Deep hole diameter and depth detection tool

A technology of depth detection and deep hole, applied in the direction of mechanical diameter measurement, mechanical depth measurement, etc., to achieve the effect of wide measurement range, accurate data and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

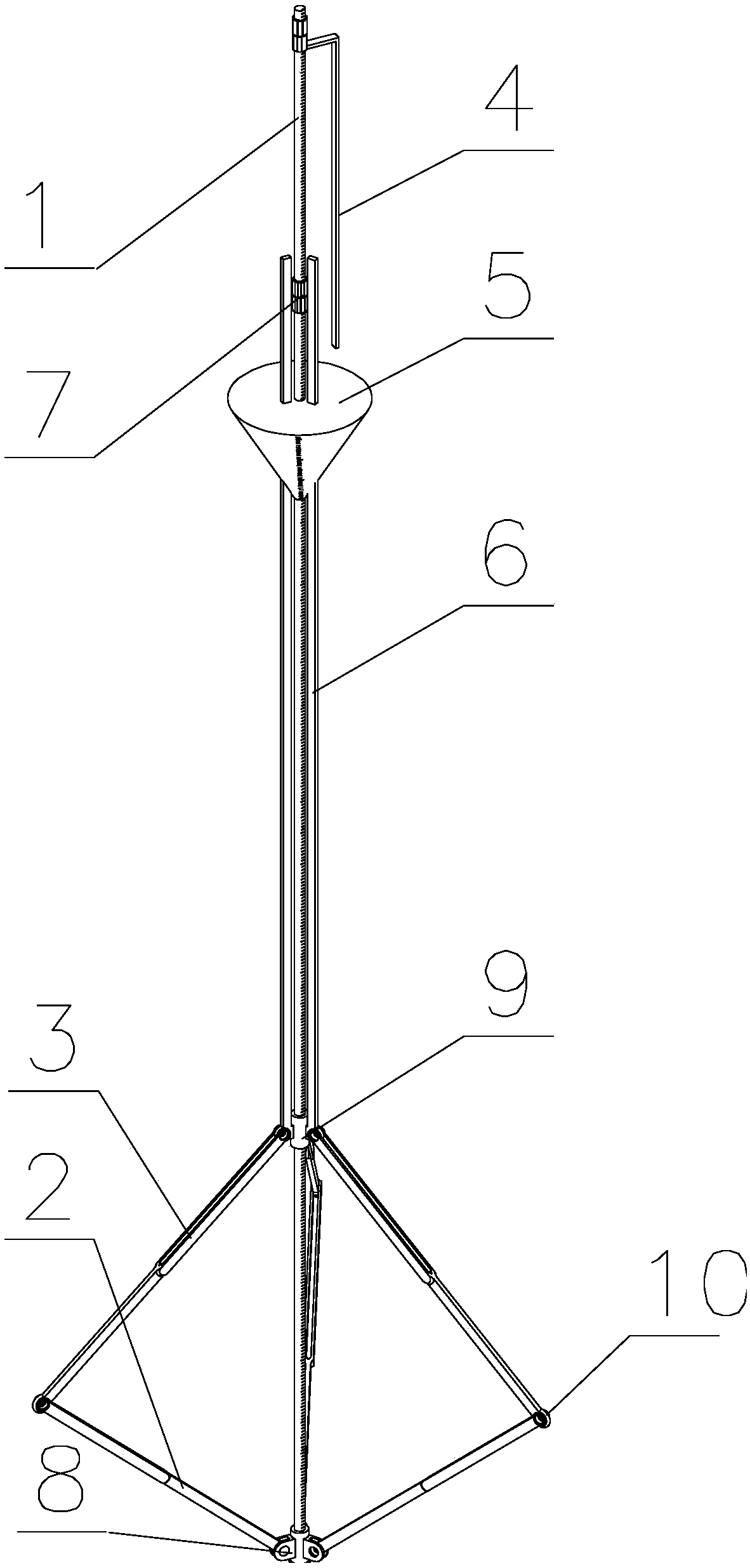

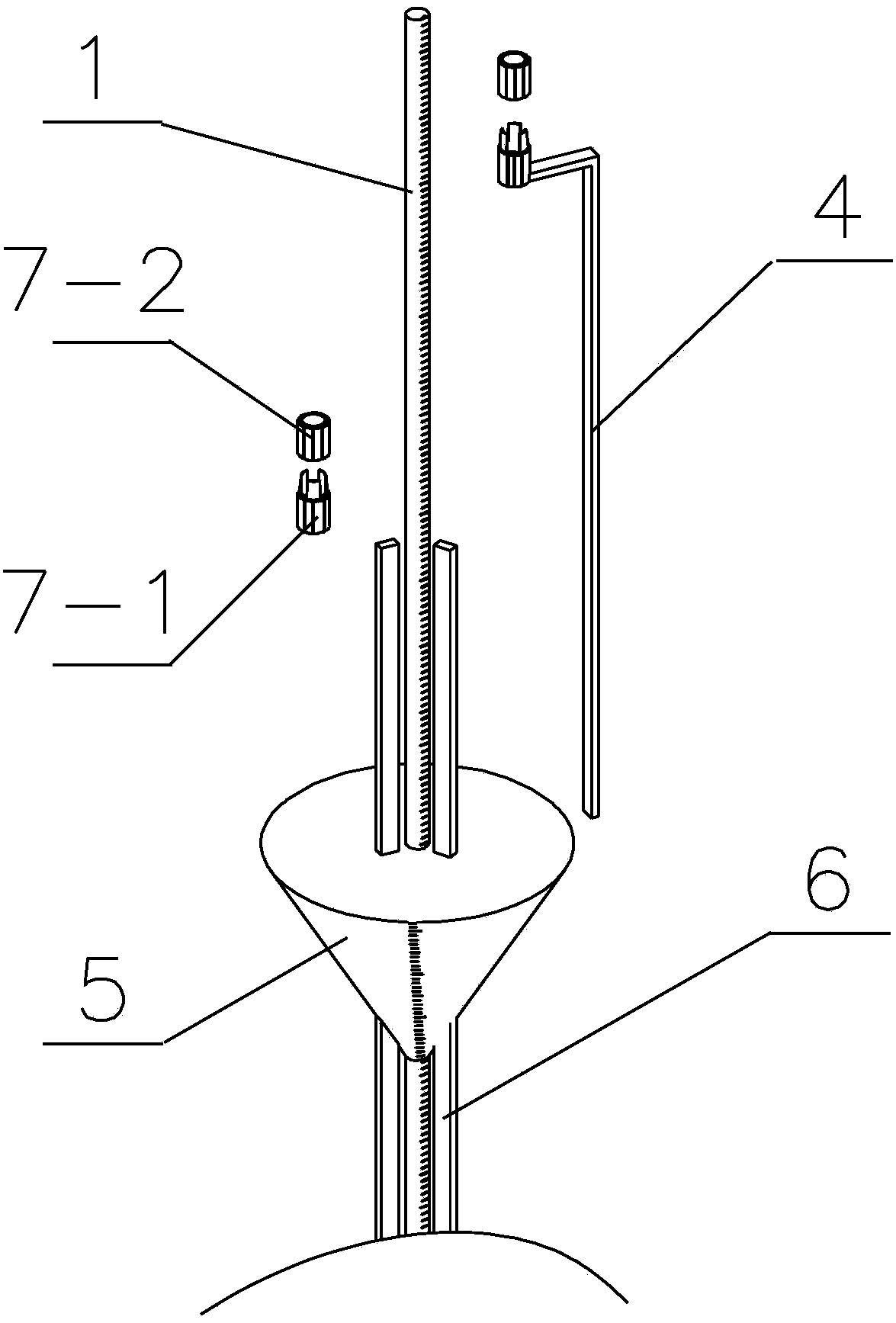

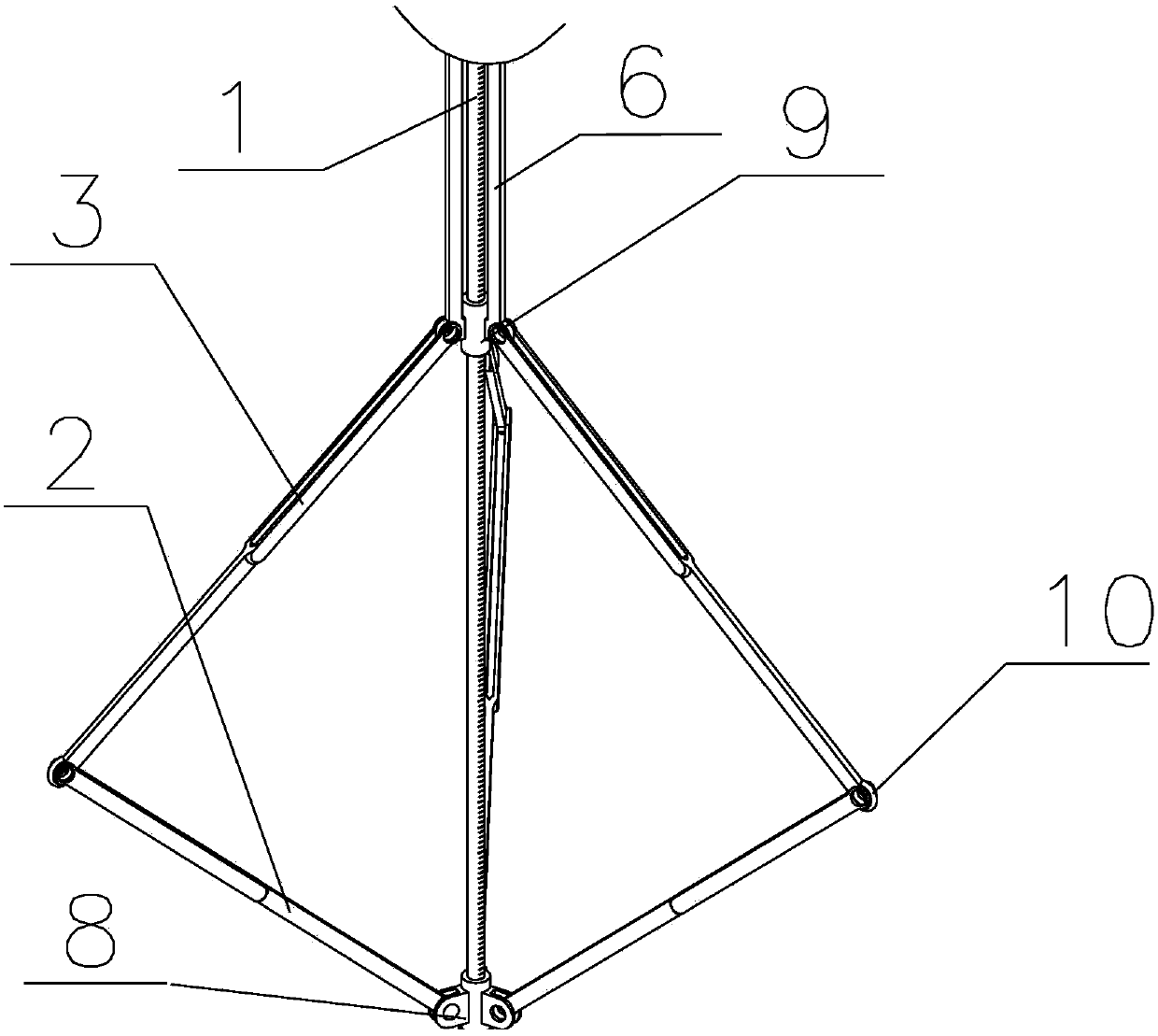

[0020] Such as Figure 1~5 Shown, a kind of deep hole diameter and depth detection tool, comprise central rod 1, some lower measuring rods 2 of equal length and some upper measuring rods 3 of equal length, the length of described upper measuring rod 3 and described lower measuring rod 2 Equal, one end of the lower measuring rod 2 is hinged to the bottom of the central rod 1, the other end is hinged to one end of the upper measuring rod 3, and the other end of the upper measuring rod 3 is slidably arranged on the central rod 1 On the top, the plane formed by the axis of the lower measuring rod 2 and the axis of the upper measuring rod 3 passes through the axis of the central rod 1, and the central rod 1 is provided with a diameter scale parallel to the central rod 1 4 and a positioning cone 5, the positioning cone 5 is located between the diameter scale 4 and the upper measuring rod 3, and is coaxial with the central rod 1, and the upper measuring rod 3 and the central rod 1 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com