An automobile pedal positioning welding device

A technology of positioning welding and automobile pedals, which is applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of inability to achieve comprehensive welding, and achieve the effects of avoiding manual repair welding, avoiding slag inclusion, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

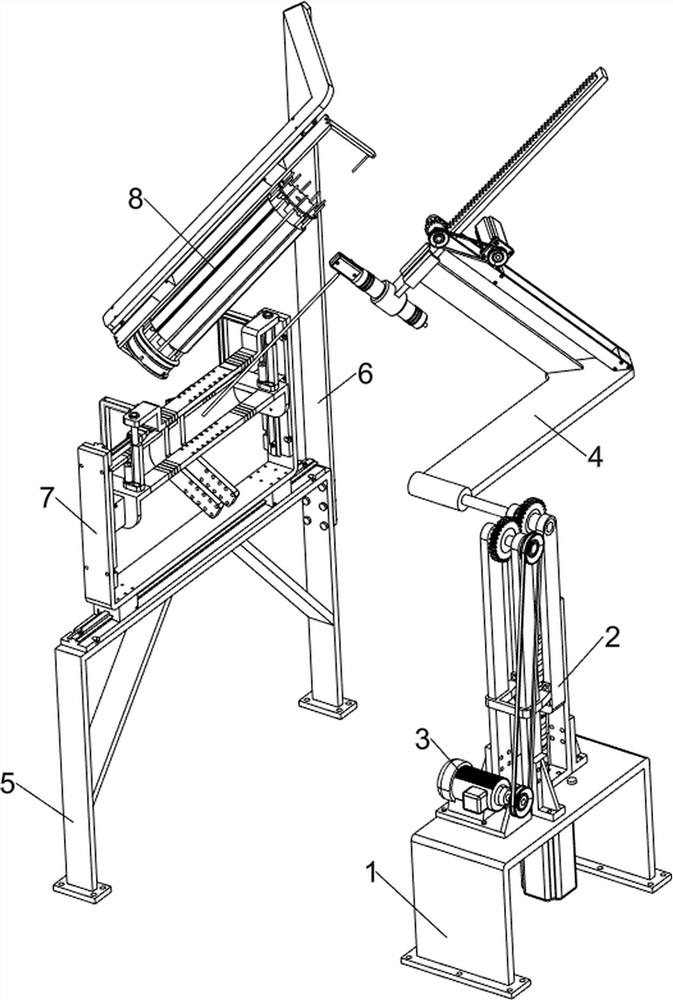

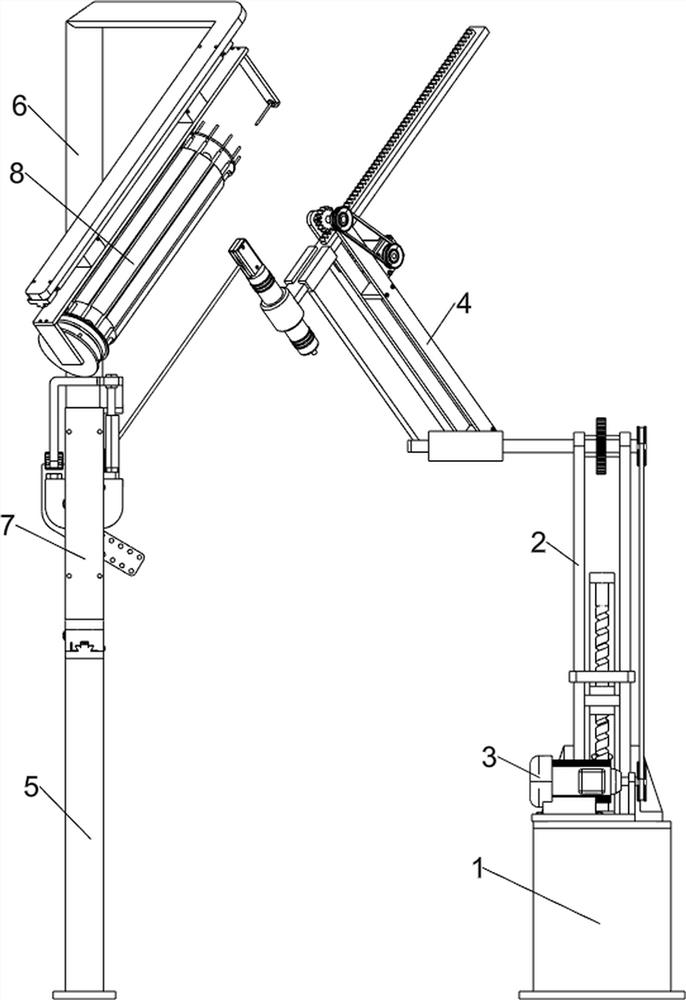

[0034] Car pedal positioning welding device, such as Figure 1-4 As shown, including the first mounting frame 1, the lifting assembly 2, the first rotating assembly 3 and the welding mechanism 4; the rear portion of the first mounting frame 1 is connected to the lifting assembly 2; the first mounting frame 1 front connection has the first A rotating assembly 3, and the first rotating assembly 3 is connected to the lifting assembly 2; the upper portion of the lifting assembly 2 is connected to the welding mechanism 4, the welding mechanism 4 is used to weld the pedal and the pedal arm.

[0035] When using a car pedal to position the welding device, first install the debugging, then turn on the power, manually will be used for car brakes, clutches and throttles, and are located in the work area of the welding mechanism 4, this The pedal and the pedal arm welded portion are brought together, the pedal is vertically placed, the pedal arm is facing down, and then controls the first ro...

Embodiment 2

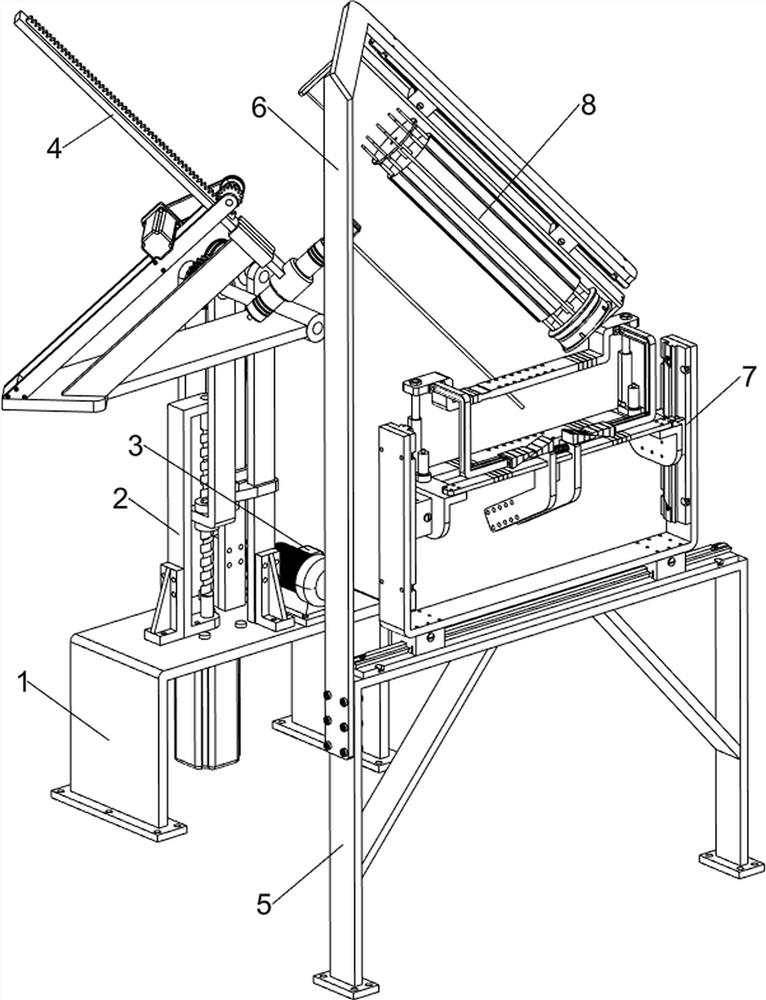

[0037] On the basis of Example 1, if Figure 5 , Figure 7 with Figure 8 As shown, the welding mechanism 4 includes a fixing sleeve 401, a second connecting plate 402, a third connecting plate 403, a guide rail 404, a slide plate 411, a soldering torch 413, a first pinch plate 414, a curved groove 414a, a semi-circular hole groove 414b. The second pinch plate 415 and the electrode 416; the upper portion of the lifting assembly 2 is fixedly connected to the fixing sleeve 401; the rear side of the fixing sleeve 401 is fixedly connected to the second connecting plate 402; the second connecting plate 402 has a third connection. Board 403; the tip of the third connecting plate 403 is welded with guide slide rail 404; the guide rail 404 slides to be connected to the slide 411; the bottom portion of the slide plate 411 is fixedly connected to the solder torch 413; the upper portion of the solder torch 413 is fixedly connected to the first pinch plate 414; first pinch plate The clamping sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com