Online operation and maintenance method and system for secondary equipment in intelligent substation based on visual display

A technology for smart substations and secondary equipment, applied in transmission systems, digital transmission systems, information technology support systems, etc., can solve the problems of less research on the operation sequence control of protection devices, error-prone, and low work efficiency, and achieve shortening The effect of reducing manual operation time, reducing the risk of misoperation, and improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is described in detail below in conjunction with accompanying drawing:

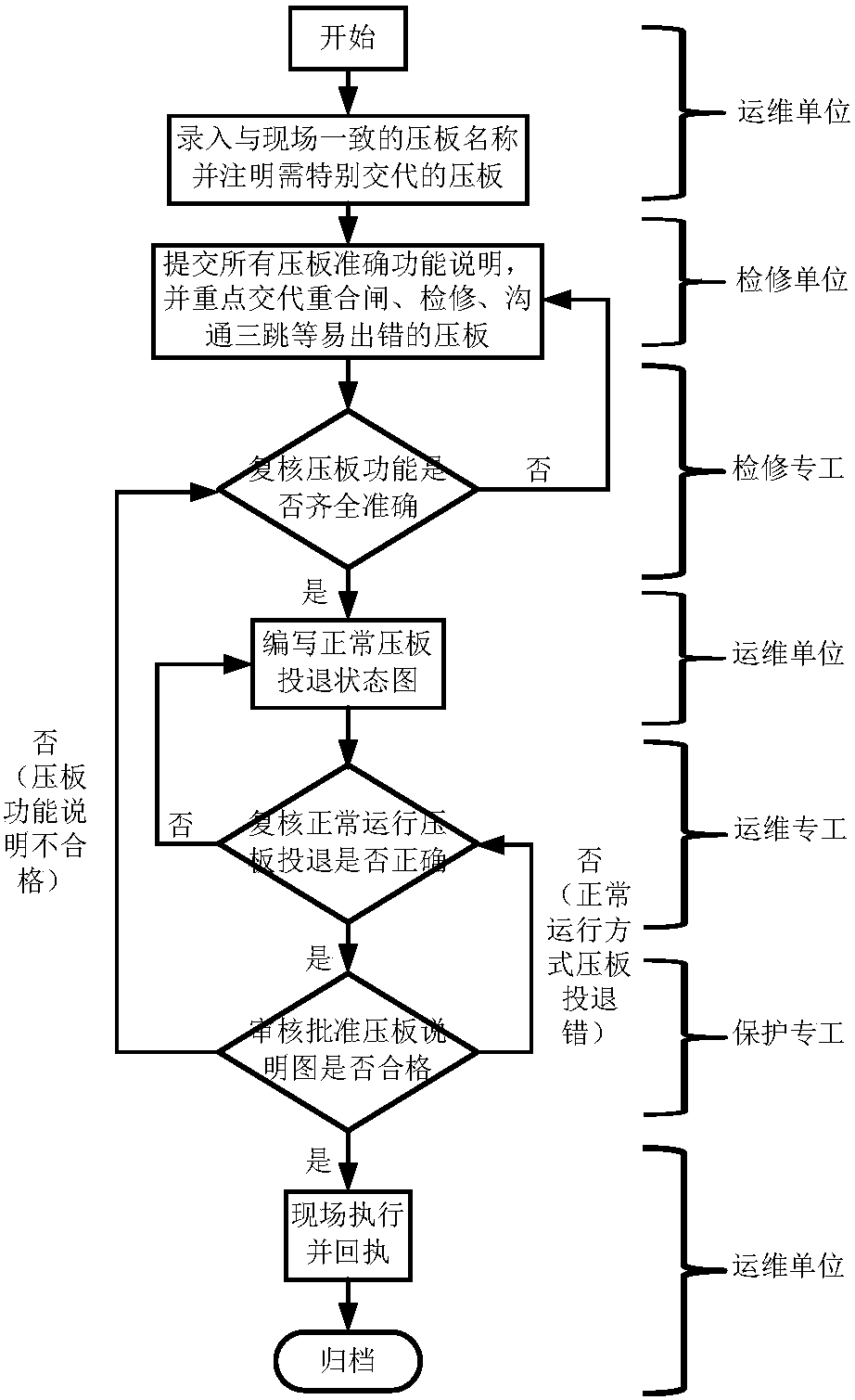

[0069] The invention discloses an online operation and maintenance method for secondary equipment of an intelligent substation based on visual display, including:

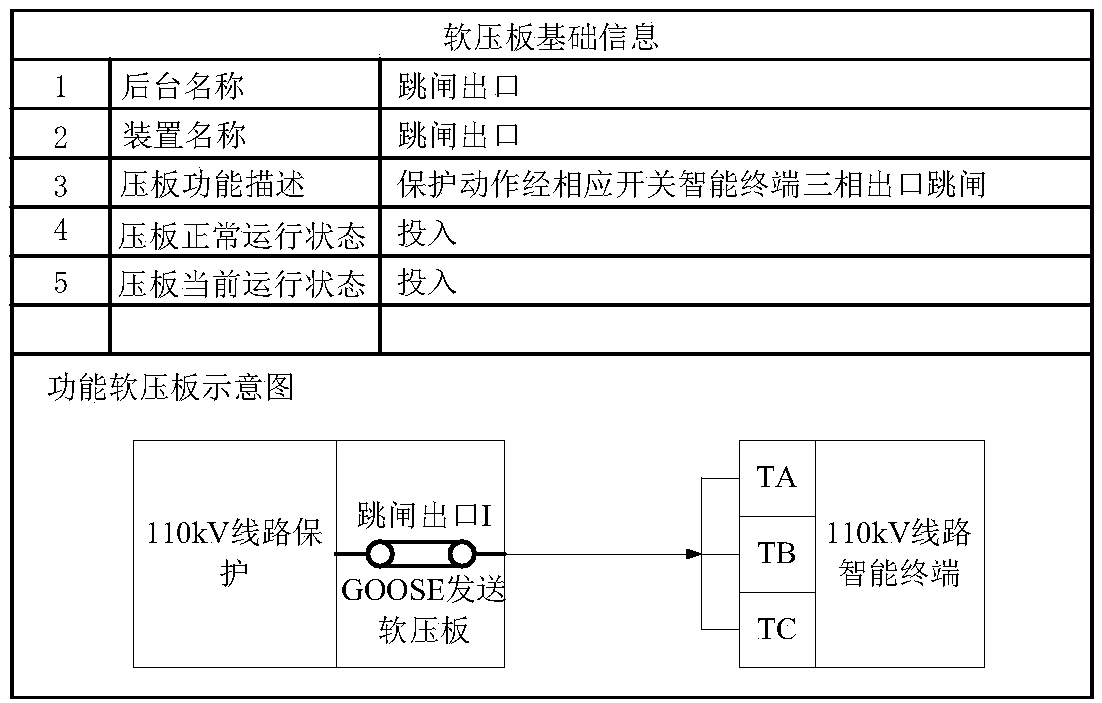

[0070] (1) Unify the naming and definition of the soft pressure plate of the secondary equipment of the smart substation according to the standard rules, and standardize the design of the soft pressure plate;

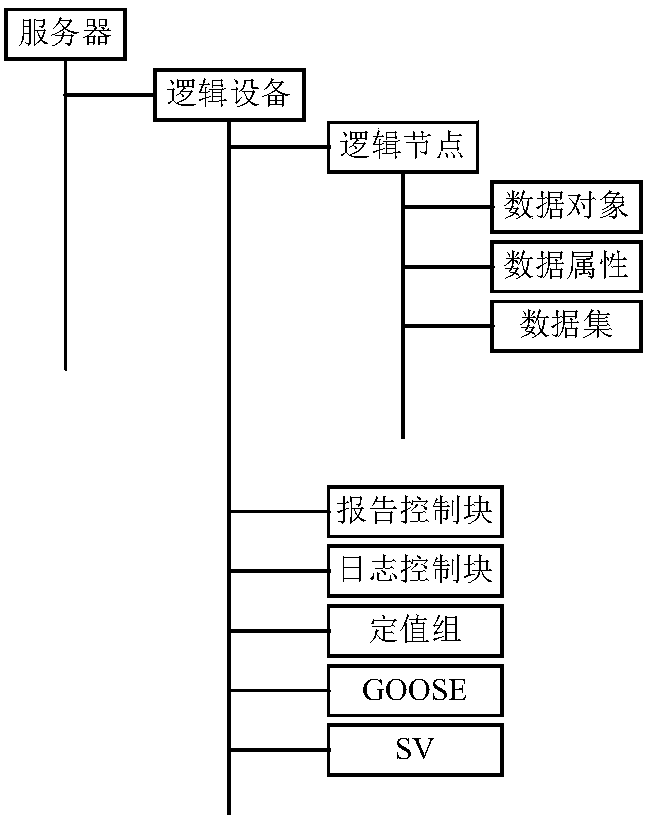

[0071] (2) Review the function description of the soft pressure plate and the throw-in and withdrawal status of the normal operation mode of the secondary equipment of the smart substation, and enter the function description of the soft press plate and the throw-in and withdrawal status of the normal operation mode after the review into the background monitoring system;

[0072] (3) Regular automatic inspection or manual inspection of the soft pressing plate in the whole station, and intelligent alarm for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com