Case fixing device

A technology for fixing devices and casings, which is applied in the direction of electromechanical devices, casings/covers/supports, magnetic circuit shapes/styles/structures, etc., and can solve the problem of loose fit between magnetic tiles and casings, lack of stable positioning devices, Fix the inaccurate position and other problems to achieve the effect of high equipment flexibility, good positioning stability and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

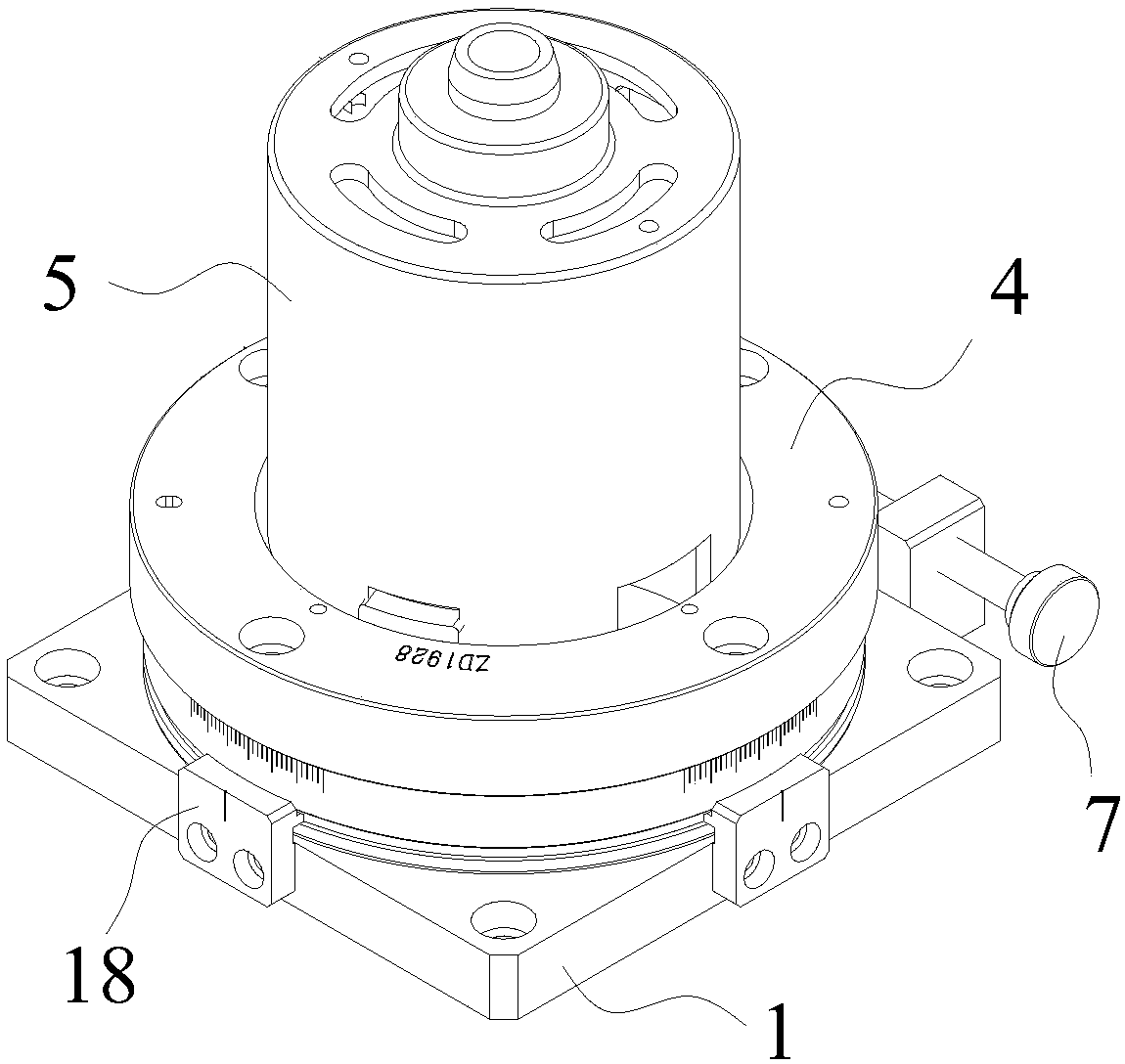

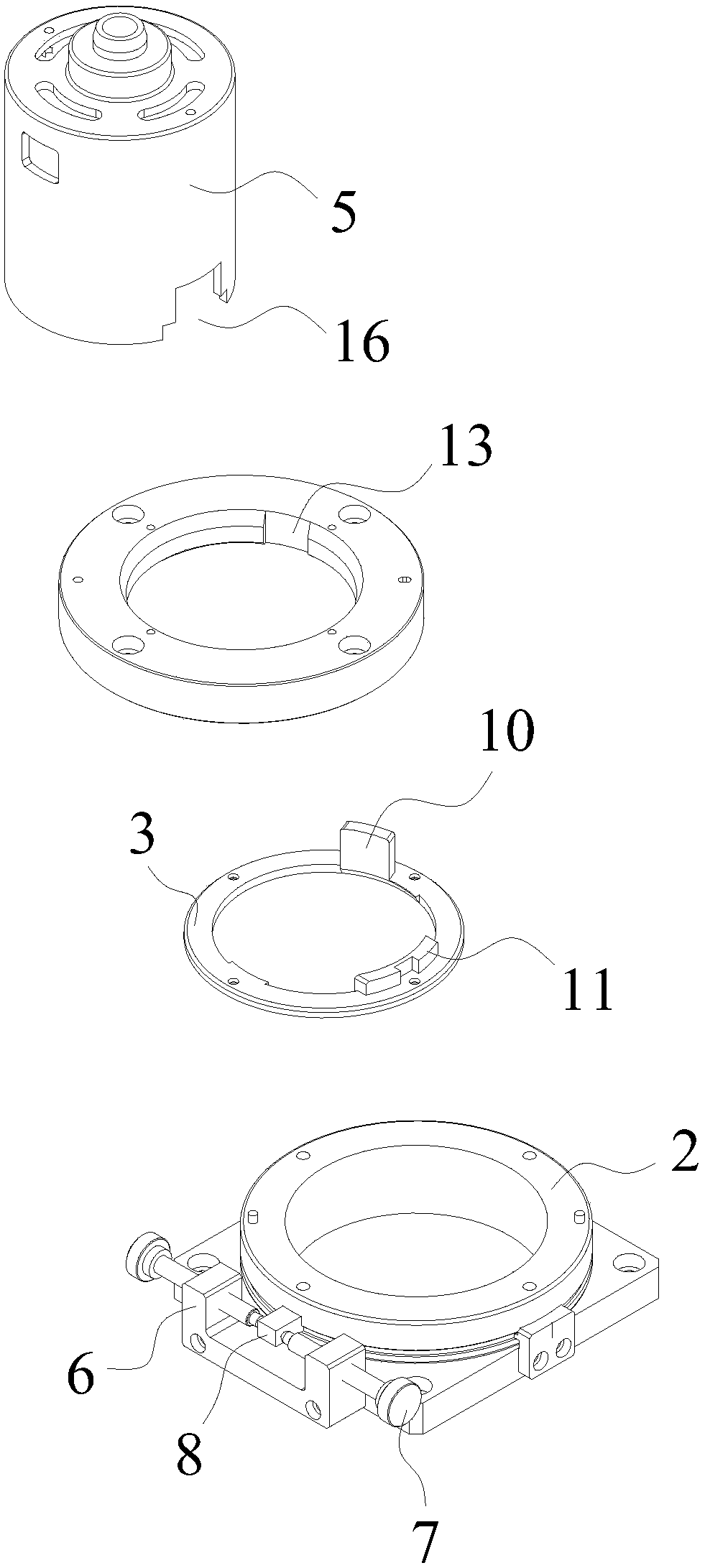

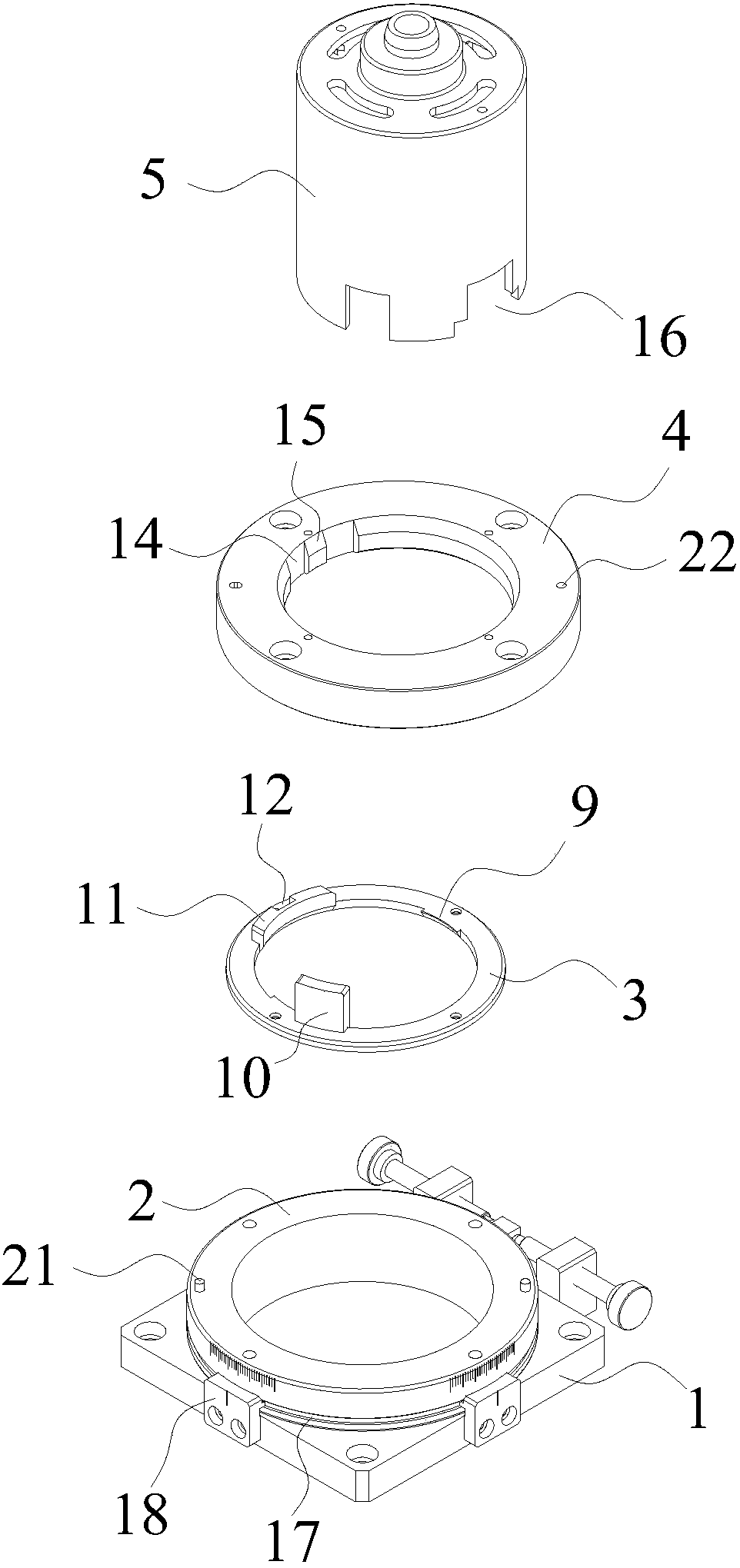

[0024] As shown in the figure, this embodiment discloses a casing fixing device, which includes a positioning disc base 1, and the positioning disc base 1 is provided with an annular fine-tuning rotating ring 2 that can rotate along its own center on the positioning disc base 1, An annular positioning ring 3 is fixed on the upper surface of the fine-tuning rotating ring 2, and an annular locking ring 4 is clipped and fixed on the positioning ring 3, and the inner ring of the locking ring 4 is clipped and fixed to the casing 5.

[0025] The sidewall edge of positioning disc base 1 is provided with U-shaped rotating support seat 6, and two vertical sides of U-shaped rotating support seat 6 are provided with two relative fixed knobs 7, and the distance between the fixed knobs 7 can be adjusted. Adjustment, a fixed ear 8 is sandwiched between the two fixed knobs 7, and one end of the fixed ear 8 is fixed on the side wall of the fine-tuning rotary ring 2.

[0026] The inner edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com