Bicycle single-side oil pressure disc brake lower pump

A bicycle, unilateral technology applied to hydraulic disc brakes. It can solve the problems of small friction disc clearance, slow oil cylinder recovery, difficult adjustment, etc., to achieve the effect of simple and convenient adjustment and improved feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with implementation.

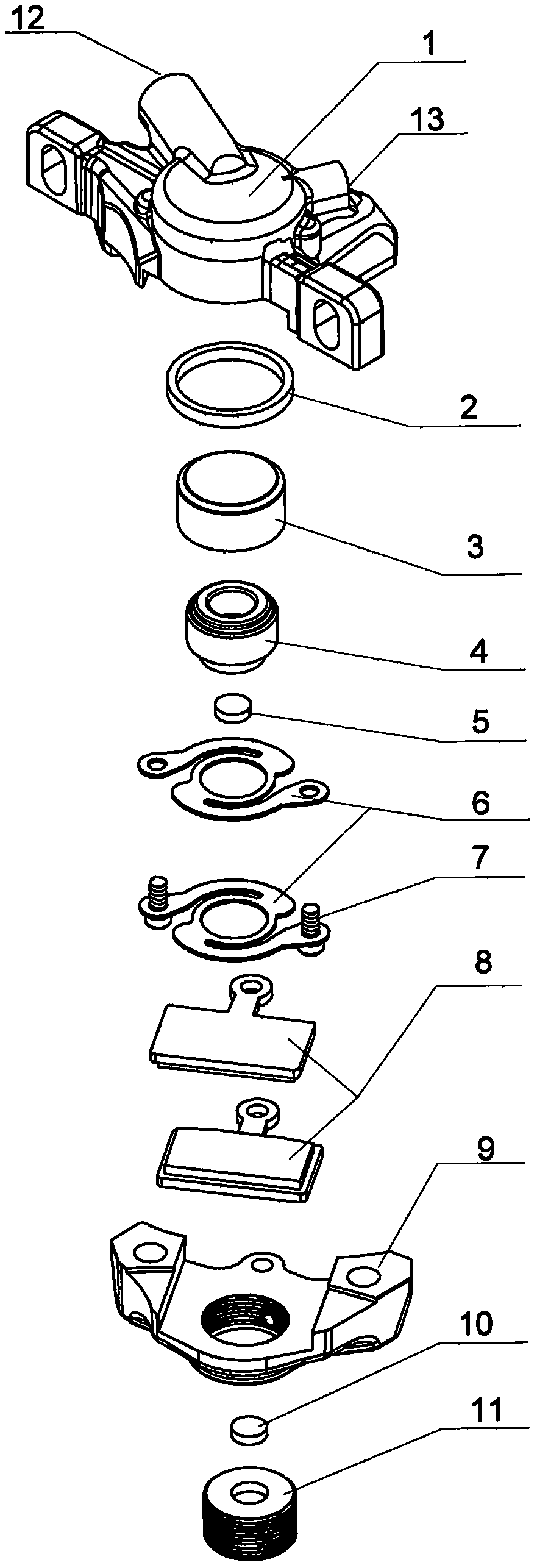

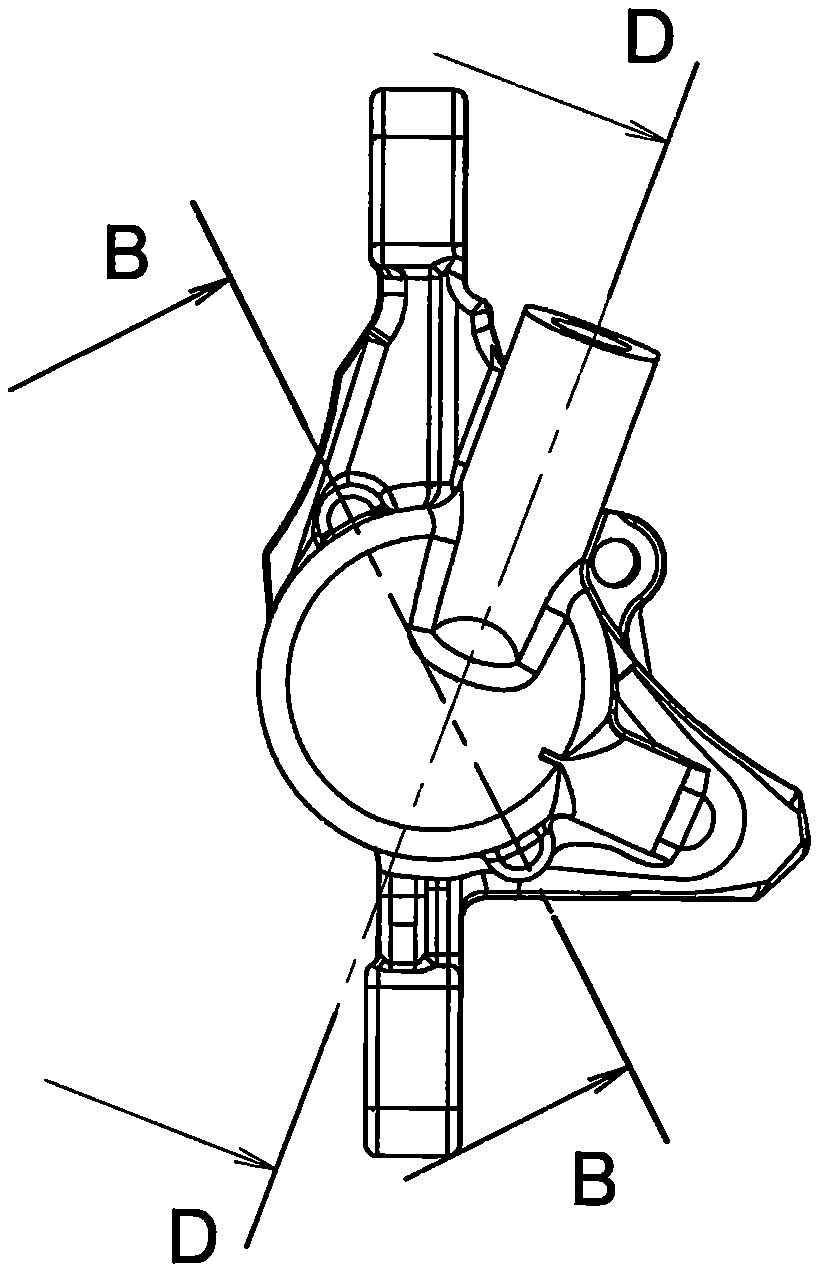

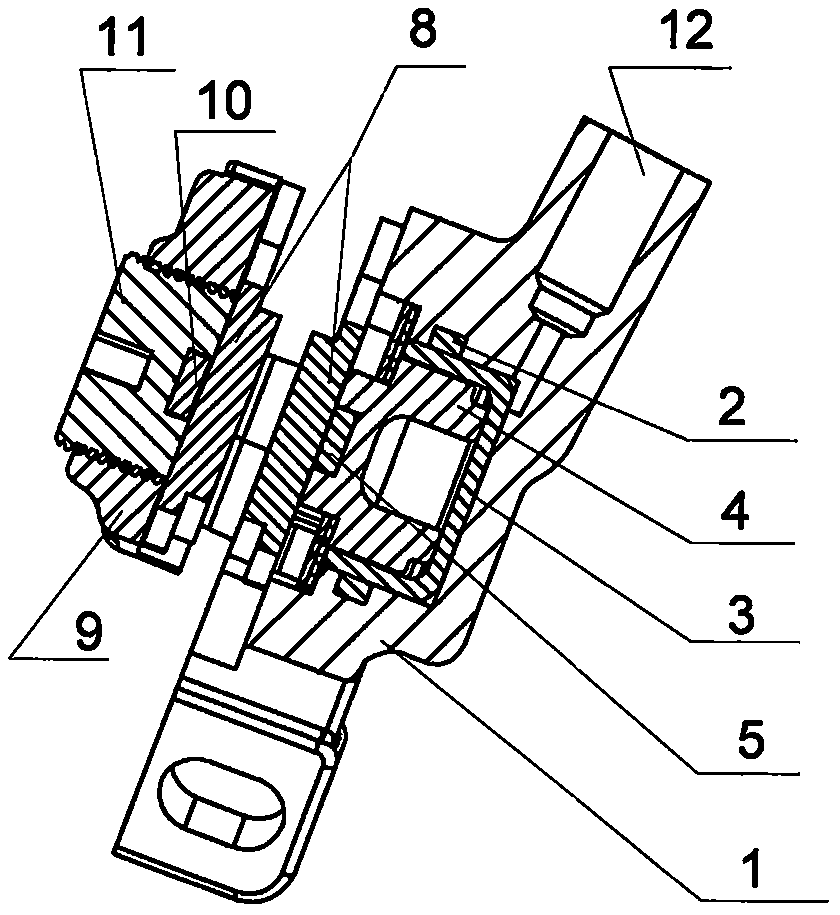

[0014] figure 1 It is a three-dimensional exploded view of a specific embodiment of the bicycle unilateral hydraulic disc brake lower pump of the present invention, combined with figure 2 , image 3 and Figure 4 Explain as follows: main formation of the present invention is tongs body 1, sealing ring 2, oil cylinder 3, heat-insulating jack post 4, left magnet 5, stage clip 6, small pliers body 9, right magnet 10 and adjusting screw 11. The large pliers body 1 has a cylinder hole to accommodate the oil cylinder 3, and the outer edge of the cylinder hole has a groove to accommodate the compression spring 6; the compression spring 6 is made of steel sheet or steel wire, and its elastic force presses the oil cylinder 3 and heat insulation in static state. The top column 4 and the compression spring 6 are fixed on the tong body 1 by screws or the compression spring 6 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com