Suspended-ceiling assembled steel frame transfer story

A transfer layer, prefabricated technology, applied in the direction of ceiling, building components, buildings, etc., can solve the problems of affecting construction efficiency, affecting the strength of transfer layer, inconvenience, etc., and achieve the effect of flexible and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

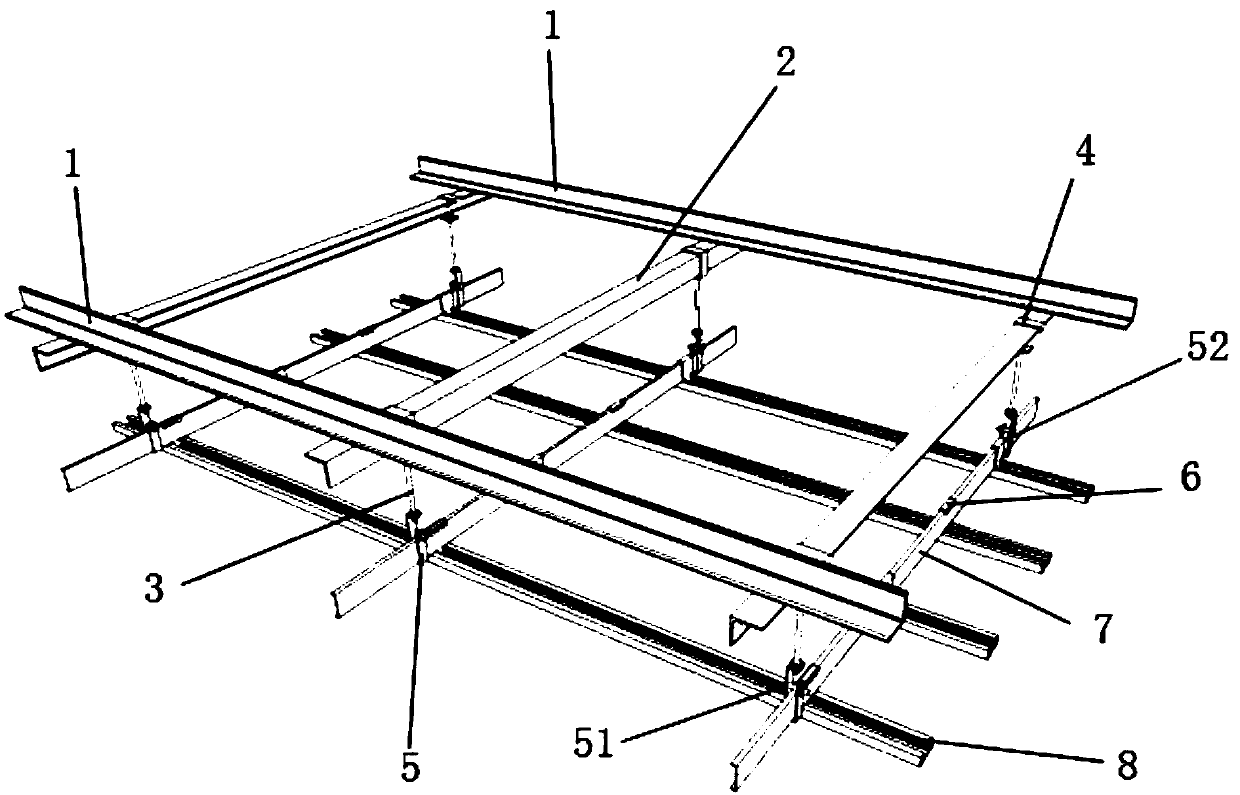

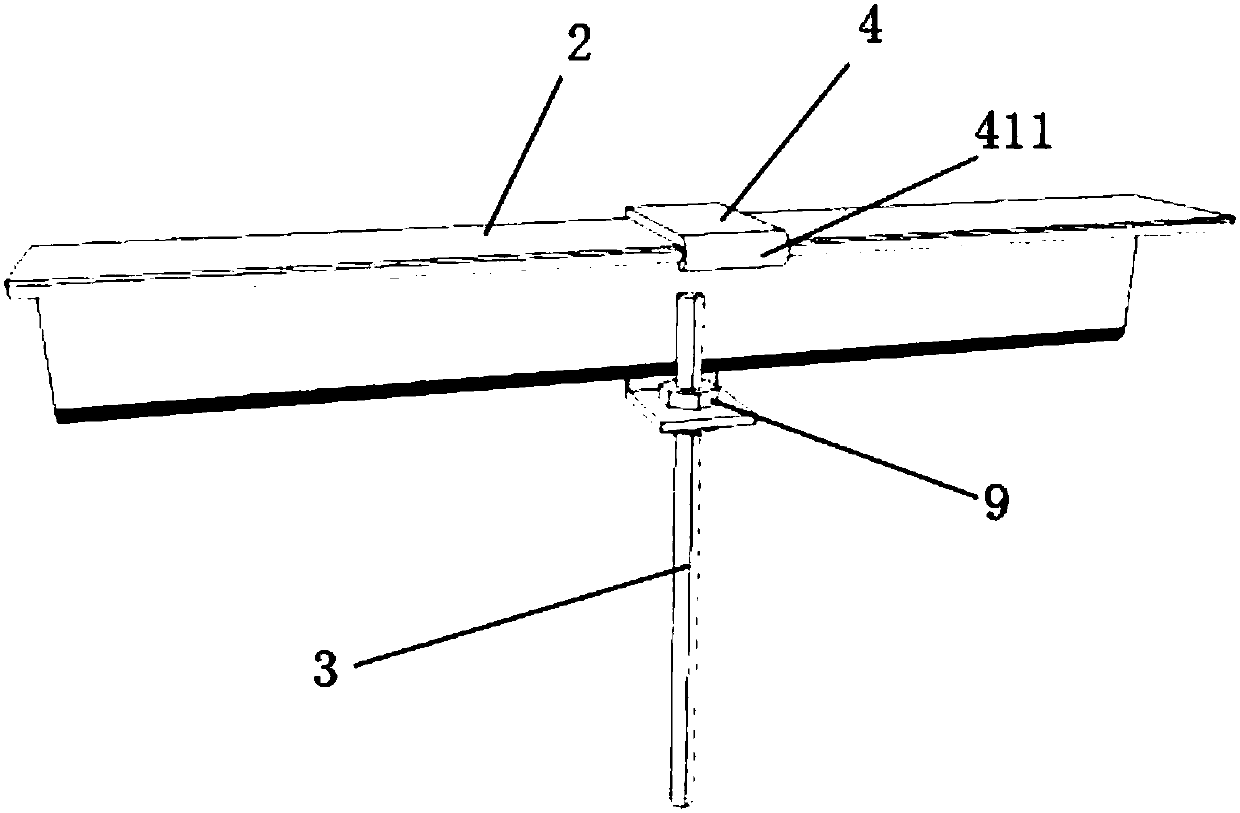

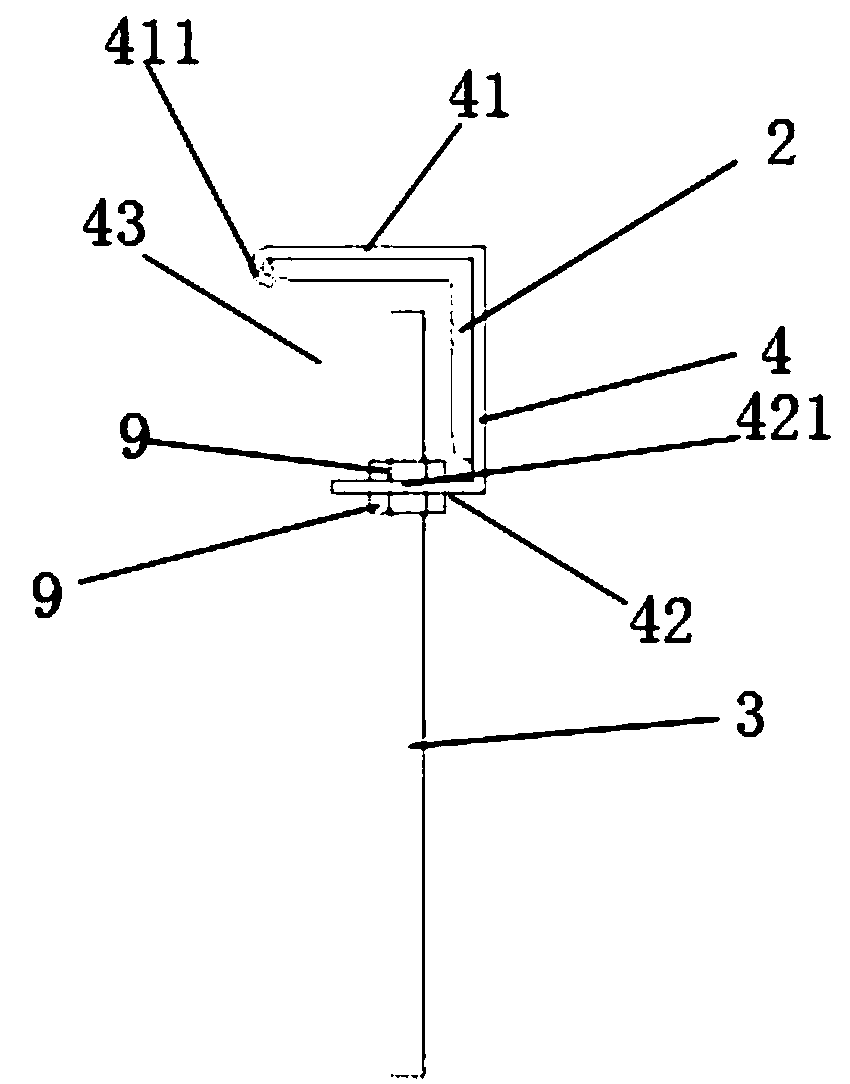

[0017] Such as Figure 1 to Figure 3 As shown, a ceiling-mounted steel frame transfer layer in this embodiment includes a transfer layer vertical bar 1, a transfer layer horizontal bar 2, a screw rod 3, a plurality of first hanging parts 4, a second hanging part 5, a clamping part 6, a main The keel 7, the auxiliary keel 8 and the fastener 9, the vertical bar 1 of the conversion layer is connected with the horizontal bar 2 of the conversion layer. The first hanger 4 is connected with the conversion layer cross bar 2, and a plurality of first hangers 4 are arranged at intervals, the screw mandrel 3 is connected with the first hanger 4 through a fastener 9, and the second hanger 5 is connected with the screw mandrel 3, The main keel 7 is installed on the second pendant 5, the aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com