Layout method of igniters in large-size scramjet

A technology of ramjet and layout method, applied in ramjet engine, engine manufacturing, machine/engine, etc., can solve the problem of inability to apply large-size ramjet combustion, and achieve the effect of increasing thrust and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: In this embodiment, the layout method of the igniter in a large-scale ramjet engine is as follows: 1. Test the effective ignition diameter of the igniter: carry out the ignition and combustion experiment of a single igniter, and determine the effective ignition of a single igniter by shooting with a high-speed camera The largest diameter D;

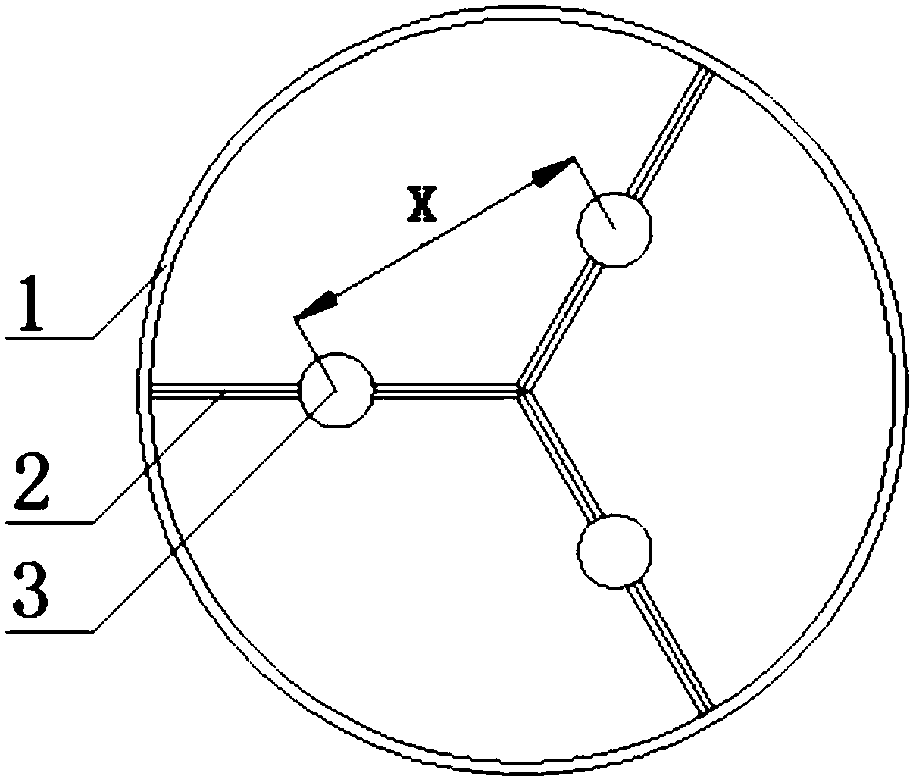

[0011] 2. Needle net layout: There are multiple igniters in the combustion chamber of the engine, and the position of the igniters is set according to the congestion ratio of less than 15%; on the cross-section of the engine, the center-to-center distance between two adjacent igniters is (0.7-1.3)D , and the three adjacent igniters are arranged in an equilateral triangle.

[0012] The value of the maximum diameter D in this embodiment is affected by factors such as the type of fuel and the working fluid of the igniter, and the value of D is also different for different types of fuel and working fluid of the i...

specific Embodiment approach 2

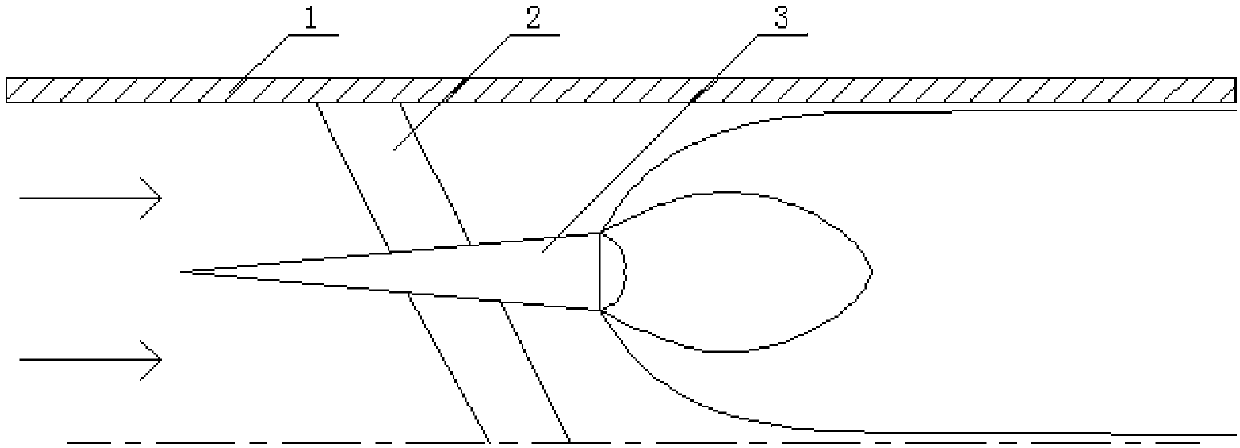

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the igniter 3 is fixed in the combustion chamber of the engine 1 through the support plate 2; the surface of the igniter 3 is uniformly provided with a plurality of first oil seepage holes; The inside of the support plate 2 is provided with a through hole, one end of the through hole is connected to the oil supply, gas supply and power supply lines on the engine, and the other end is connected to the igniter 3; the surface of the support plate 2 is evenly provided with a plurality of second oil seepage hole, the second oil seepage hole communicates with the through hole inside the support plate 2. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the horizontal central axis of the igniter is parallel to the horizontal central axis of the engine. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com