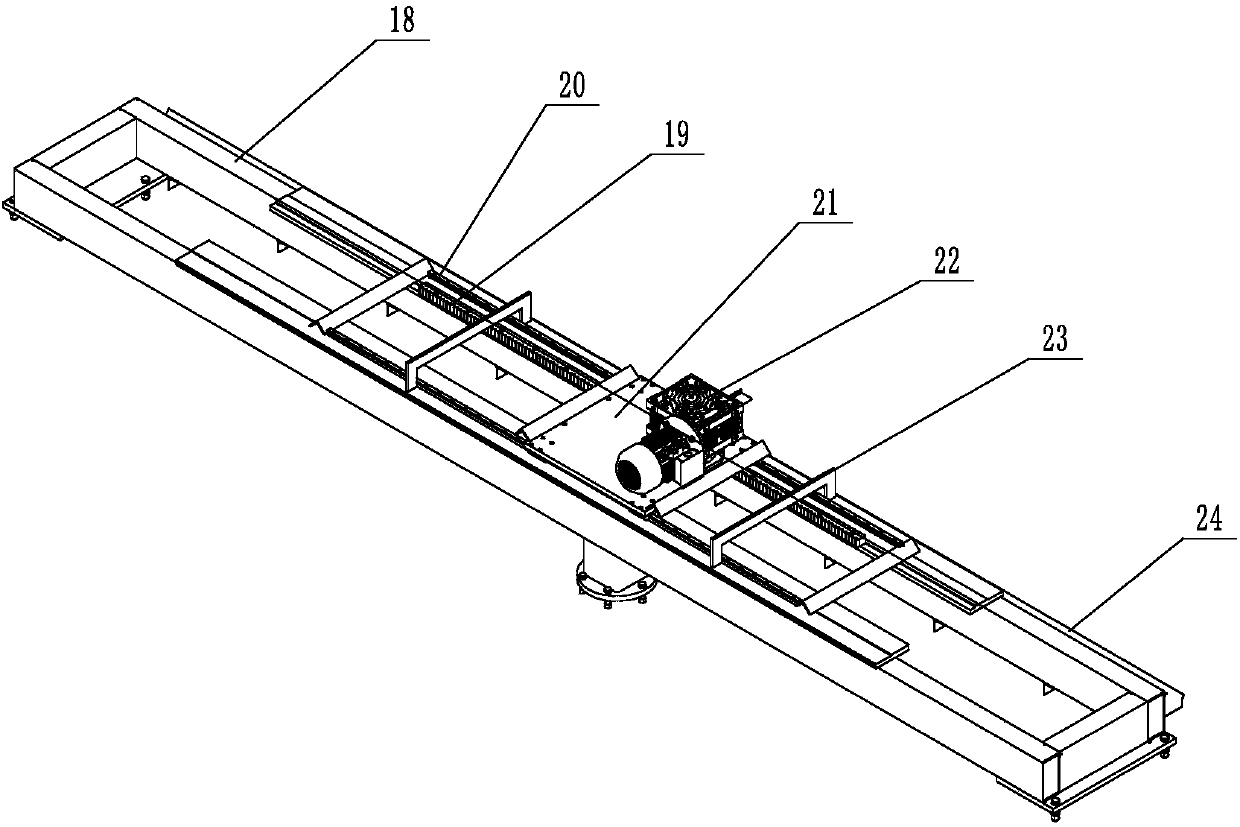

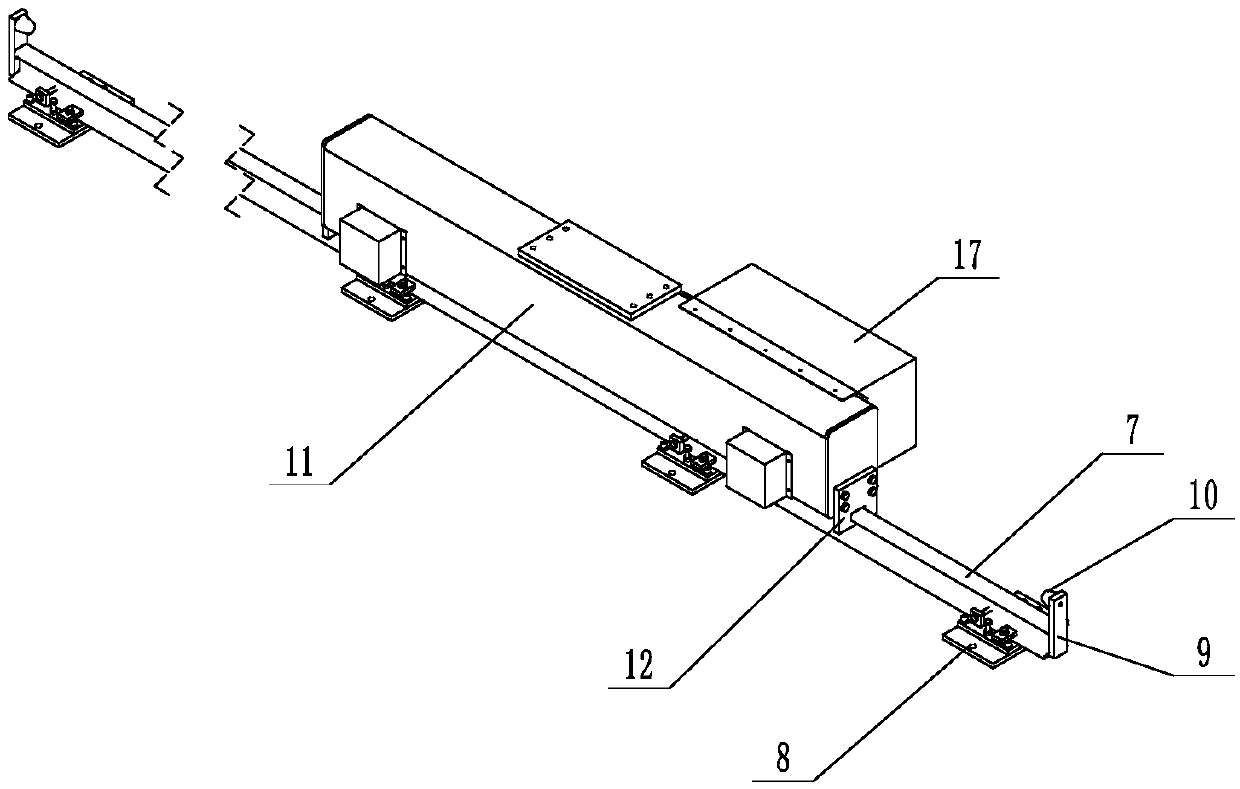

[0018] Such as Figure 1-4 As shown, the present invention includes a four-position rotary positioner 1, the two sides of the positioner 1 are provided with parallel guide rails 2, and the upper end of the guide rail 2 is connected with four column assemblies 4 through a walking trolley 3, and each two The upper end of each column assembly 4 is fixedly connected with a beam assembly 5, and the lower end of the beam assembly 5 is respectively provided with a welding robot 6 matched with the positioner 1. Guide rail 2 comprises the track 7 that section is I-shaped, and the lower end of track 7 is provided with a plurality of evenly distributed track seats 8, and the two ends of this track seat 8 are fixedly connected with buffer frame 9, and the side wall of buffer frame 9 is provided with The buffer block 10 that walking dolly 3 cooperates.

[0019] The walking trolley 3 includes a car body 11, the two ends of the car body 11 are provided with a scraper 12 matching the track 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com