Crane telescopic arm cylinder pin centring position detection device

A technology of detection device and telescopic arm, which is applied in the direction of cranes, transportation and packaging, load hanging components, etc., can solve problems such as low efficiency, inability to accurately find the neutral position, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

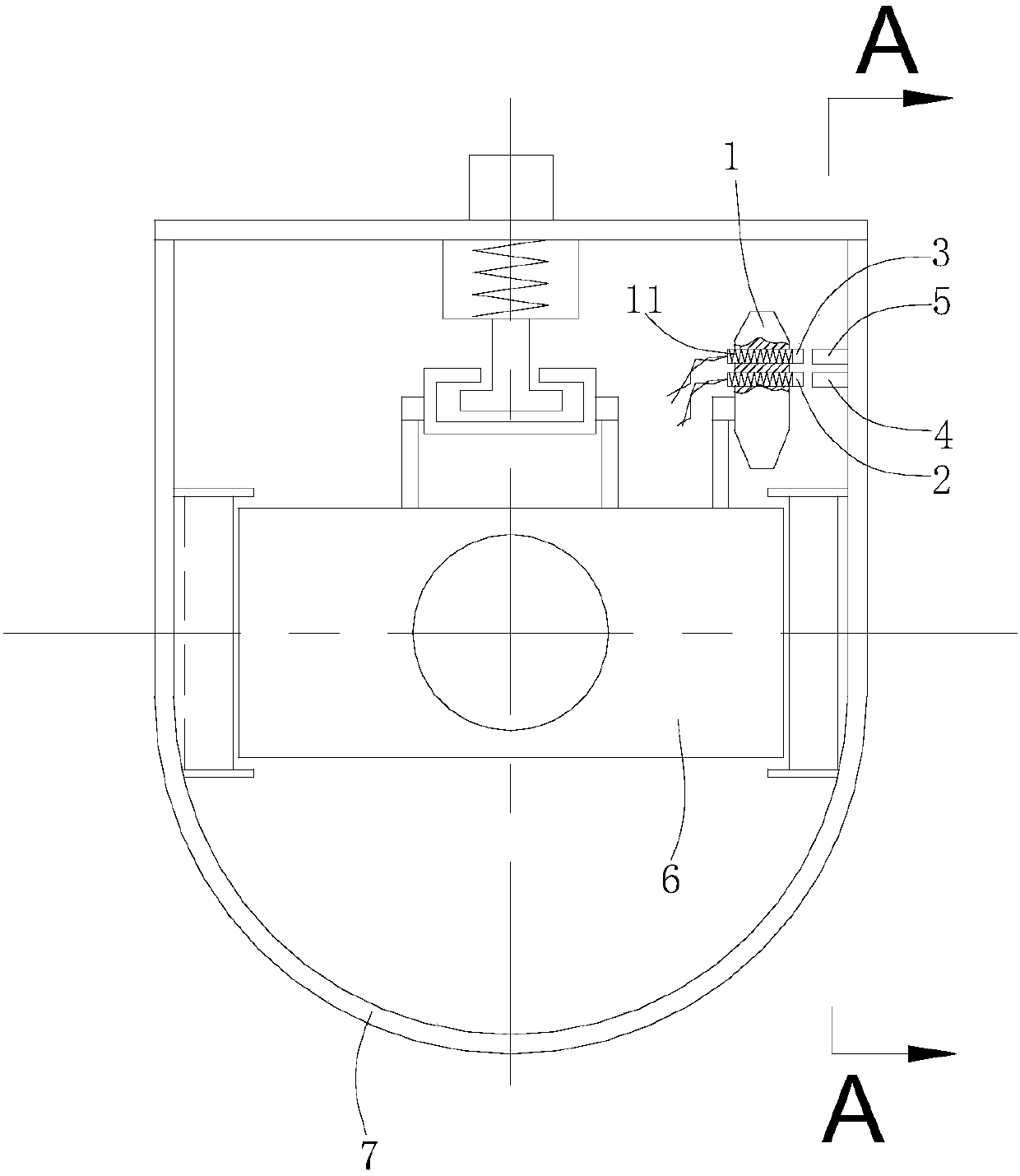

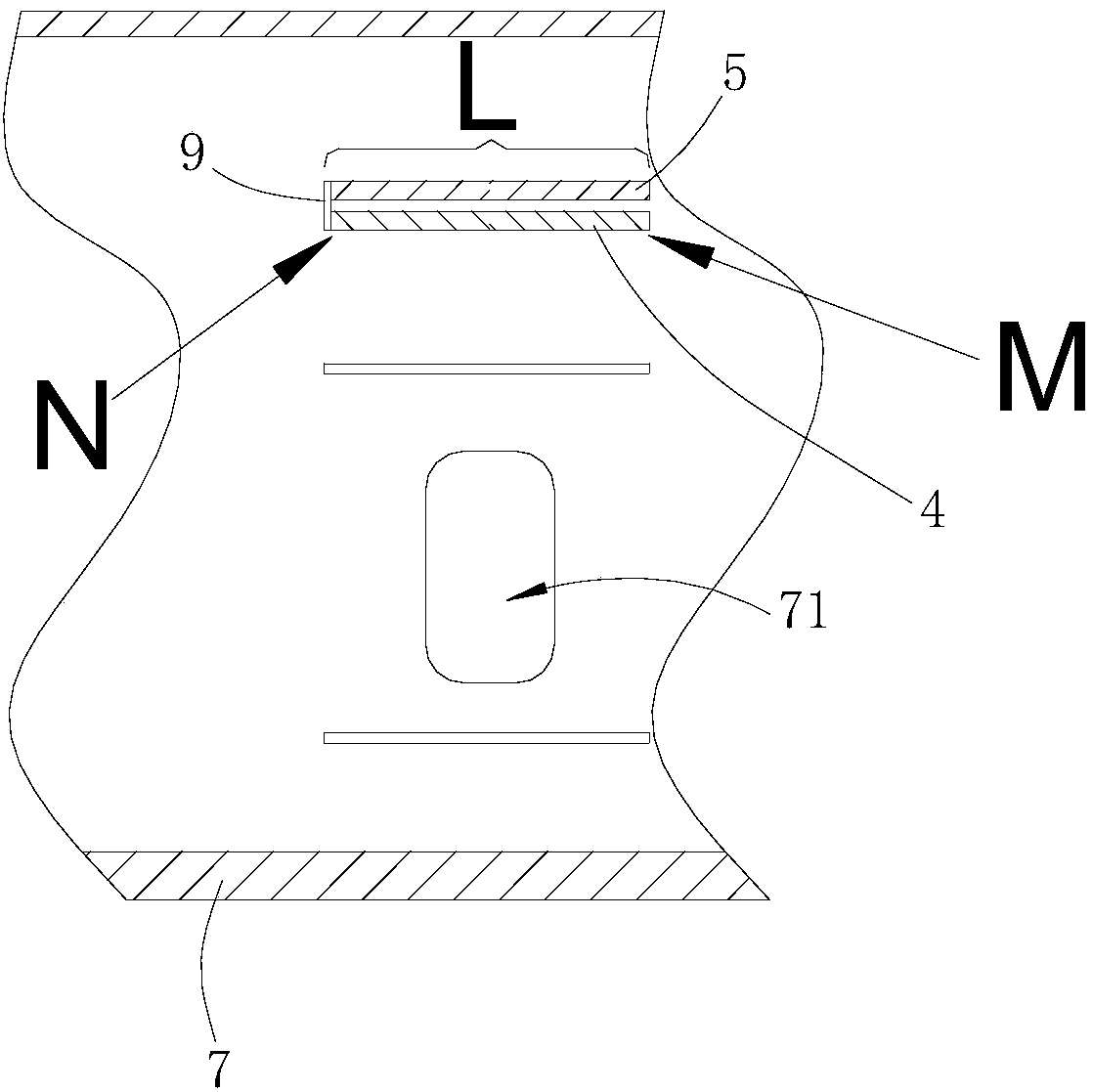

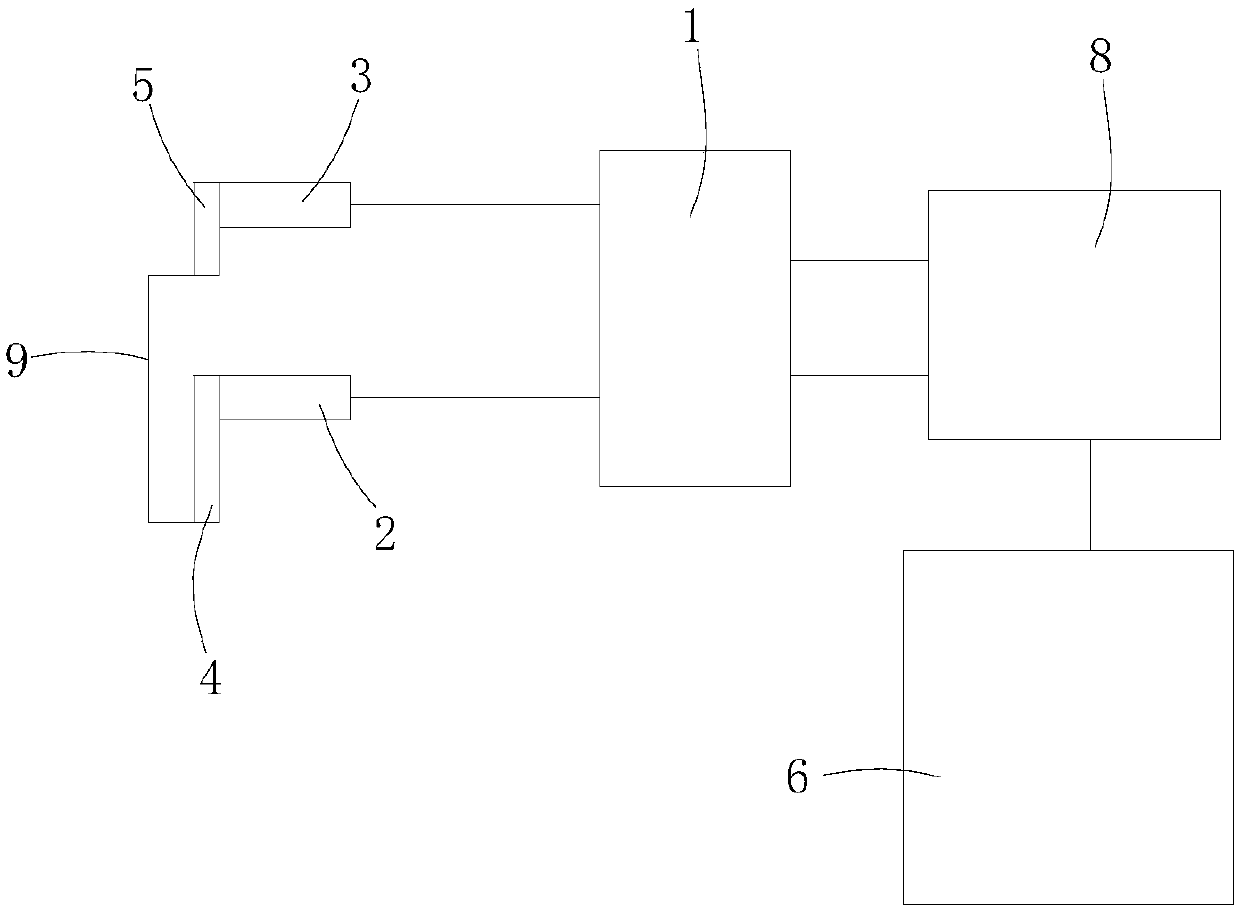

[0019] Such as Figures 1 to 3 shown.

[0020] The detection device includes a detection module 1 , a resistance sliding rail 4 , a conductive block 5 , a first contact piece 2 and a second contact piece 3 .

[0021] The detection module 1 is fixed on the telescopic oil cylinder 6, and the first contact piece 2 and the second contact piece 3 are respectively fixed on the detection module 1 by the reed 11 (that is, the first contact piece 2 and the second contact piece 3 are equivalent to being fixed on the telescopic On the oil cylinder 6), the first contact piece 2 and the second contact piece 3 are respectively aligned with the inner wall of the boom section 7, and the first contact piece 2 and the second contact piece 3 communicate with the detection module 1 through wires respectively.

[0022] The resistance slide rail 4 and the conductive block 5 are fixed on the inner wall of the boom section 7, and the position of the resistance slide rail 4 and the conductive block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com