Environment-friendly method for ultrasonically synthesizing CsPbBr3 nano-crystals with different structures

A technology of ultrasonic synthesis and nanocrystals, applied in nanotechnology, chemical instruments and methods, luminescent materials, etc., can solve the problems of easy damage to the crystal structure, pollution of the environment, etc., and achieve the effects of wide application prospects, cheap raw materials, and high fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

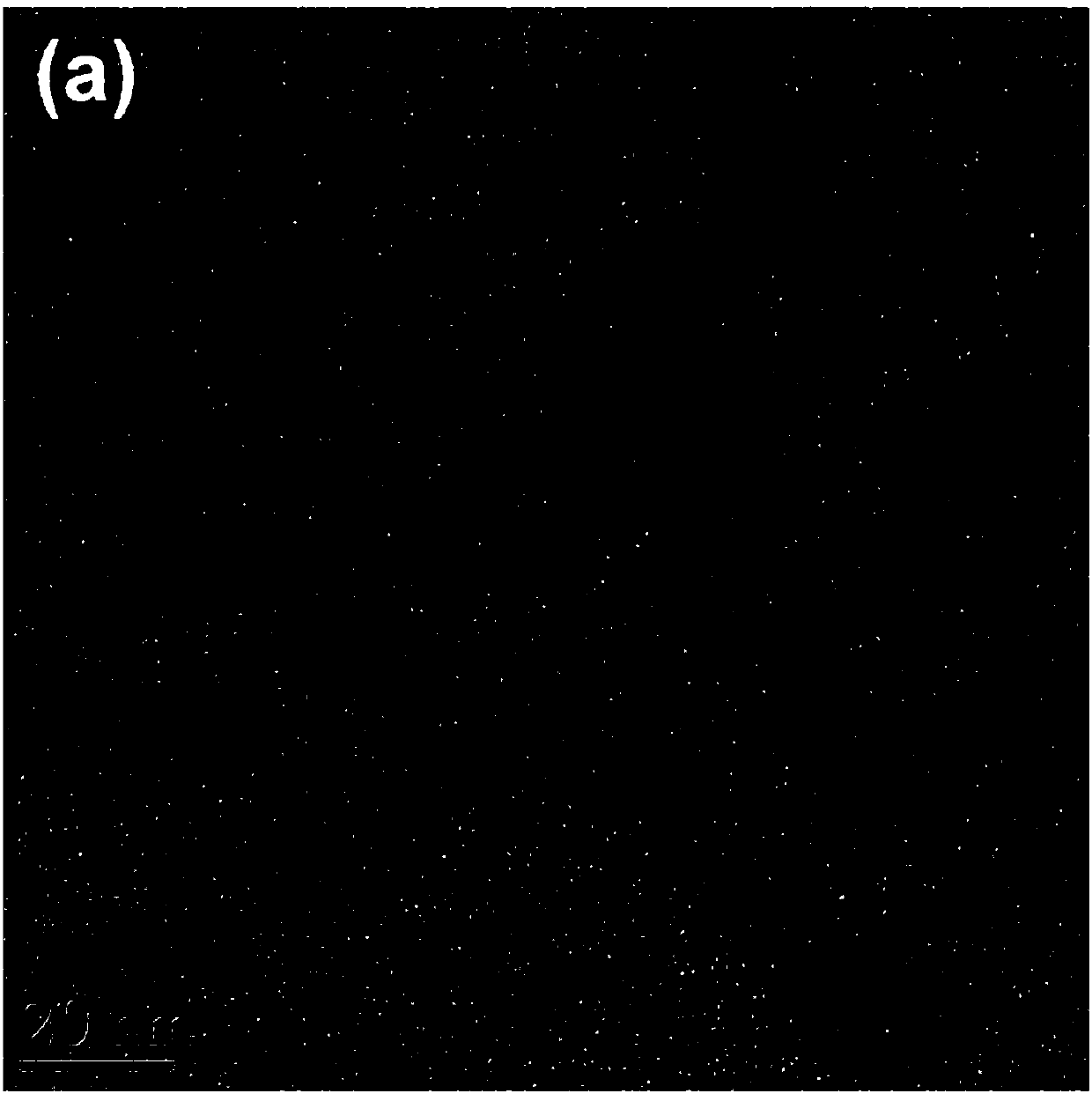

[0032] Green Ultrasonic Preparation of CsPbBr 3 The nanocrystal solution specifically comprises the following steps:

[0033] (1) Add 0.1mmol of Cs 2 CO 3 and 0.2 mmol PbBr 2 Add to 1ml of liquid paraffin, then drop in 0.9ml of oleic acid and 0.1ml of oleylamine to obtain a pale yellow mixed solution;

[0034] (2) Place the light yellow mixed solution in step (1) in a contact ultrasonic machine, set the cycle curve of ultrasonication for 1 min and stop for 5 s, the total ultrasonic time is 30 min, and the ultrasonic power is 90W, to obtain a green mixed solution;

[0035] (3) Centrifuge the green mixed solution of step (2) directly at 5000 rpm for 20 min, pour off the supernatant, and then redisperse the precipitate in toluene to obtain crude CsPbBr 3 nanocrystal solution;

[0036] (4) The crude CsPbBr obtained in step (3) 3 The nanocrystal solution was centrifuged again at 8000 rpm for 10 min, and then the precipitate was redispersed in toluene to obtain more pure CsPbB...

Embodiment 2

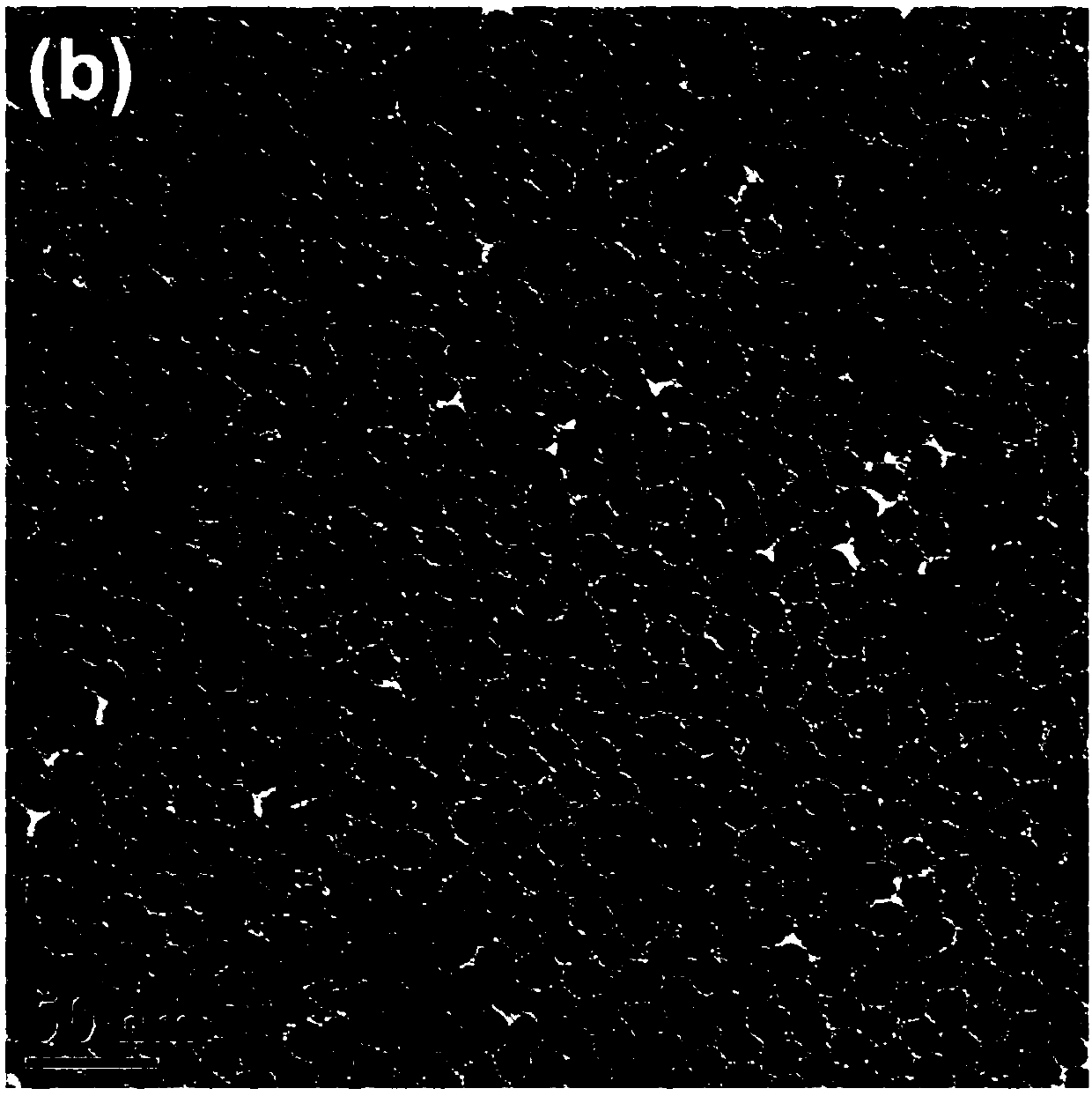

[0039] Green Ultrasonic Preparation of CsPbBr 3 The nanocrystal solution specifically comprises the following steps:

[0040] (1) Add 0.1mmol of Cs 2 CO 3 and 0.5 mmol PbBr 2 Add to 5ml of liquid paraffin, then drop in 0.5ml of oleic acid and 0.5ml of oleylamine to obtain a mixed solution;

[0041] (2) Put the mixed solution in step (1) in a contact ultrasonic machine, set the cycle curve of ultrasonic for 1 min and stop for 5 s, the total ultrasonic time is 60 min, and the ultrasonic power is 90W, to obtain a green mixed solution;

[0042] (3) Centrifuge the green mixed solution of step (2) directly at 8000 rpm for 10 min, pour off the supernatant, and then redisperse the precipitate in toluene to obtain crude CsPbBr 3 nanocrystal solution;

[0043] (4) The crude CsPbBr obtained in step (3) 3 The nanocrystal solution was centrifuged again at 10,000 rpm for 10 min, and then the precipitate was redispersed in toluene to obtain more pure CsPbBr 3 nanocrystals.

[0044] Pre...

Embodiment 3

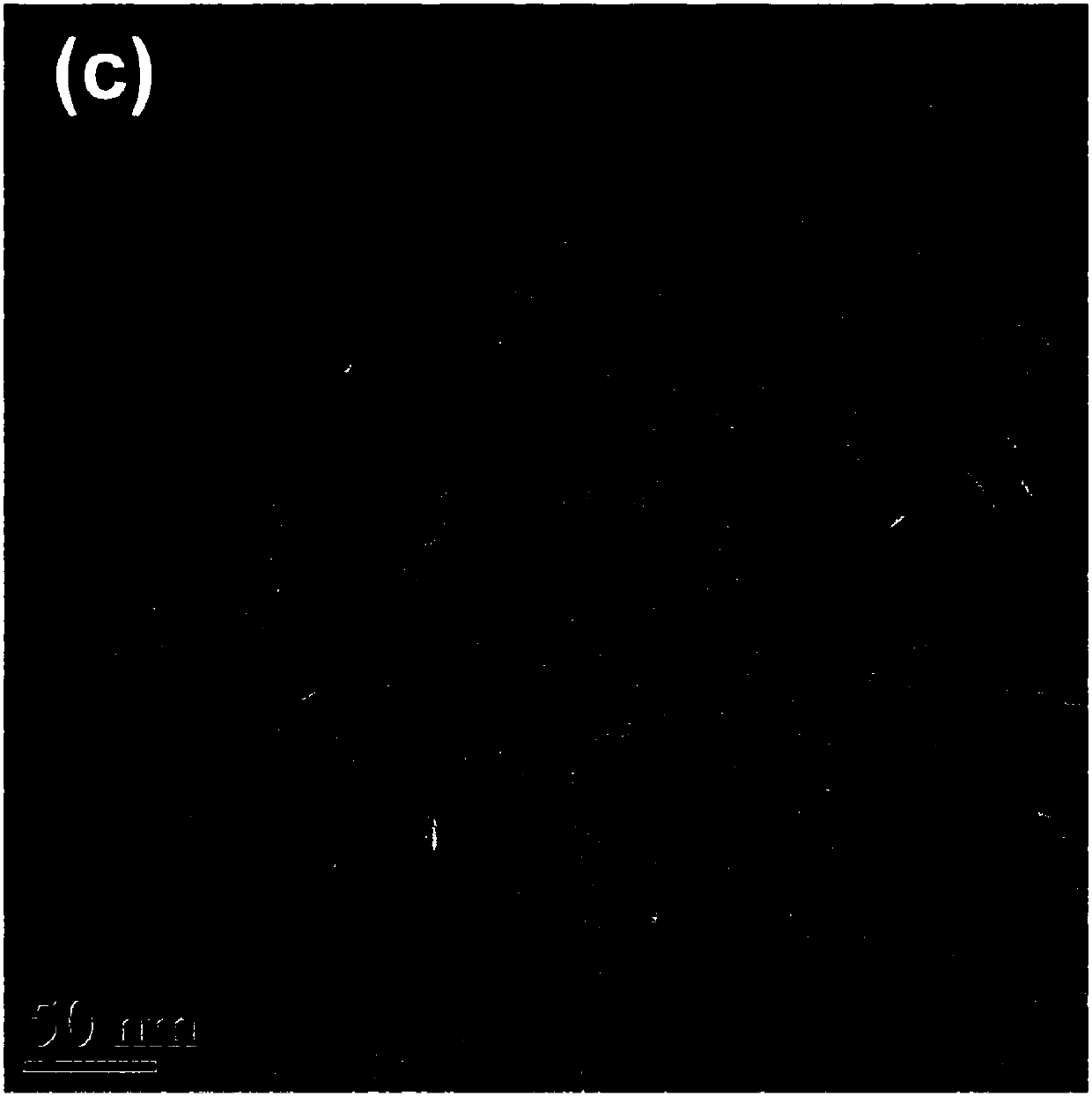

[0046] Green Ultrasonic Preparation of CsPbBr 3 The nanocrystal solution specifically comprises the following steps:

[0047] (1) Add 0.1mmol of Cs 2 CO 3 and 0.2 mmol PbBr 2 Add to 10ml of liquid paraffin, then drop in 0.1ml of oleic acid and 1.0ml of oleylamine to obtain a mixed solution;

[0048] (2) Put the mixed solution in step (1) in a contact ultrasonic machine, set the cycle curve of ultrasonic for 1 min and stop for 5 s, the total ultrasonic time is 30 min, and the ultrasonic power is 200W, to obtain a green mixed solution;

[0049] (3) Centrifuge the green mixed solution in step (2) directly at 8000 rpm for 20 min, pour off the supernatant, and then redisperse the precipitate in toluene to obtain crude CsPbBr 3 nanocrystal solution;

[0050] (4) The crude CsPbBr obtained in step (3) 3 The nanocrystal solution was centrifuged again at 12000 rpm for 5min, and then the precipitate was redispersed in toluene for storage to obtain more pure CsPbBr 3 nanocrystals. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap