Patents

Literature

32results about How to "Suitable for large-scale automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

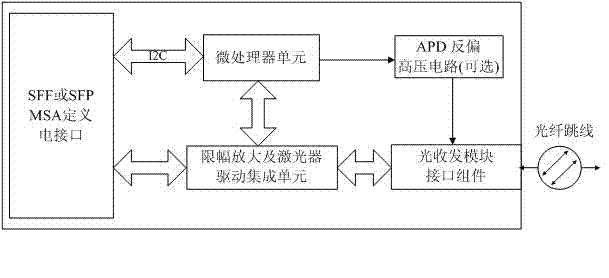

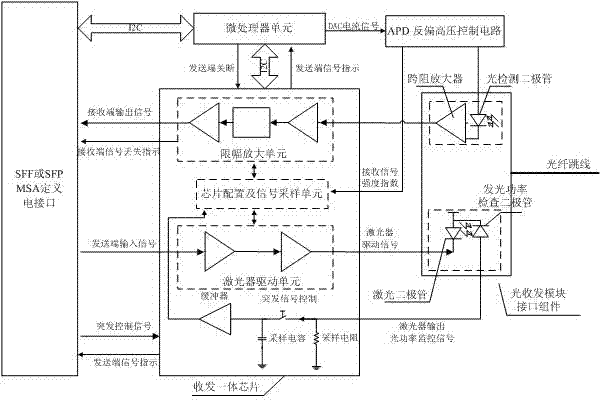

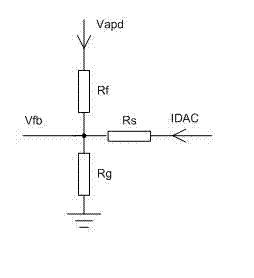

Optical network unit for passive optical network and signal processing method thereof

InactiveCN102255656ASimple structureLow costFibre transmissionElectromagnetic transceiversSmall form factorHigh pressure

The invention relates to the field of optical fiber communication and discloses an optical network unit for a passive optical network. The optical network unit comprises an electric interface meeting SFF (Small Form-factor Pluggable) or SFPMSA (Small Form-factor Pluggable Transceiver Multi-Source Agreement) definition, a microprocessor unit, an integrated transceiver chip and an optical transceiver module interface component, wherein the electric interface is respectively connected to the microprocessor unit and the integrated transceiver chip; the microprocessor unit is connected to the integrated transceiver chip; and the integrated transceiver chip is connected to the optical transceiver module interface component. The invention also discloses a signal processing method of the optical network unit for the passive optical network. A limiting amplifier unit, a laser driving unit, a chip and a signal acquiring unit are integrated in the integrated transceiver chip. The integrated transceiver chip, the microprocessor unit and a high-pressure circuit converting chip are matched with each other, thereby forming the optical network unit. The optical network unit designed according to the scheme has the characteristics of simple structure, high integrated level, low cost, suitability for large-scale automatic production, and the like.

Owner:成都新易盛通信技术股份有限公司

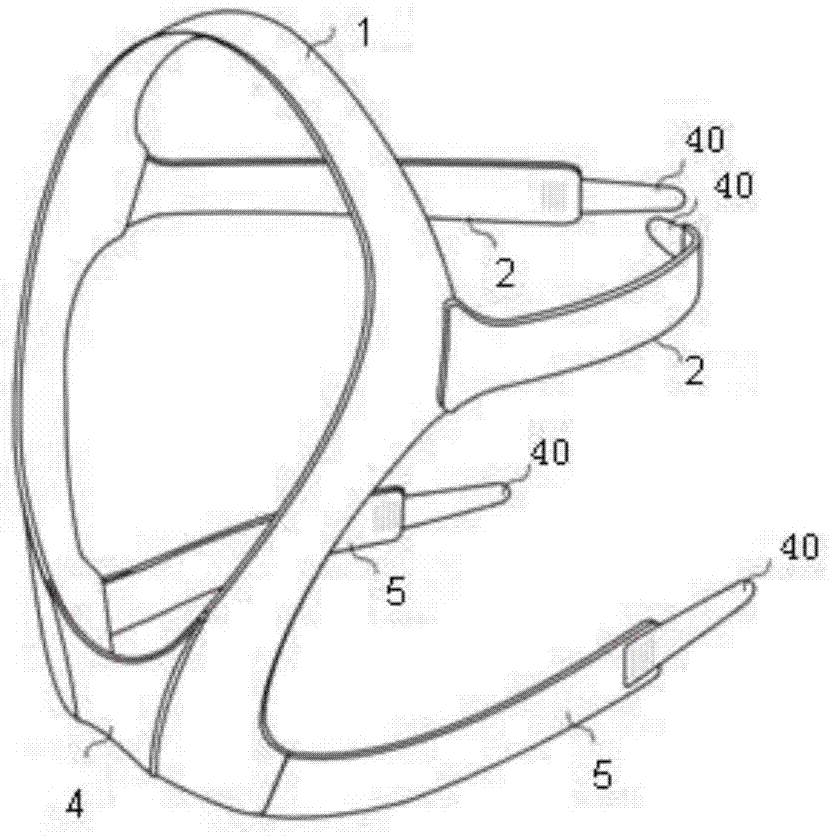

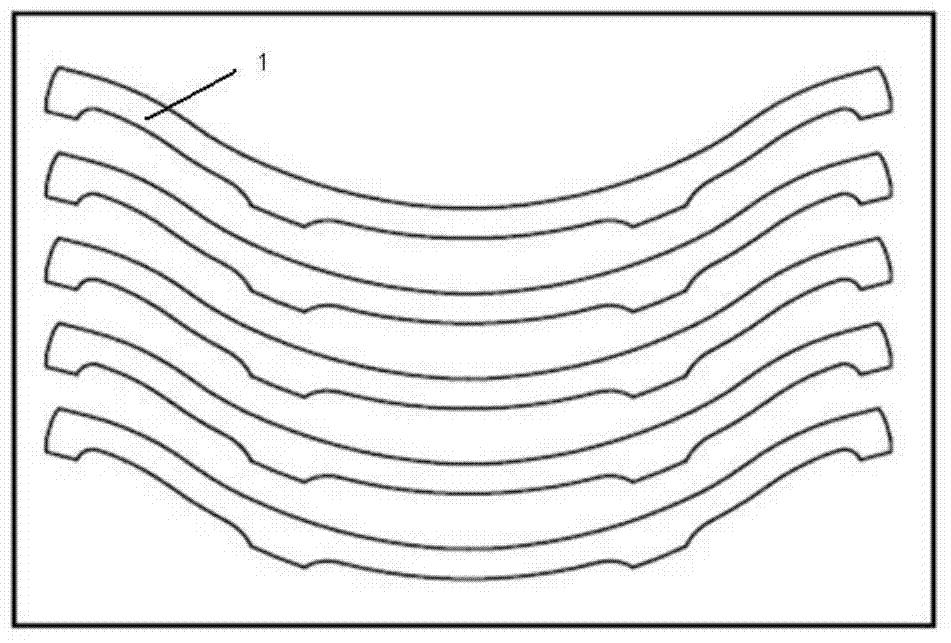

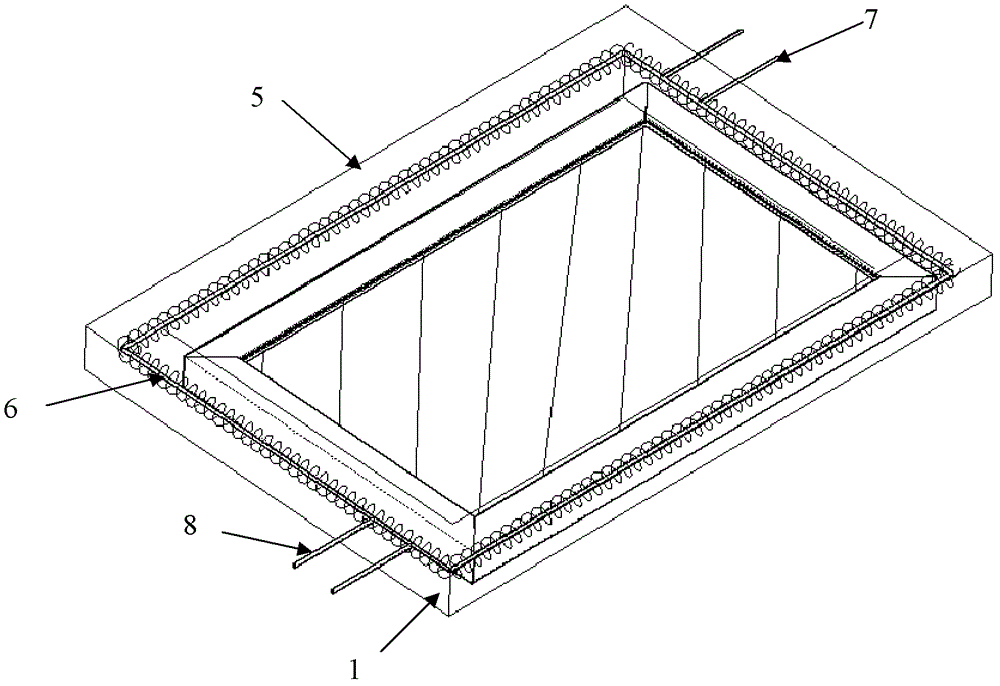

Breathing mask three-dimensional head tying band, main tying band composing breathing mask three-dimensional head tying band and processing methods of breathing mask three-dimensional head tying band and main tying band

InactiveCN104225751AEven by forceWear safeRespiratory masksBreathing masksBiomedical engineeringMedical treatment

The invention provides a breathing mask three-dimensional head tying band, a main tying band composing the breathing mask three-dimensional head tying band and processing methods of the main tying band and the breathing mask three-dimensional head tying band, and relates to a head tying band for a medical treatment breathing machine mask, a major component composing the head tying band and machine methods of the head tying band and the major component, in particular to the three-dimensional head tying band, the main tying band composing the three-dimensional head tying band and the processing methods of the three-dimensional head tying band and the main tying band. Most components of both the three-dimensional head tying band and the main tying band are formed by connecting straight-strip parts; the straight-strip parts are high in universality and easy and flexible to assemble, the assembly angle can be adjusted at will so that the main tying band and the three-dimensional head tying band comprising the main tying band can be better attached to the head, stress is more even, and the main tying band and the three-dimensional head tying band are more comfortable to wear. The processing methods of the main tying band and the three-dimensional head tying band are simple, gapless discharge can be realized, the cost can be reduced, the components are assembled flexibly and diversely, and therefore different requirements of a user can be met.

Owner:RESGOOD MEDICAL CO LTD

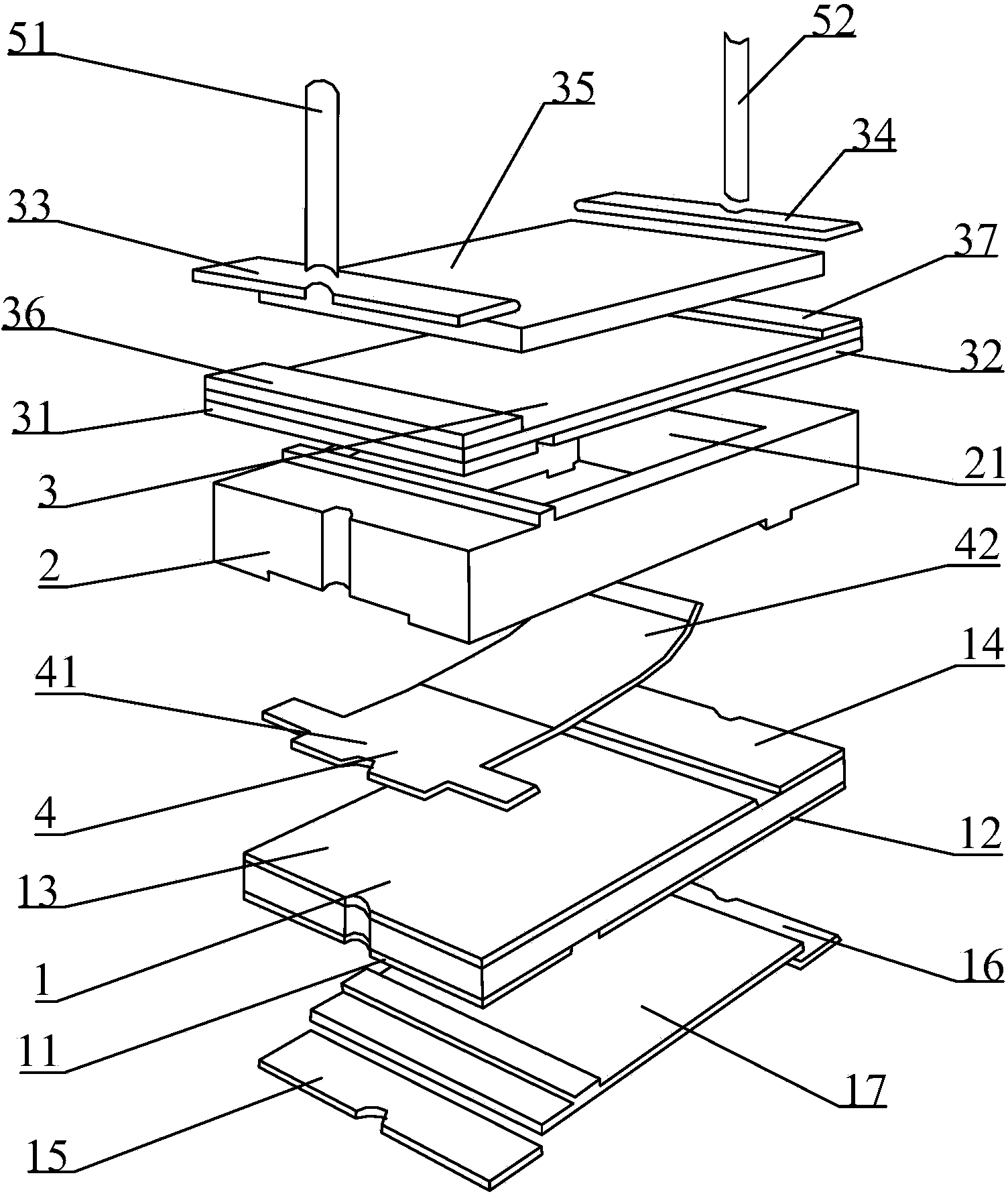

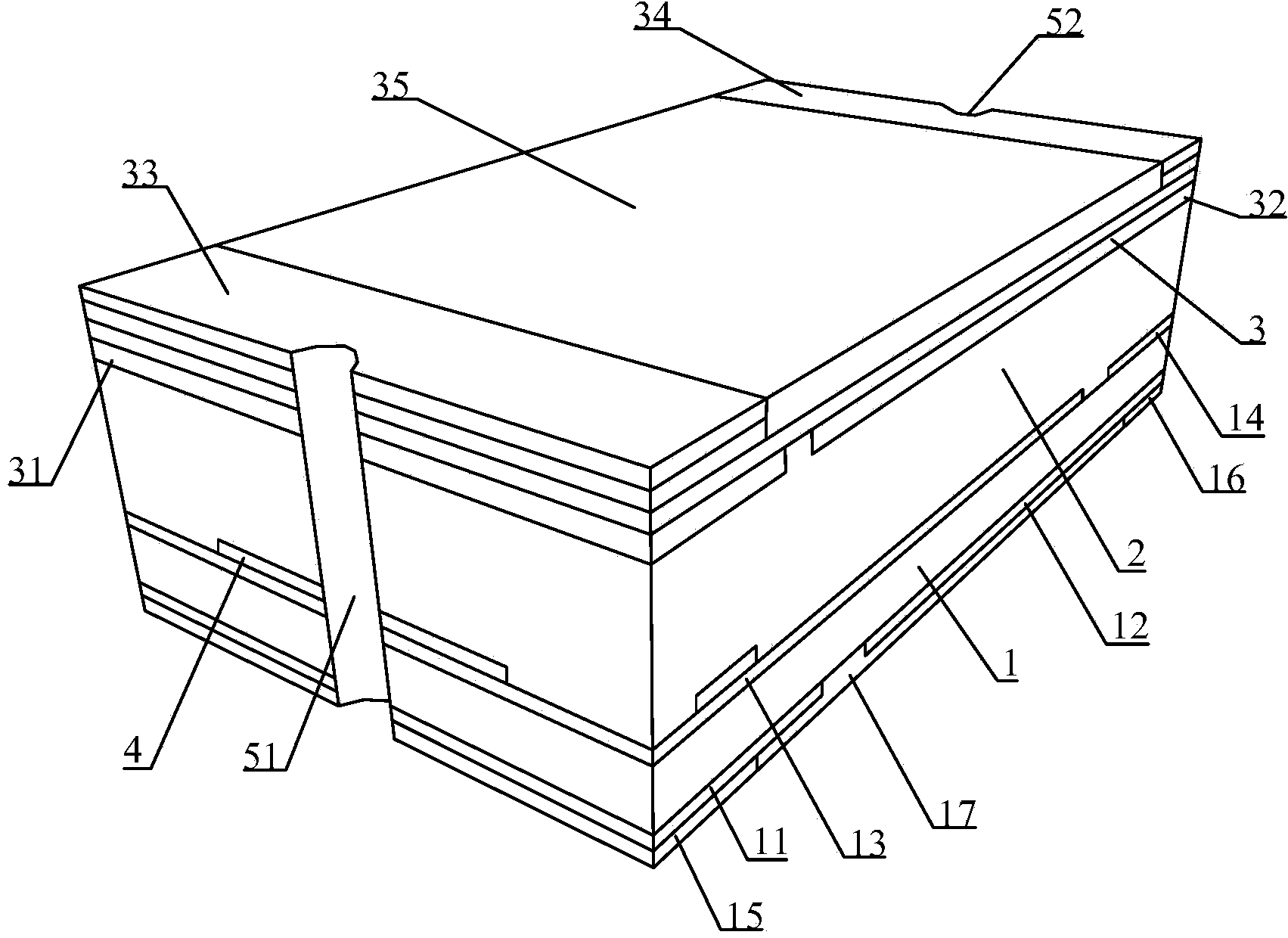

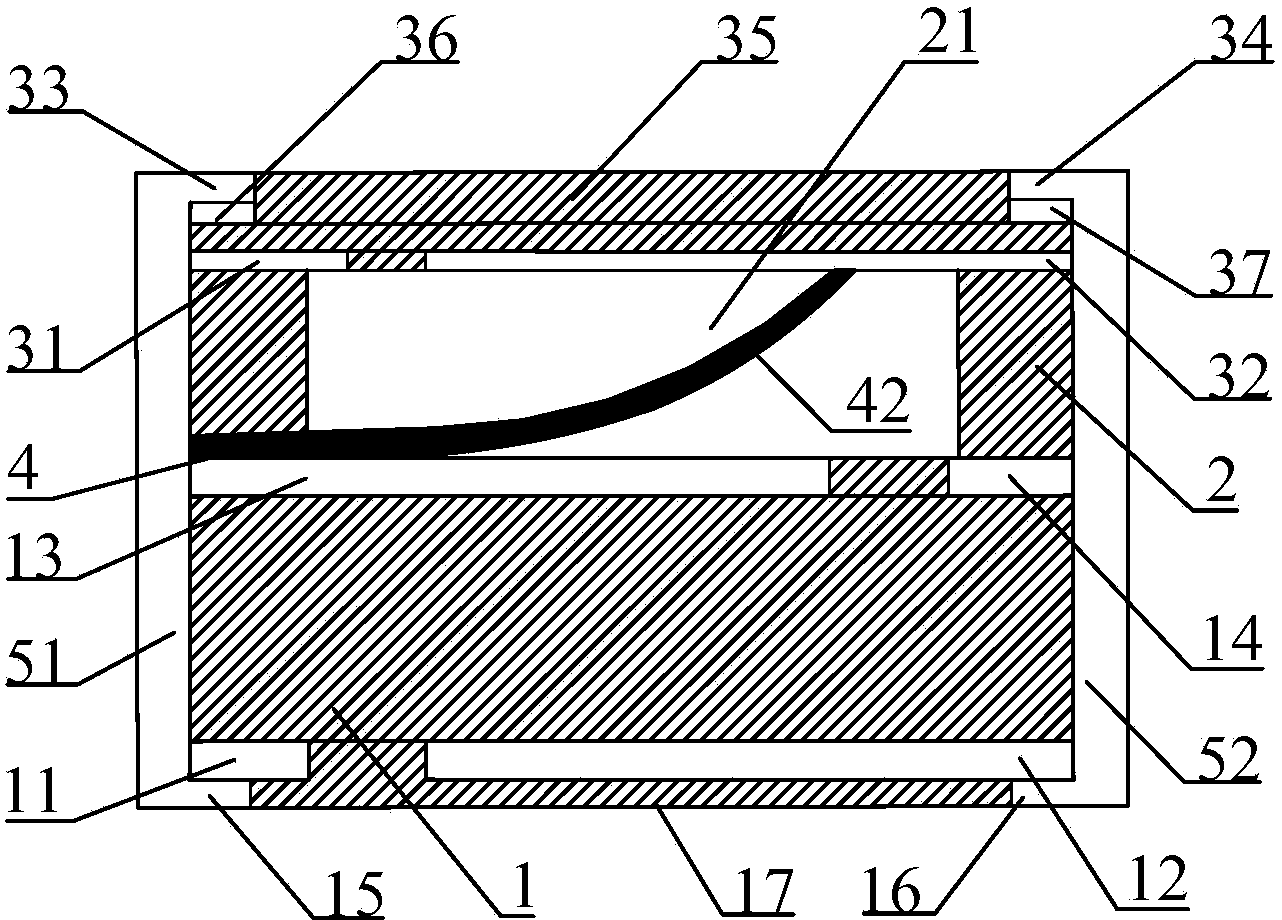

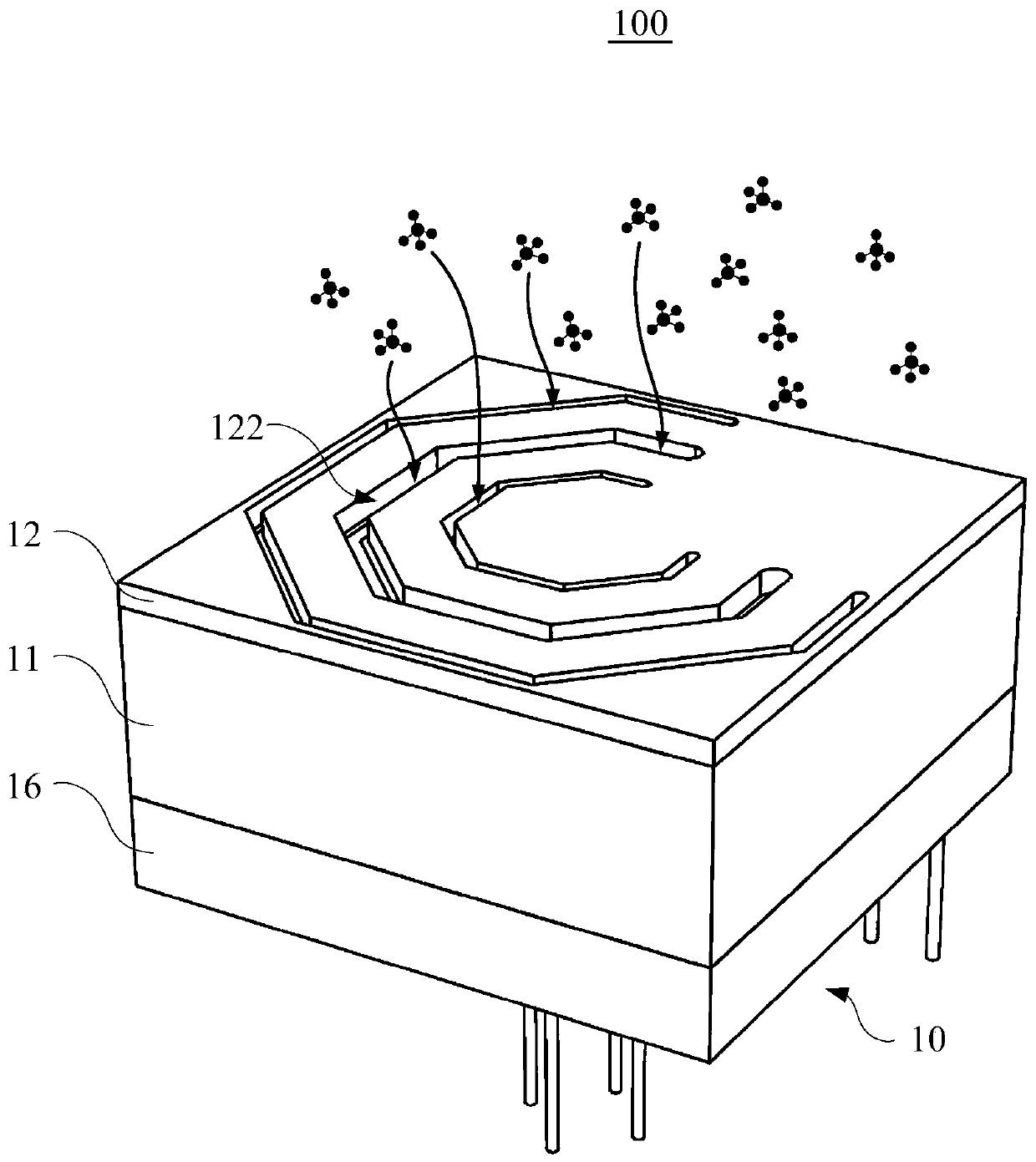

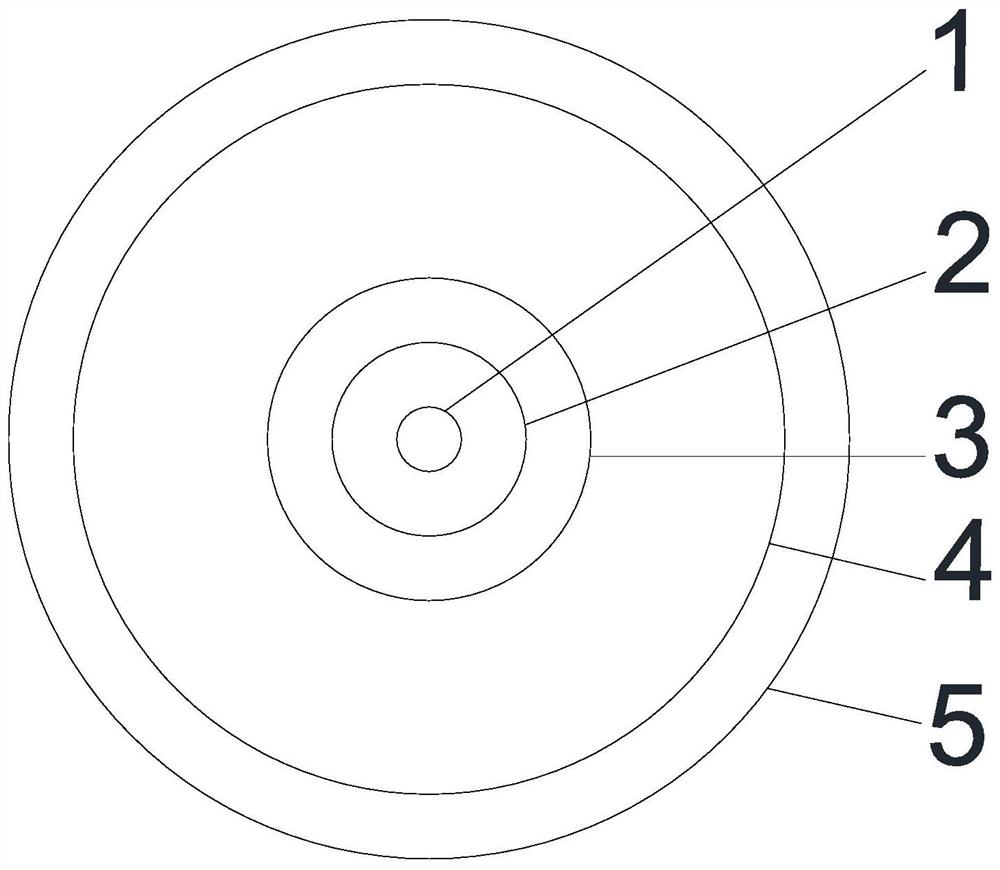

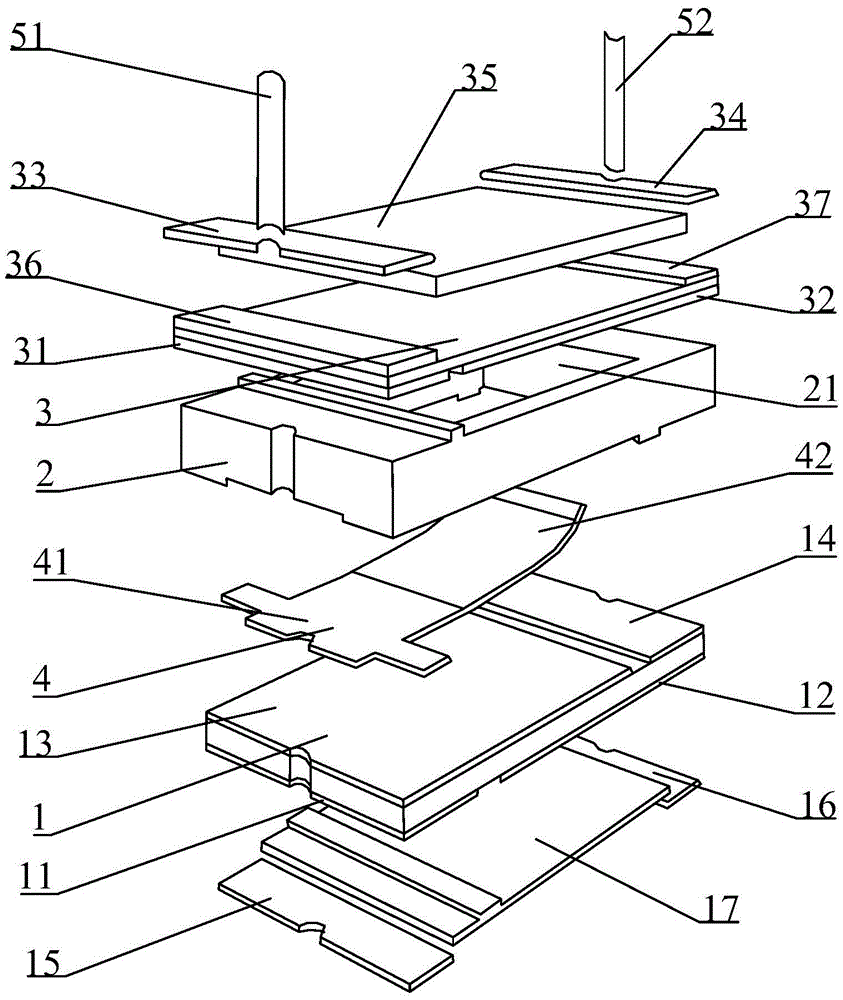

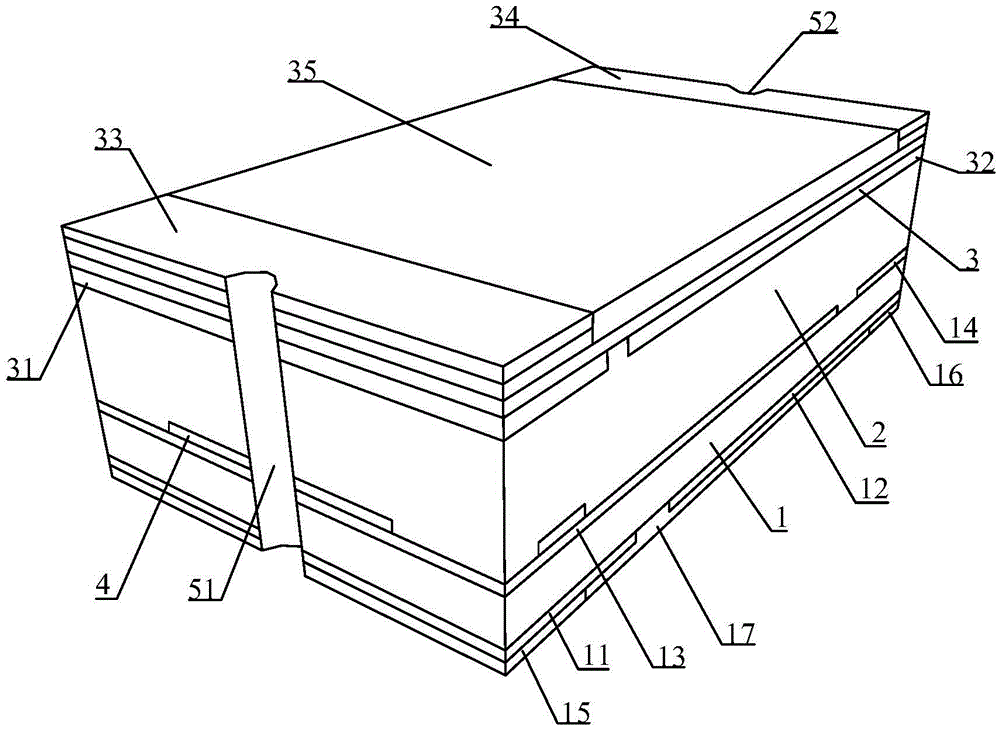

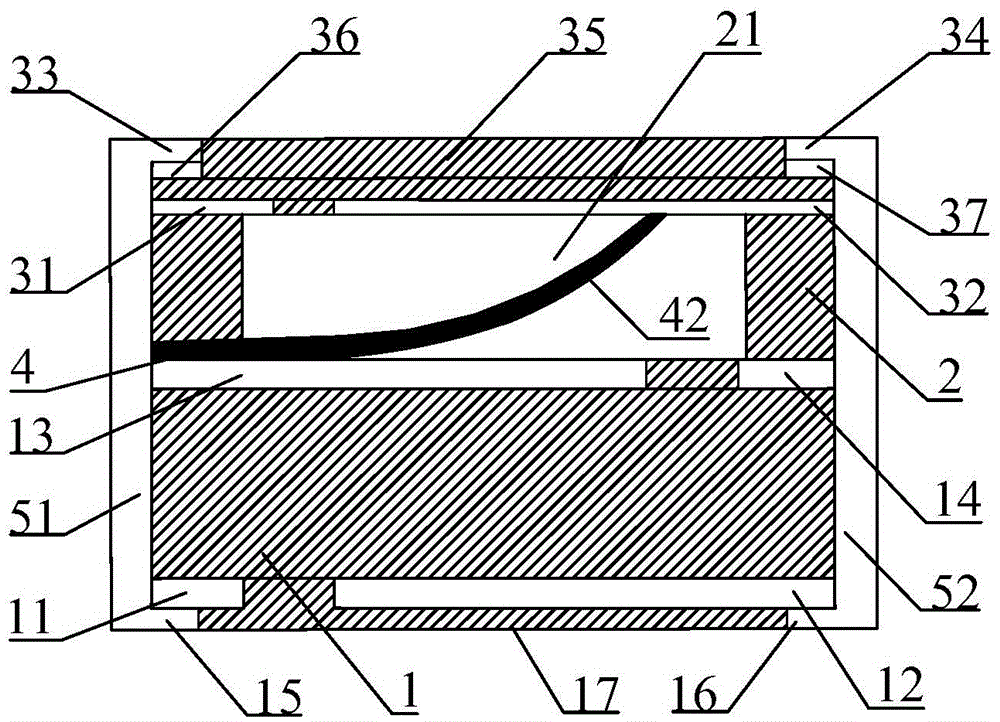

Thermoelectric protection element and manufacturing method thereof

ActiveCN104112626ASimple structureSuitable for large-scale automated productionThermal switch detailsIntegrated circuitEngineering

The invention discloses a thermoelectric protection element and a manufacturing method thereof. The thermoelectric protection element comprises a heating element, an insulated shell and an upper cover plate sequentially stacked from the bottom top, wherein the bottom surface of the heating element is provided with a first left electrode and a first right electrode; the top surface of the heating element is provided with a second left electrode and a second right electrode; the bottom surface of the upper cover plate is provided with a third left electrode and a third right electrode; the insulated shell is internally provided with a first cavity; the fixed end of a thermal drive switch is clamped between the bottom surface of the insulated shell and the second left electrode; and the moving end of the thermal drive switch is located inside the cavity of the insulated shell and is electrically contacted with the third right electrode in a normal state. The thermoelectric protection element also comprises a first left pad, a first right pad, a second left pad, a second right pad, a left-end electrode and a right-end electrode. According to the thermoelectric protection element, the structure is simple, large-scale automatic production is facilitated, the manufacturing cost is low, the element area is small, space is saved, and the thermoelectric protection element can be applied to the integrated circuit surface-mount technology.

Owner:上海神沃电子有限公司

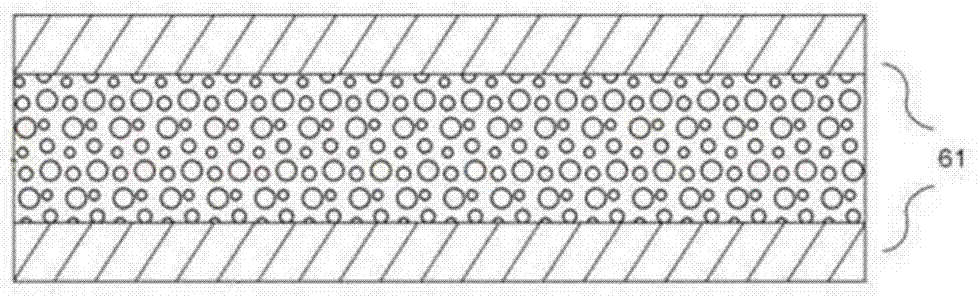

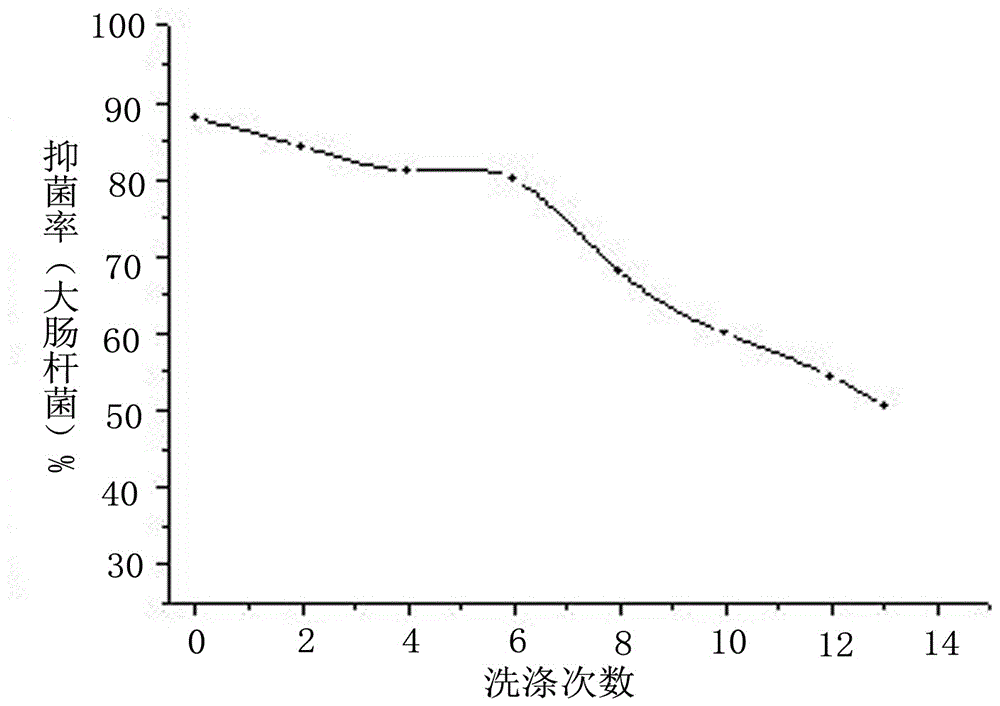

Preparation method of antibacterial wool flocculus

InactiveCN106400472ABreathableImprove dehumidification effectCarbon fibresBiochemical fibre treatmentReducerCell metabolism

The invention provides a preparation method of antibacterial wool flocculus. The preparation method mainly comprises the following steps: supplying a kind of wool flocculus, a nanometer silver dispersed solution and a reducer; and impregnating the wool flocculus in the nanometer silver solution to carry out impregnation reduction, and then carrying out press-rolling and drying treatment to obtain the antibacterial wool flocculus. The preparation method is simple and feasible and is suitable for automation production in a large scale. Meanwhile, a product prepared by the preparation method has the characteristics of air permeability, strong moisture exhaust performance and capabilities of promoting sleep and cell metabolism, enhancing vitality, delaying aging and inhibiting germs, and can effectively prevent various skin lesions and pruritus.

Owner:HENAN INST OF ENG

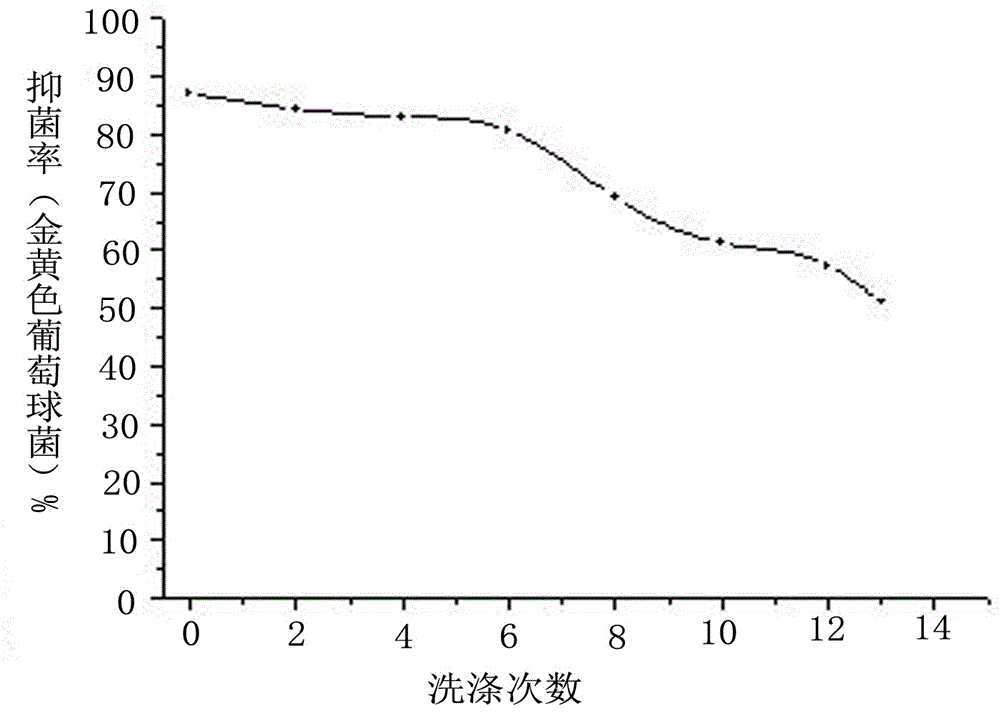

Device and method for marinating eggs

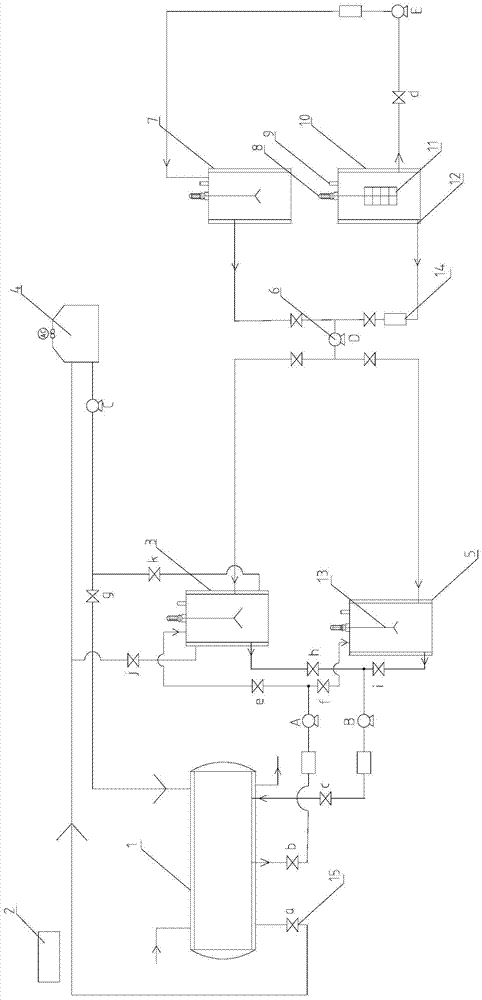

The invention relates to a device for marinating eggs, comprising an egg marinating pot, a hot marinating soup storage pot, a cold marinating soup storage pot, a cooling column and a spice cooking pot. The spice cooking pot for making marinating soup is connected with the hot marinating soup storage pot and the cold marinating soup storage pot, respectively; the hot marinating soup storage pot and the cold marinating soup storage pot are connected with the egg marinating pot, respectively; and the cooling column for cooling is connected with the cold marinating soup storage pot and an egg cooking pot, respectively. The invention also relates to a method for marinating eggs with hot marinating soup and cold marinating soup alternately. The device and method for marinating eggs disclosed in the invention have the advantages of time saving, quick absorption of marinating soup by eggs and high automation degree, are especially suitable for automatic production in large scale, and belong to the technical field of marinating egg processing.

Owner:广东无穷食品集团有限公司

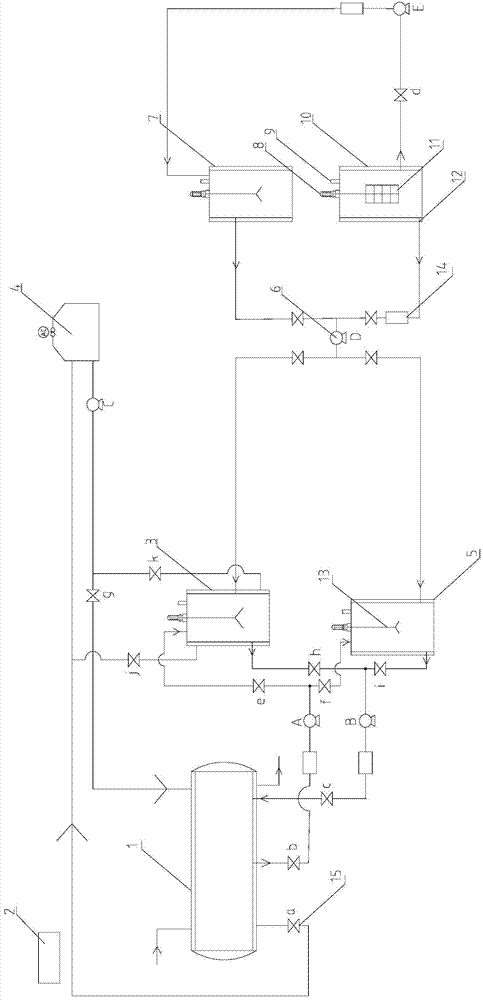

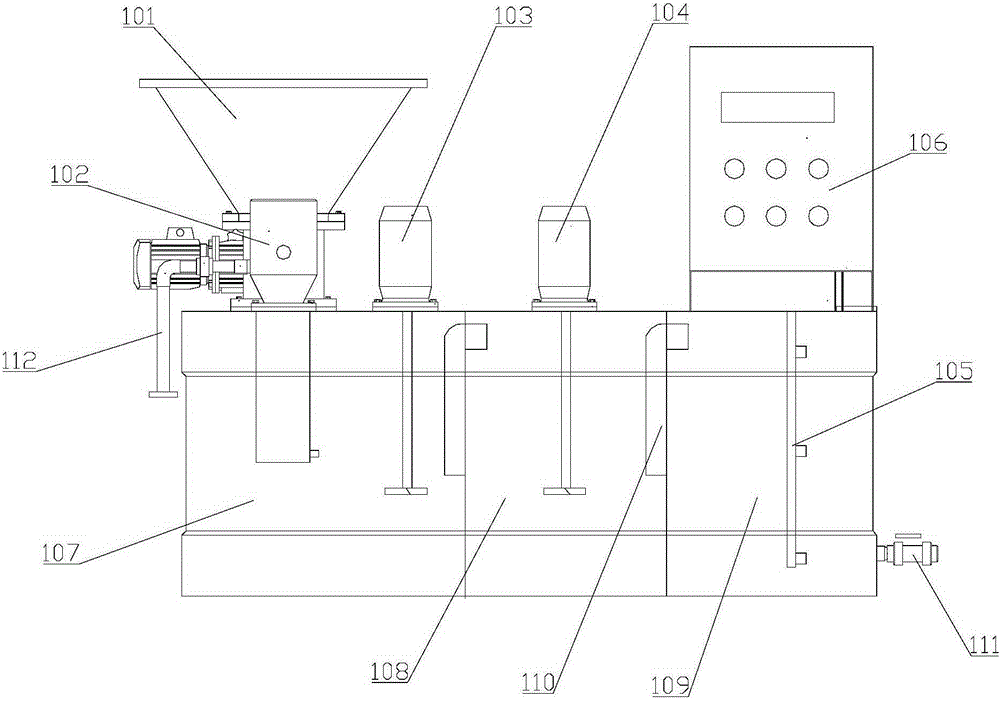

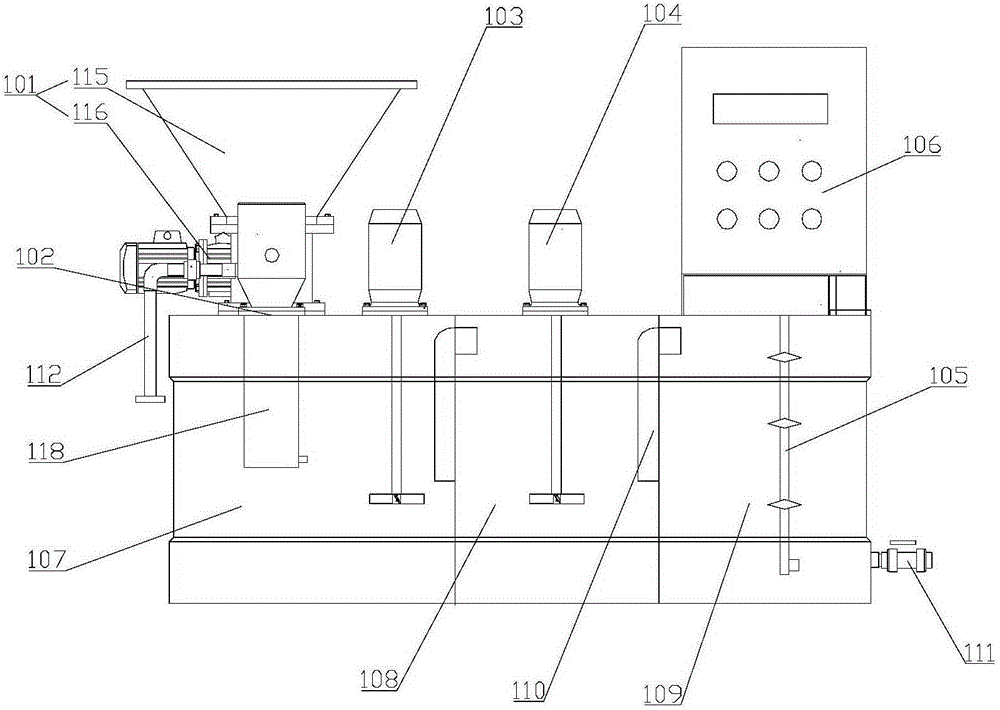

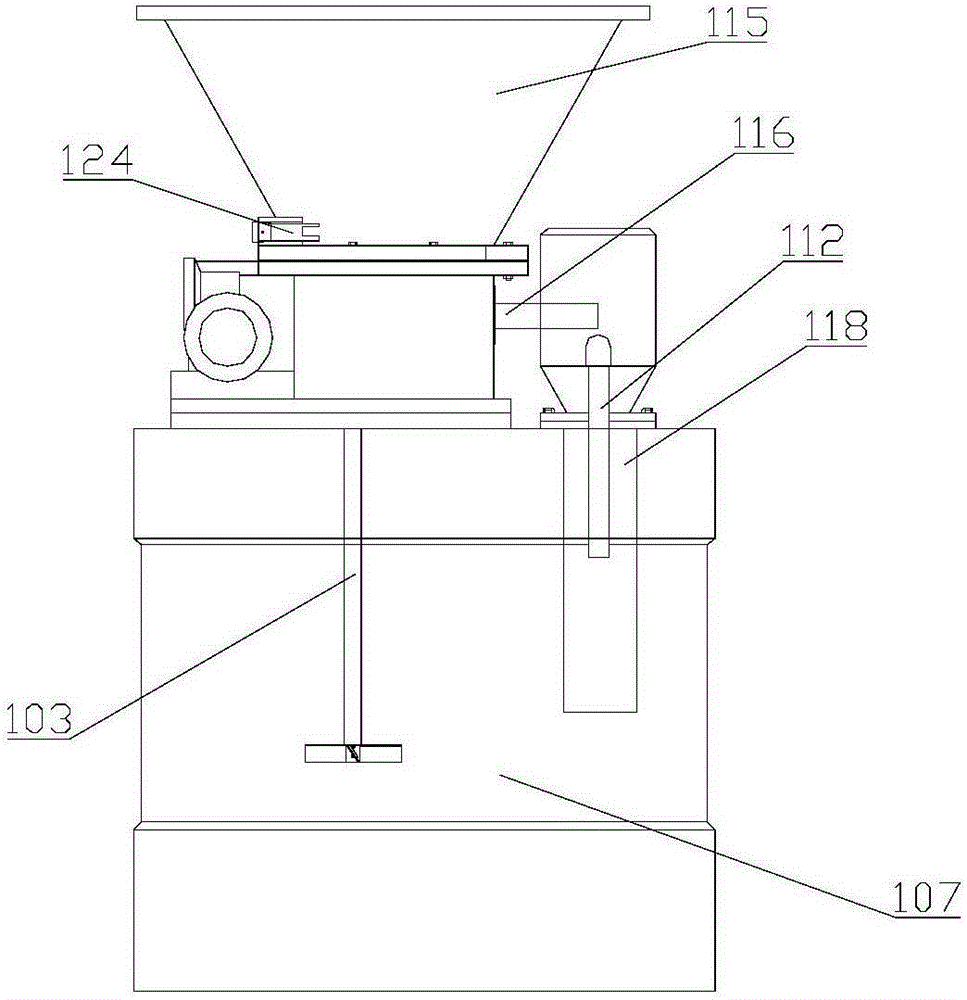

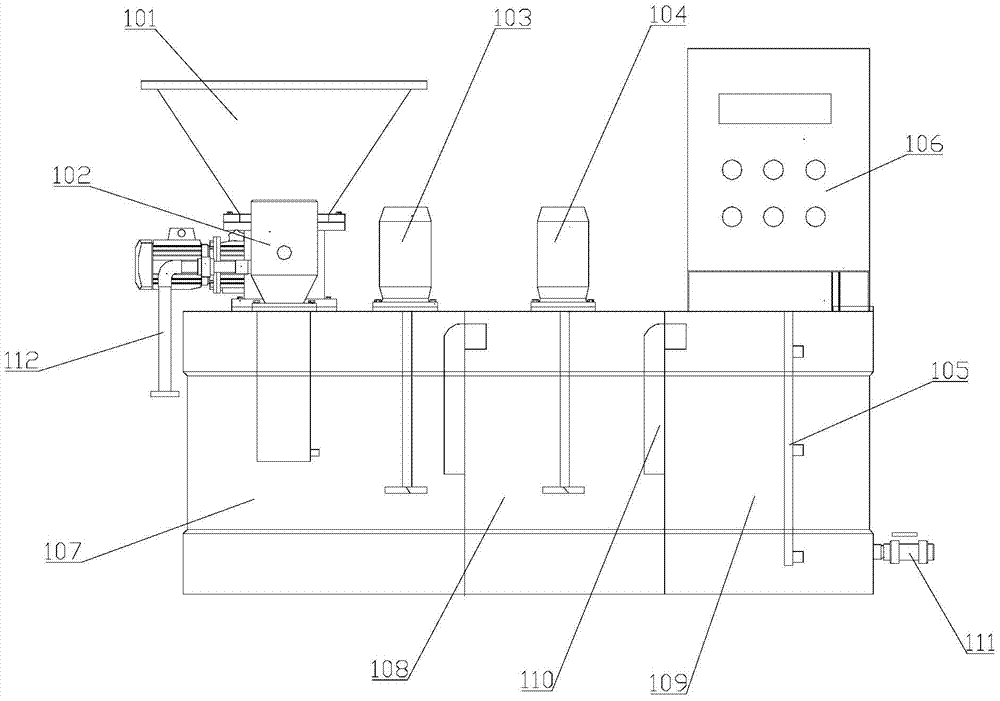

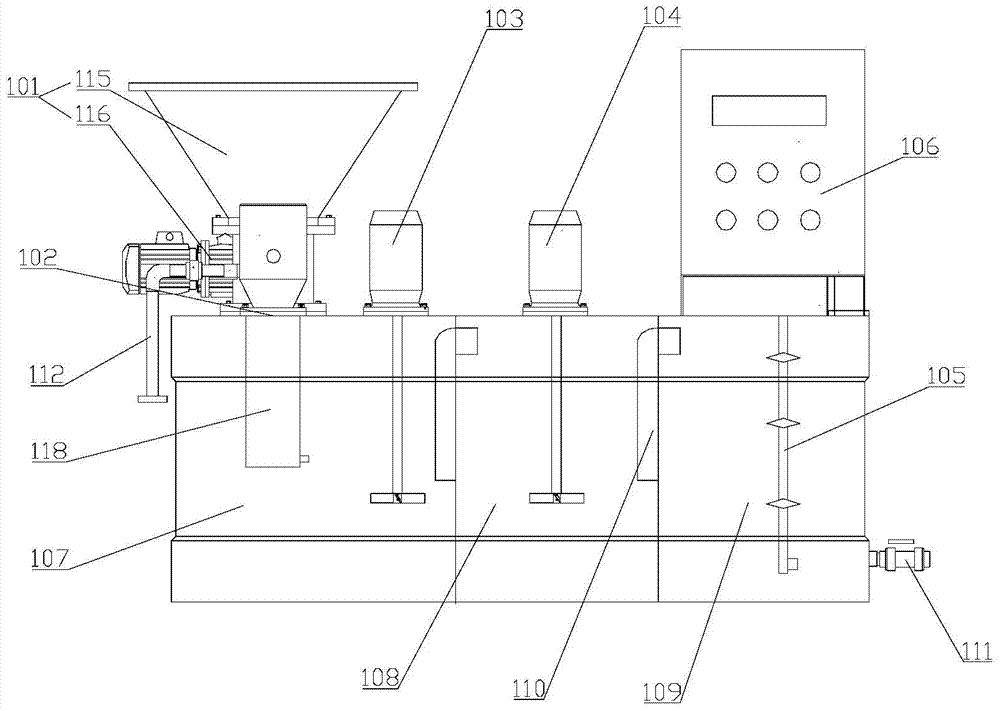

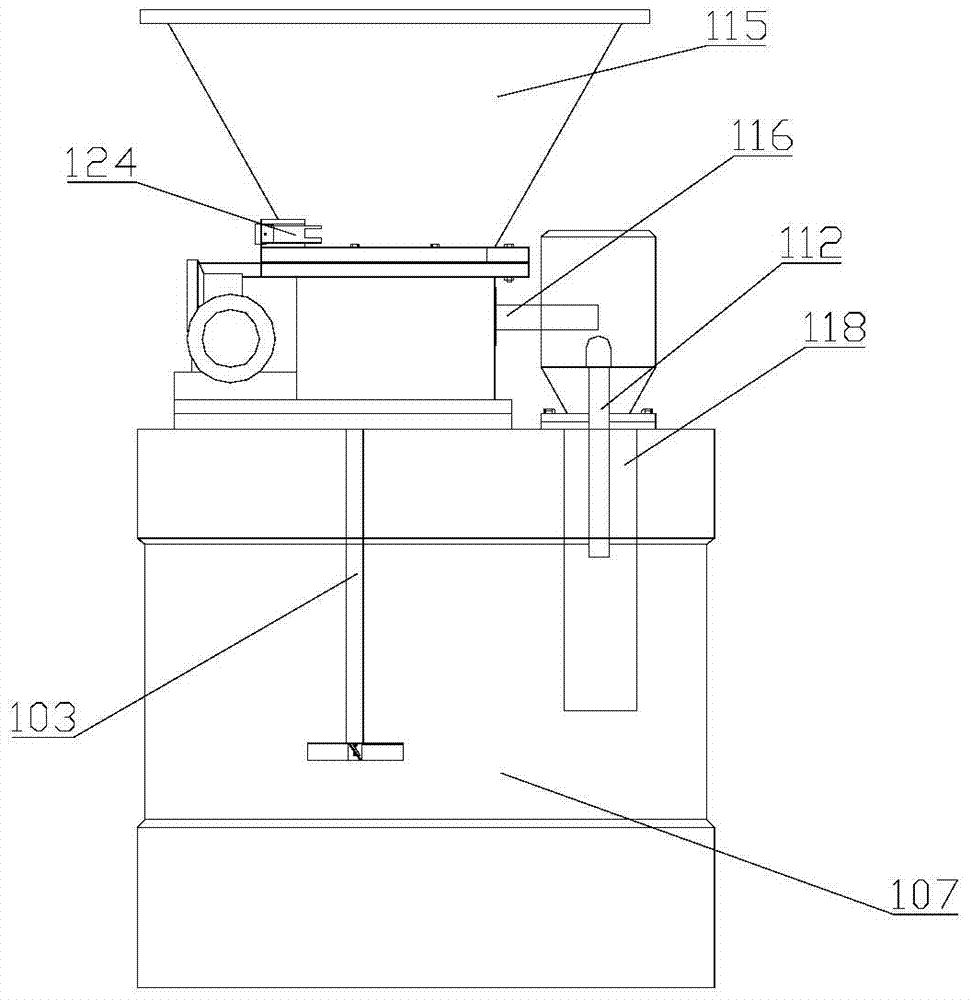

Automatic solution preparation device and powder body dissolution device

ActiveCN105169978ADissolve evenlyEfficient and uniform dissolutionMixersDissolvingElectricityEngineering

The invention provides an automatic solution preparation device and a powder body dissolution device, and relates to the field of chemical engineering. The automatic solution preparation device comprises a feeding mechanism, a pre-dissolution mechanism, a first stirring mechanism, a second stirring mechanism, a liquid level controller, an electric control mechanism, a dissolution box, a curing box and a finished product box, wherein the dissolution box, the curing box and the finished product box are sequentially in adjacent arrangement; the feeding mechanism is communicated with the pre-dissolution mechanism; the pre-dissolution mechanism is communicated with the inside of the dissolution box; the pre-dissolution mechanism is provided with a liquid inlet pipe; the first stirring mechanism is arranged in the dissolution box; the second stirring mechanism is arranged in the curing box; the liquid level controller is arranged in the finished product box; the electric control mechanism is respectively and electrically connected with the feeding mechanism, the pre-dissolution mechanism, the first stirring mechanism, the second stirring mechanism, the liquid level controller and the liquid overflowing pipe. When the device and the method provided by the invention are adopted, the dissolution of solutes in solvents is very efficient and uniform; the linear dissolution can be effectively avoided; the quality of the solution can be ensured; meanwhile, the automation degree is high; the device and the method are suitable for mass automatic production.

Owner:临沂龙软企业管理咨询有限公司

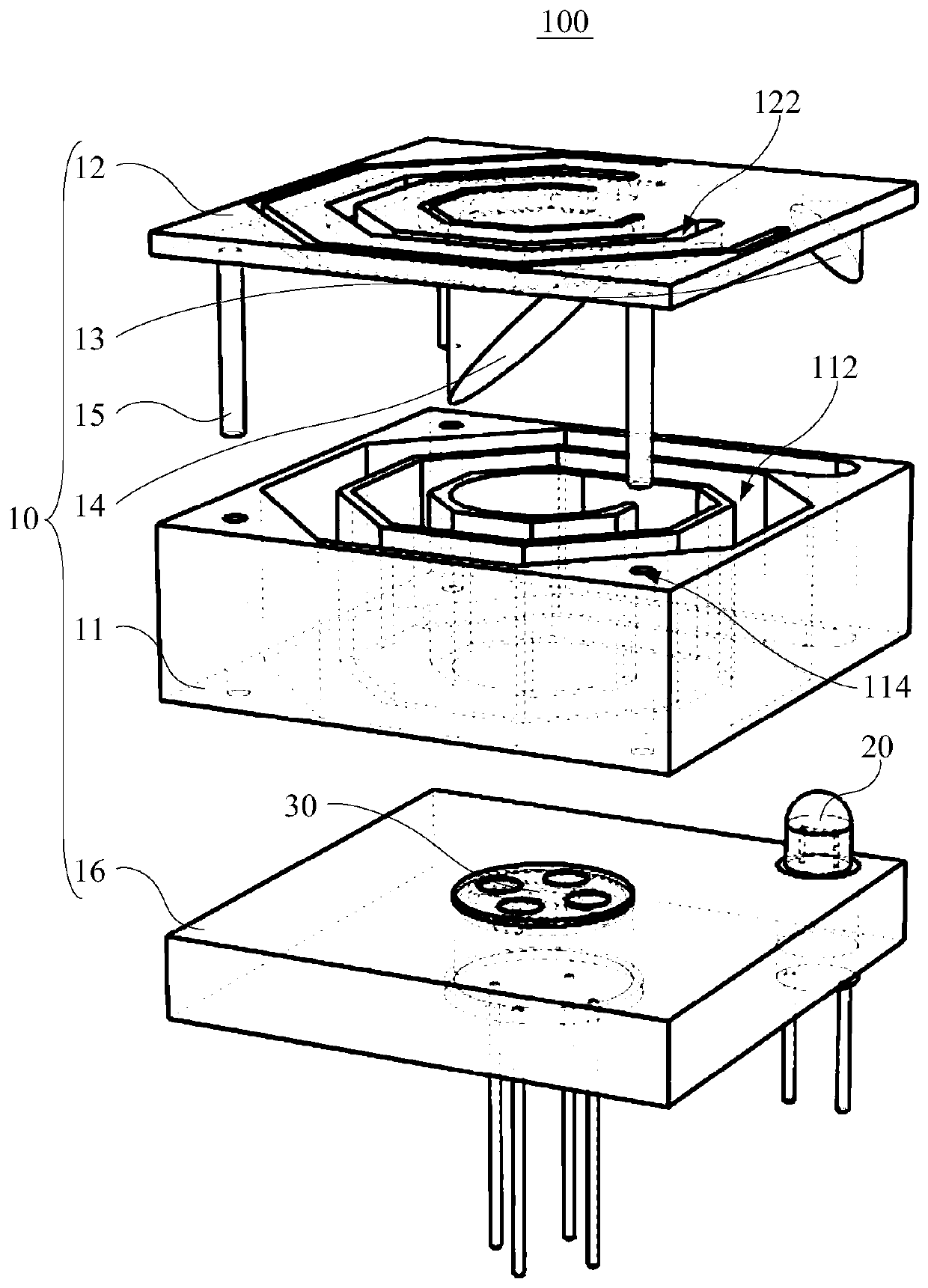

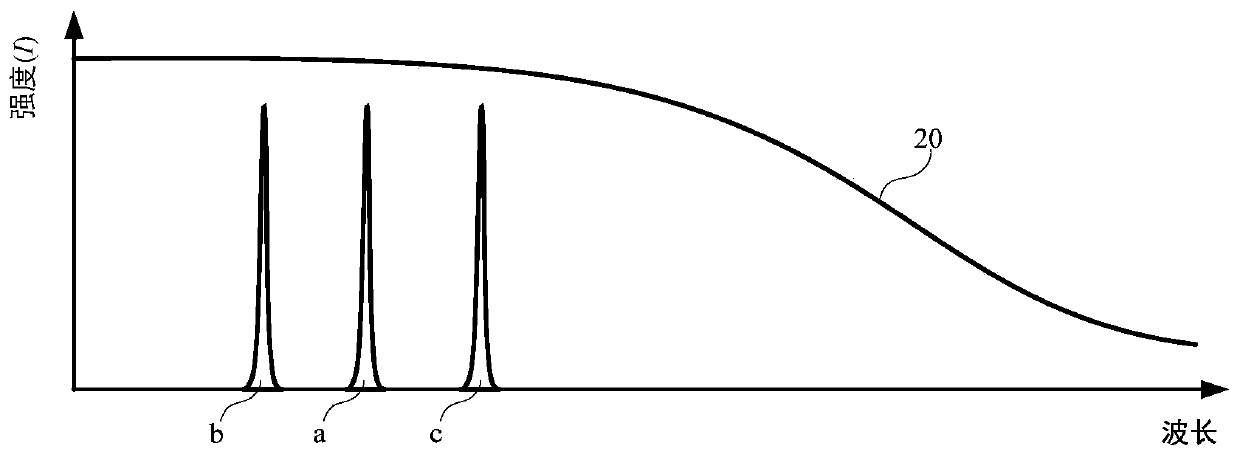

Multi-gas concentration detection device, manufacturing method thereof and alarm device

PendingCN110361354AOptimize space utilizationHigh degree of integrationColor/spectral properties measurementsMid infraredLight source

The invention provides a multi-gas concentration detection device, a manufacturing method thereof and an alarm device. The multi-gas concentration detection device comprises a reflection gas chamber,a mid-infrared light source, light filters and a multi-channel detector; a first through hole and a second through hole are formed in the reflection gas chamber; the mid-infrared light source is inserted into the first through hole; the light filters at least comprise a reference light filter, a first light filter and a second light filter; the multi-channel detector at least comprises a referencechannel, a first channel and a second channel which are all located on the same plane and face the second through hole; the reference light filter covers the light inlet of the reference channel; thefirst light filter covers the light inlet of the first channel; the second light filter covers the light inlet of the second channel; and light emitted by the mid-infrared light source is gathered into the reference channel, the first channel and the second channel through the reflection air chamber. The multi-gas concentration detection device can synchronously detect the concentrations of various gases and mixed gases thereof.

Owner:SHENZHEN NUOAN ENVIRONMENTAL & SAFETY INC

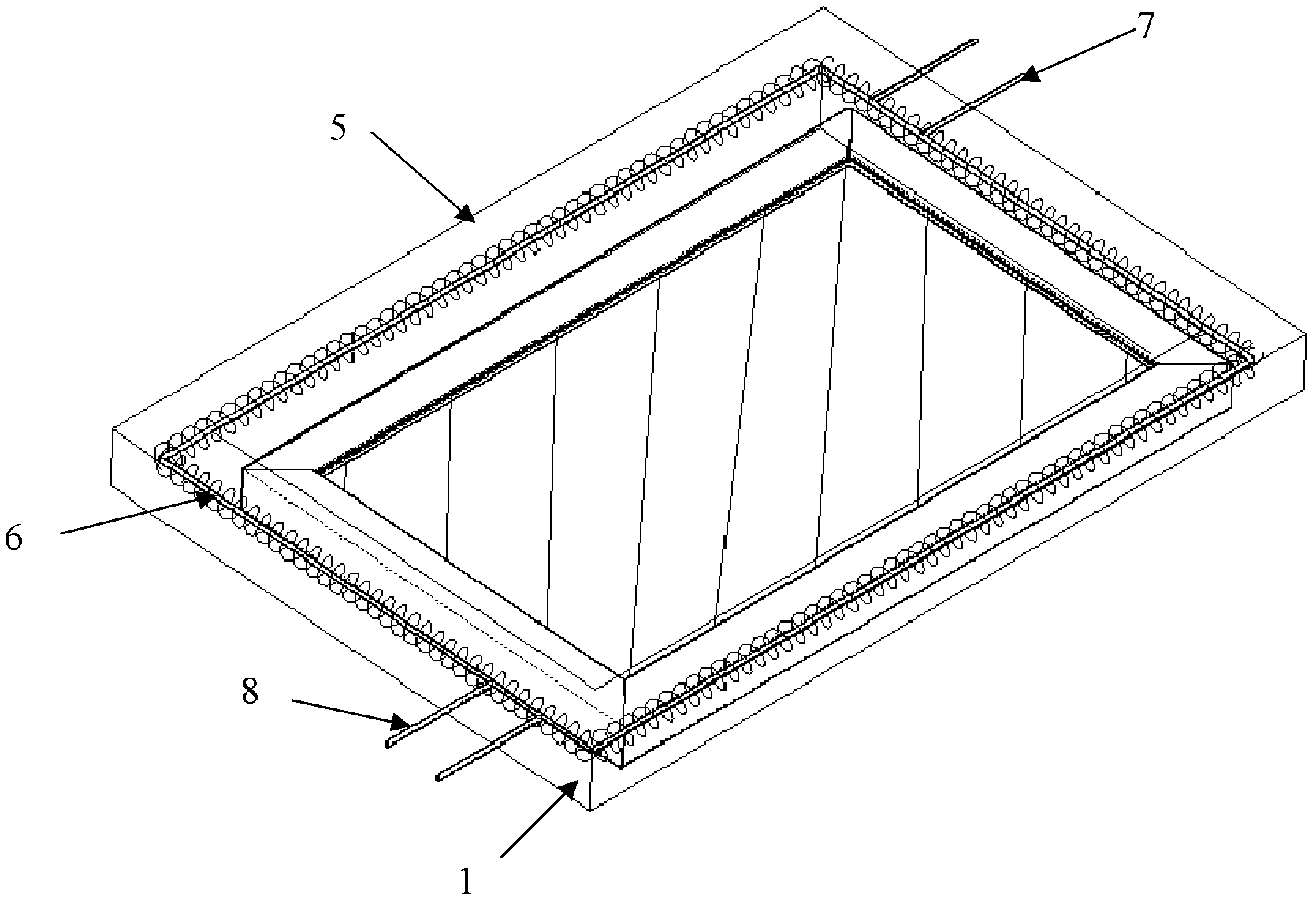

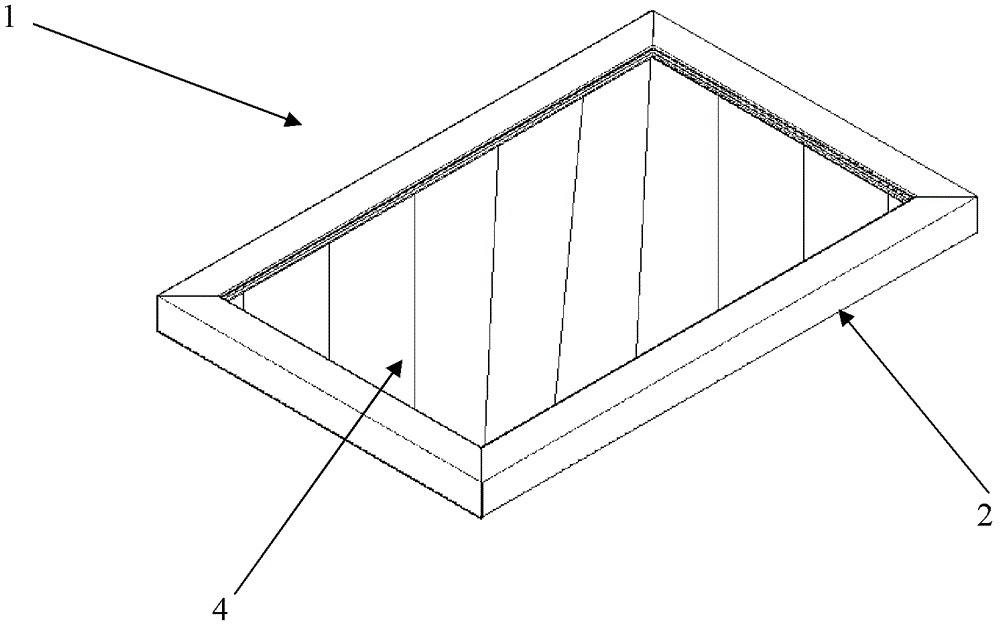

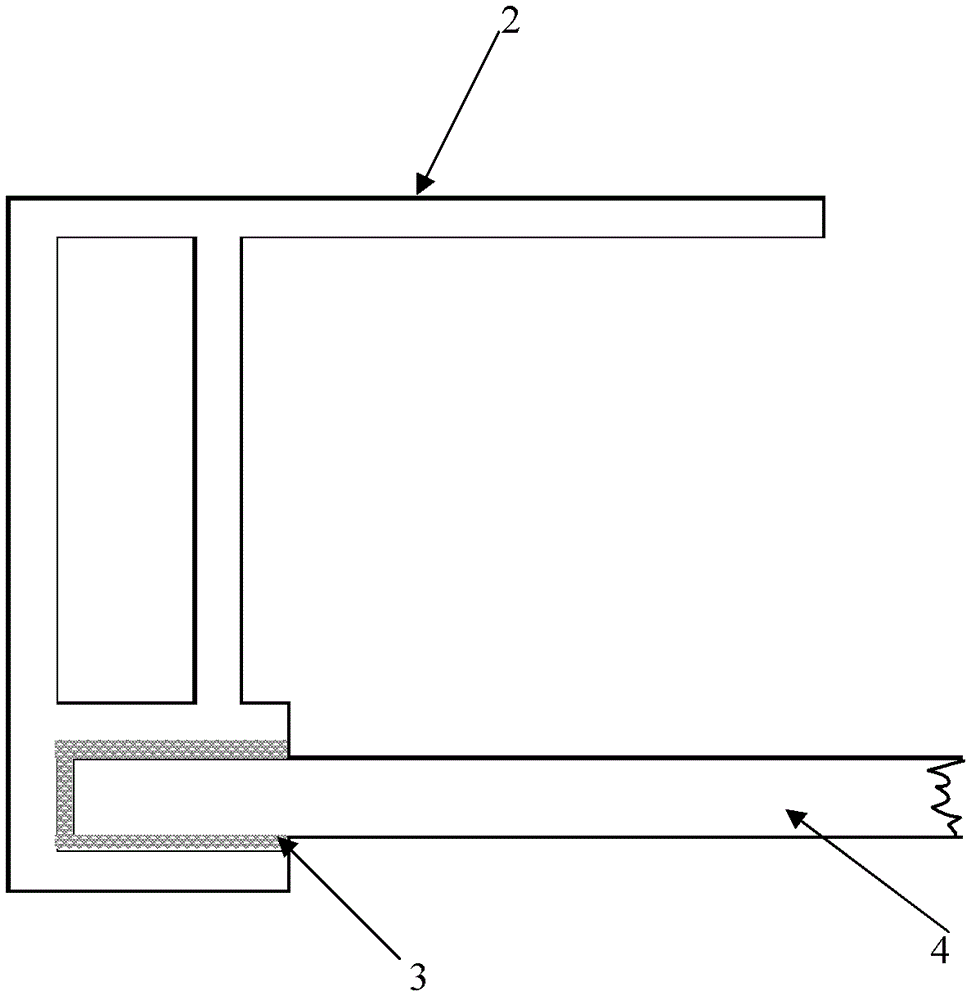

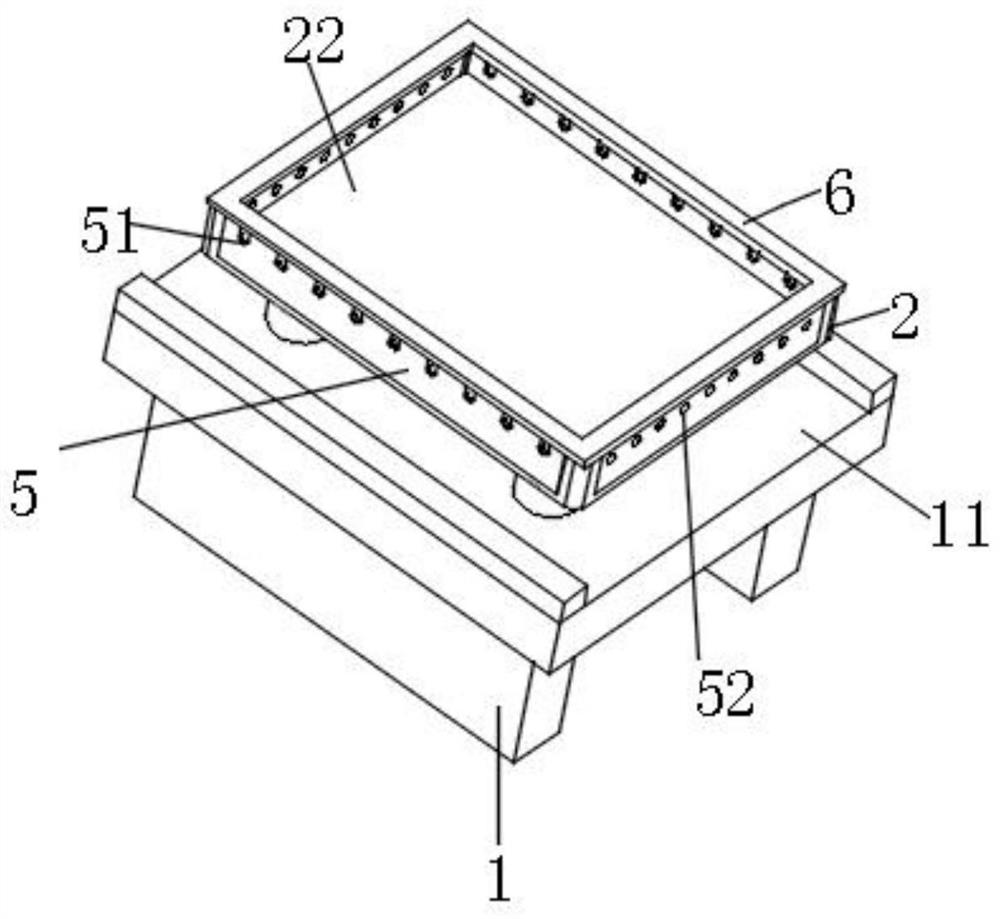

Induction sealing method for solar component

ActiveCN102916072ALow costMeet long working hoursFinal product manufactureSemiconductor devicesEngineeringInduction method

The invention provides an induction sealing method for a solar component. According to the induction sealing method, the solar component provided with a frame, sealing material and a solar laminated panel is arranged under an induction sealing head, the aluminum frame generates induction current inside under the action of the magnetic field of the sealing head, then the electric energy is converted into heat energy, the sealing material is gradually heated under the action of the heat energy to wrap and adhere the edge of the solar laminated panel and a groove of the aluminum frame and fill the gap between the edge of the solar laminated panel and the groove of the aluminum frame, so that the sealing effect is played. According to the induction sealing method specially designed for the solar component, the technology is simple, the sealing method is safe and environment-friendly, the sealing time is short, and the encapsulation effect for the solar component is superior.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

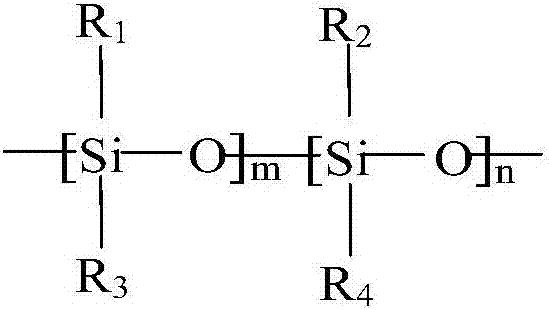

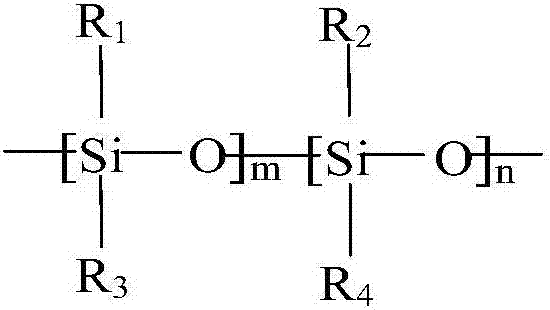

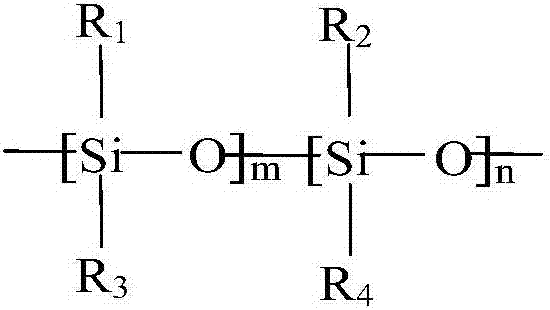

Silica gel spectacle frame and preparation technology thereof

The invention discloses a silica gel spectacle frame and a preparation technology thereof. The preparation technology comprises the steps of mixing raw silica gel with filler, continuing to add a vulcanizing agent, a catalyst and a chain extender and evenly stirring to obtain a pre-injection sizing material; injecting the pre-injection sizing material into moulds of spectacle legs, the spectacle frame and connection parts, vulcanizing the sizing material and release pressure to normal pressure after vulcanizing; curing, cooling and demoulding obtained prefabricated parts; connecting and assembling silica gel finished products of the obtained spectacle legs, the spectacle frame and the connection parts through metal screws and nuts to obtain the silica gel spectacle frame. The silica gel spectacle frame prepared by the preparation technology disclosed by the invention has extremely high biocompatibility and skin comfort degree, convenience in wearing and easiness in maintenance.

Owner:温州佳宏百丽科技有限公司

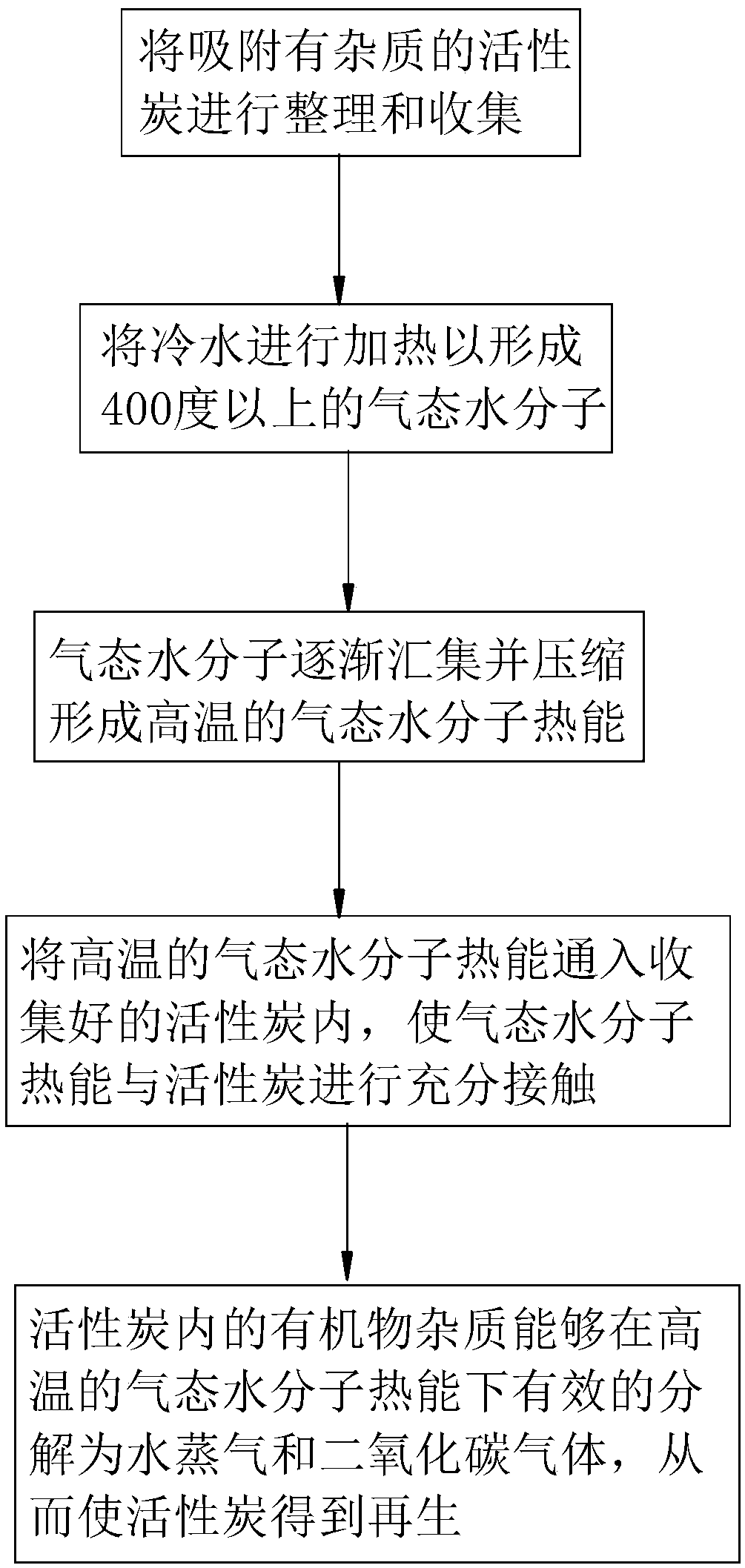

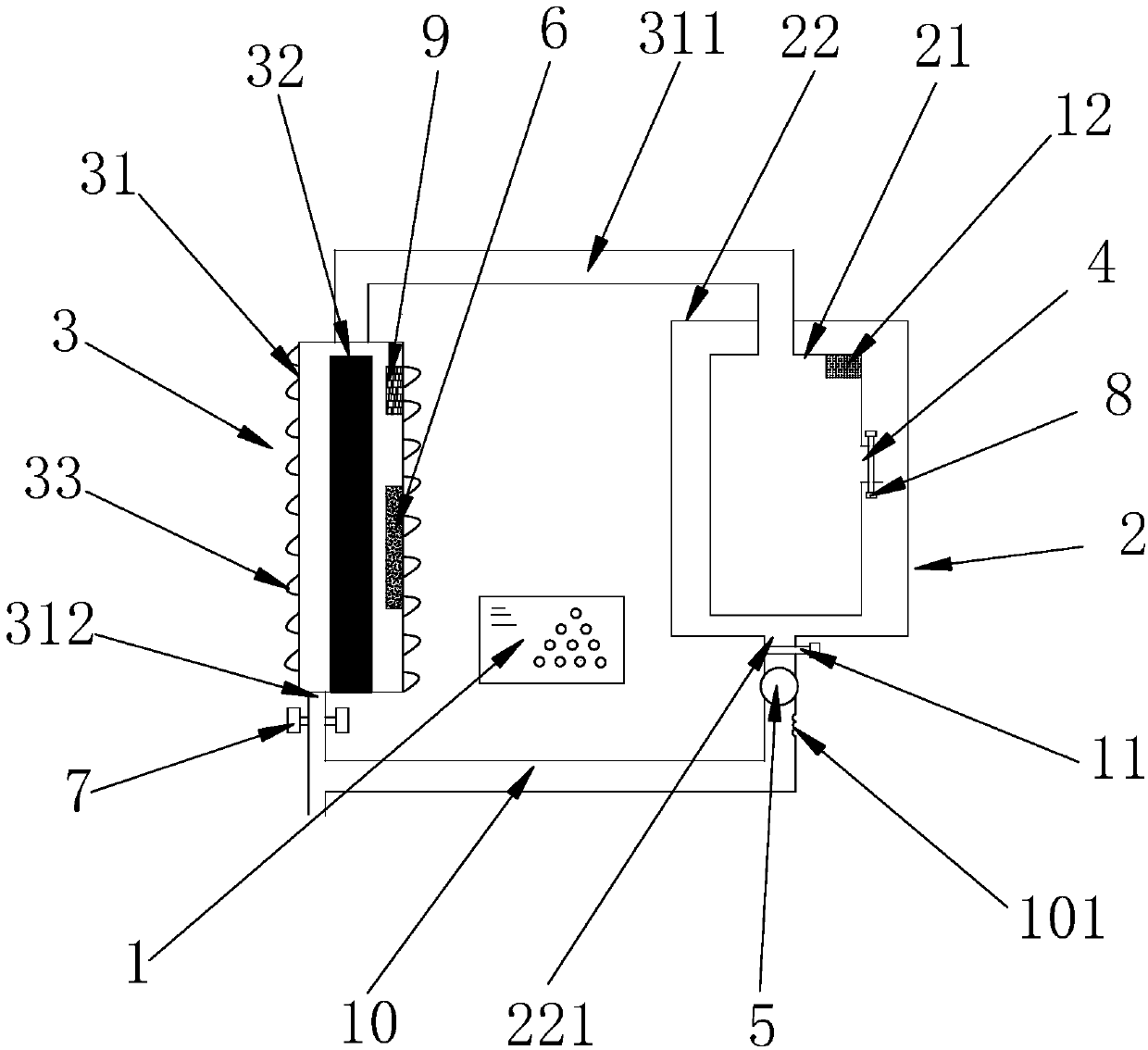

Regeneration method of active carbon and device for realizing method

PendingCN107597085AReduce lossShort regeneration timeOther chemical processesCombustible gas purificationWater vaporEngineering

The invention provides a regeneration method of active carbon. The regeneration method comprises the following steps that collection and arrangement are carried out on used active carbon; water is introduced into a water-molecule heat-energy generation device to obtain high-temperature gaseous water-molecule heat energy with the high enthalpy value; the outputted gaseous water-molecule heat energyis directly introduced into the collected and arranged active carbon, the high-temperature gaseous water-molecule heat energy can react with organic-matter impurities in the active carbon, and then the organic-matter impurities can be decomposed by heat to form steam, carbon dioxide, carbon black and other foreign gases, so that the active carbon is regenerated. The regeneration method provided by the invention has the advantages that the impurities in the active carbon can be effectively cleared by the formed high-temperature gaseous water-molecule heat energy under normal pressure so as toachieve the purpose of active-carbon regeneration; the principle is reliable, the process is simple and the carbon loss is less. The invention also provides a device for realizing the regeneration method of the active carbon. The device has the advantages of simple whole structure, convenience in use, more miniaturization, lower cost and wide application range.

Owner:GUANGZHOU BAOSHI WIRELESS POWER SUPPLYING TECH CO LTD

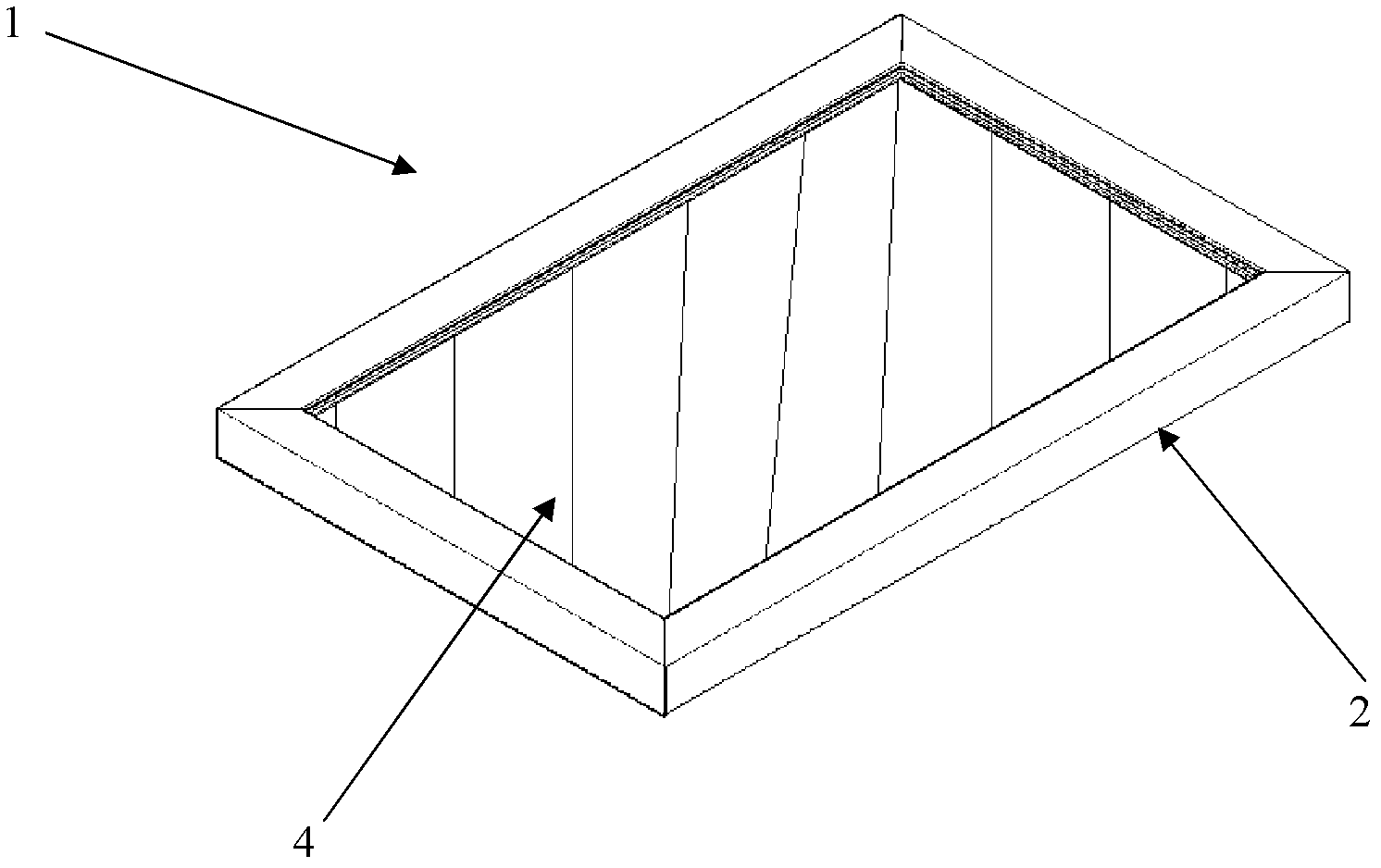

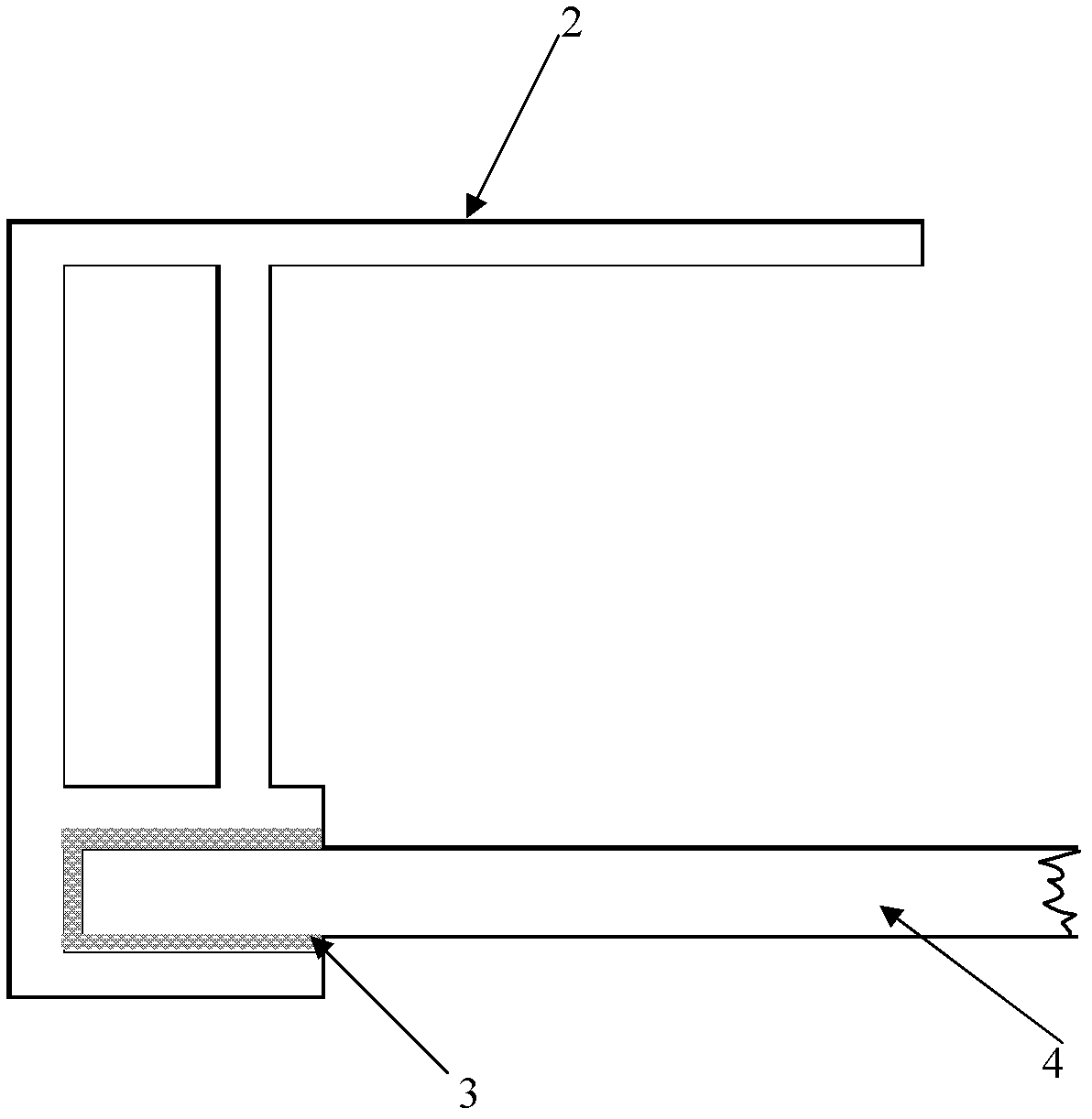

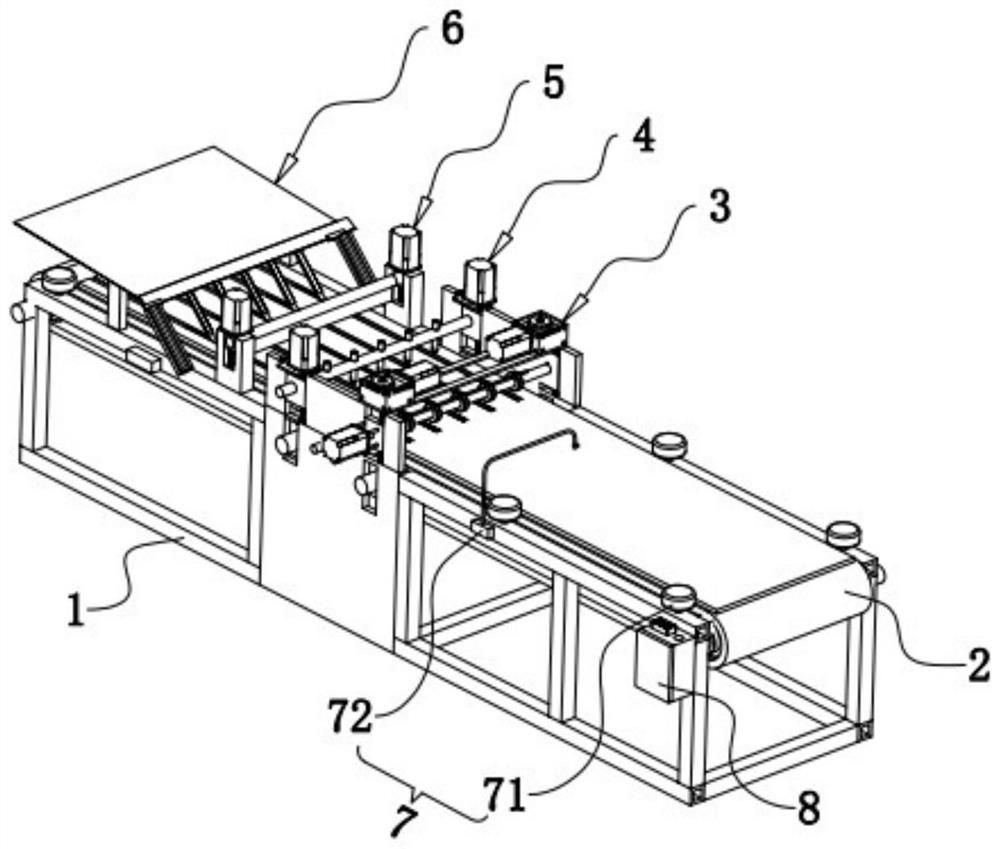

Vacuum insulated panel processing equipment and processing method

PendingCN114211546ASuitable for large-scale automated productionSimple structureMetal working apparatusManufacturing engineeringVacuum insulated panel

The invention provides vacuum insulation panel machining equipment and a machining method, and relates to the technical field of vacuum insulation panel machining. The conveying device is fixed on the rack and is used for conveying the vacuum insulated panel; the first cutting device is movably arranged on the rack and is used for pre-grooving the vacuum insulated panel and forming a strip-shaped core material; the second cutting device is movably arranged on the rack and is used for cutting off the strip-shaped core material; the third cutting device is arranged on the rack in a lifting manner and is used for cutting off the vacuum insulated panel; the fourth cutting device is connected to the rack in a sliding manner and is used for cutting and separating the strip-shaped core material from the vacuum insulated panel; and the first cutting device, the second cutting device, the third cutting device and the fourth cutting device are sequentially arranged at intervals in the conveying direction of the vacuum insulated panel. According to the equipment, in the grooving machining procedure of the vacuum insulation panel, the design requirement can be met without secondary machining, the production efficiency is greatly improved, and the quality risk caused by secondary machining is further reduced.

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

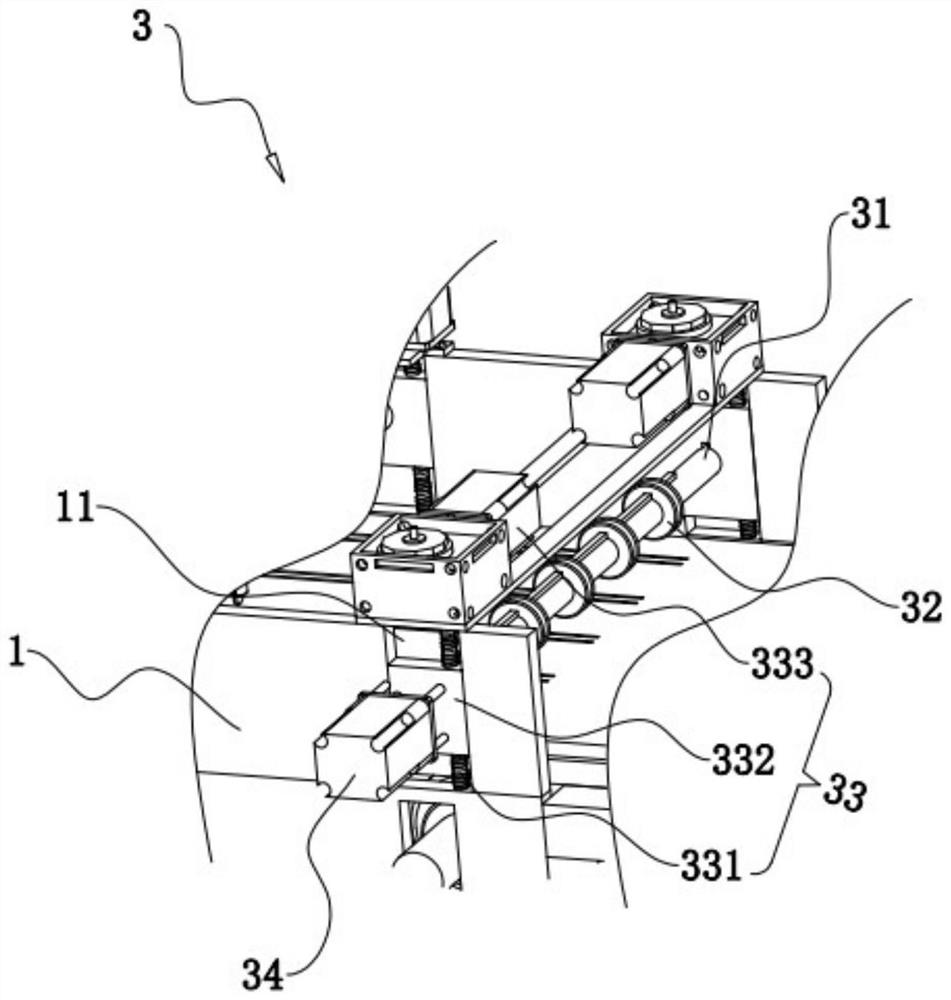

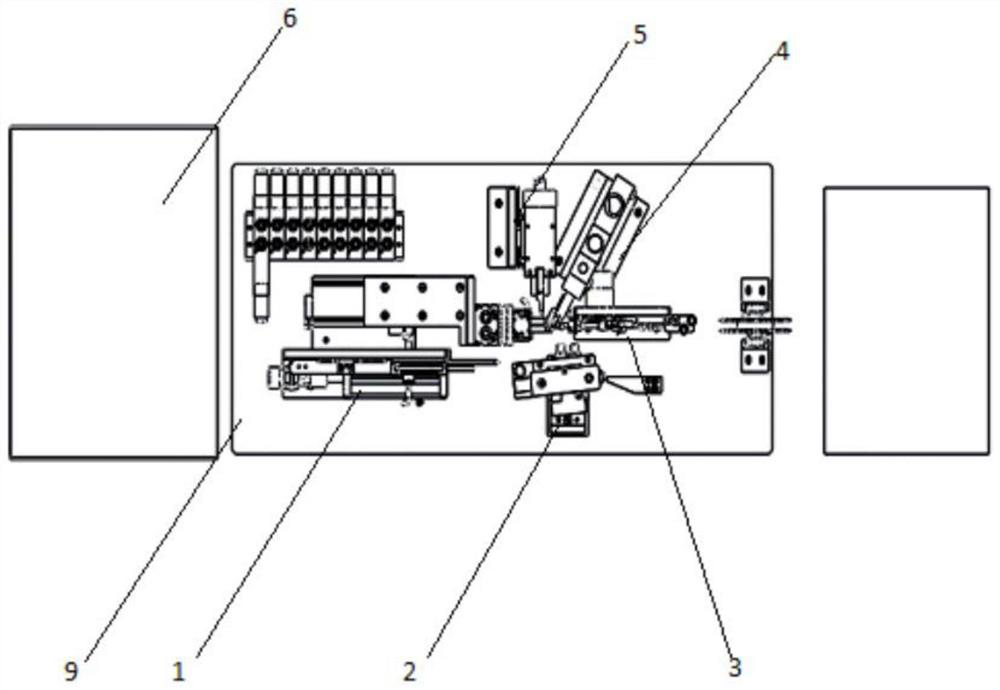

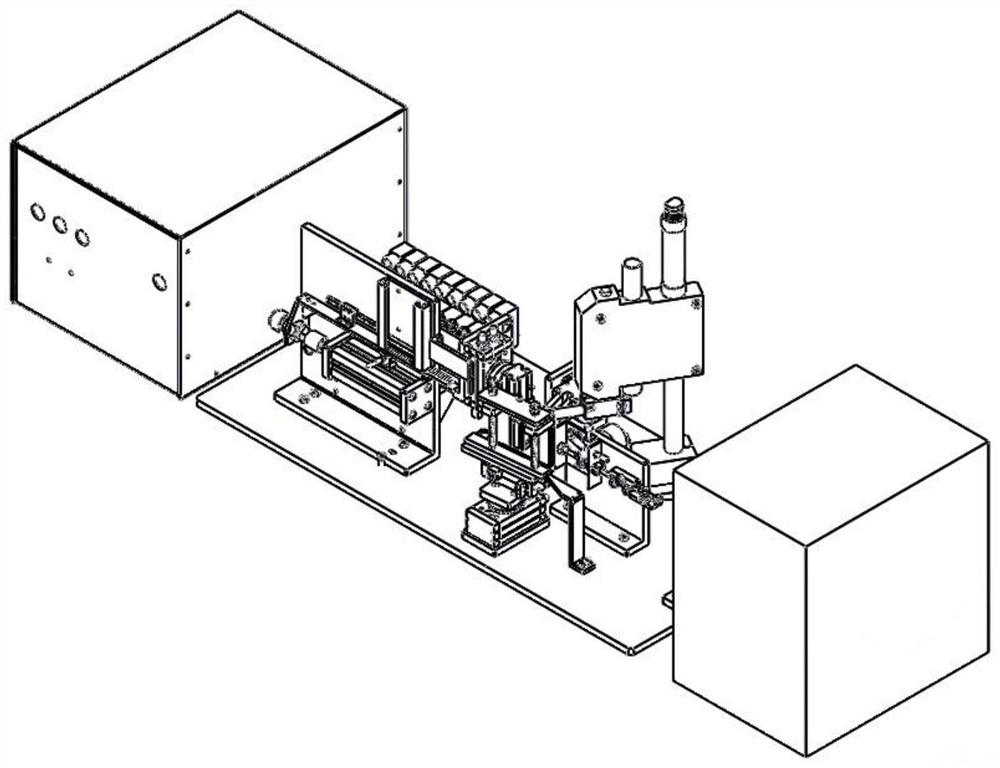

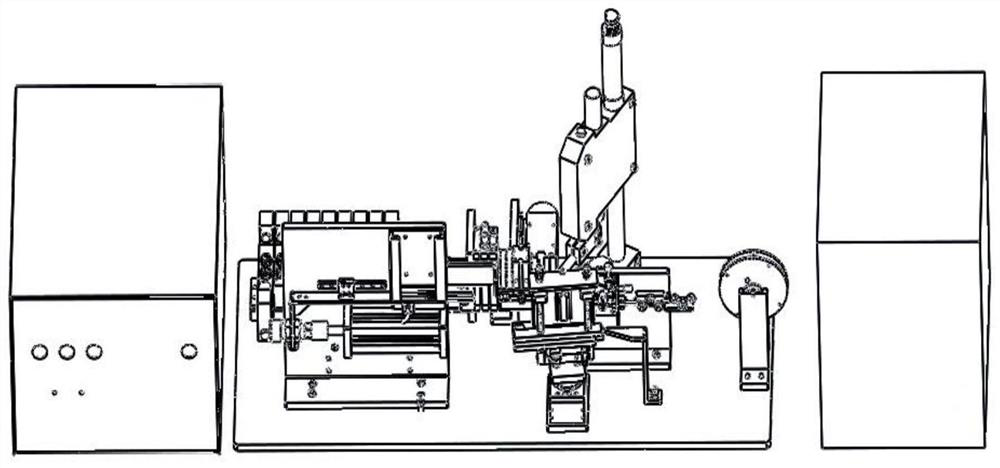

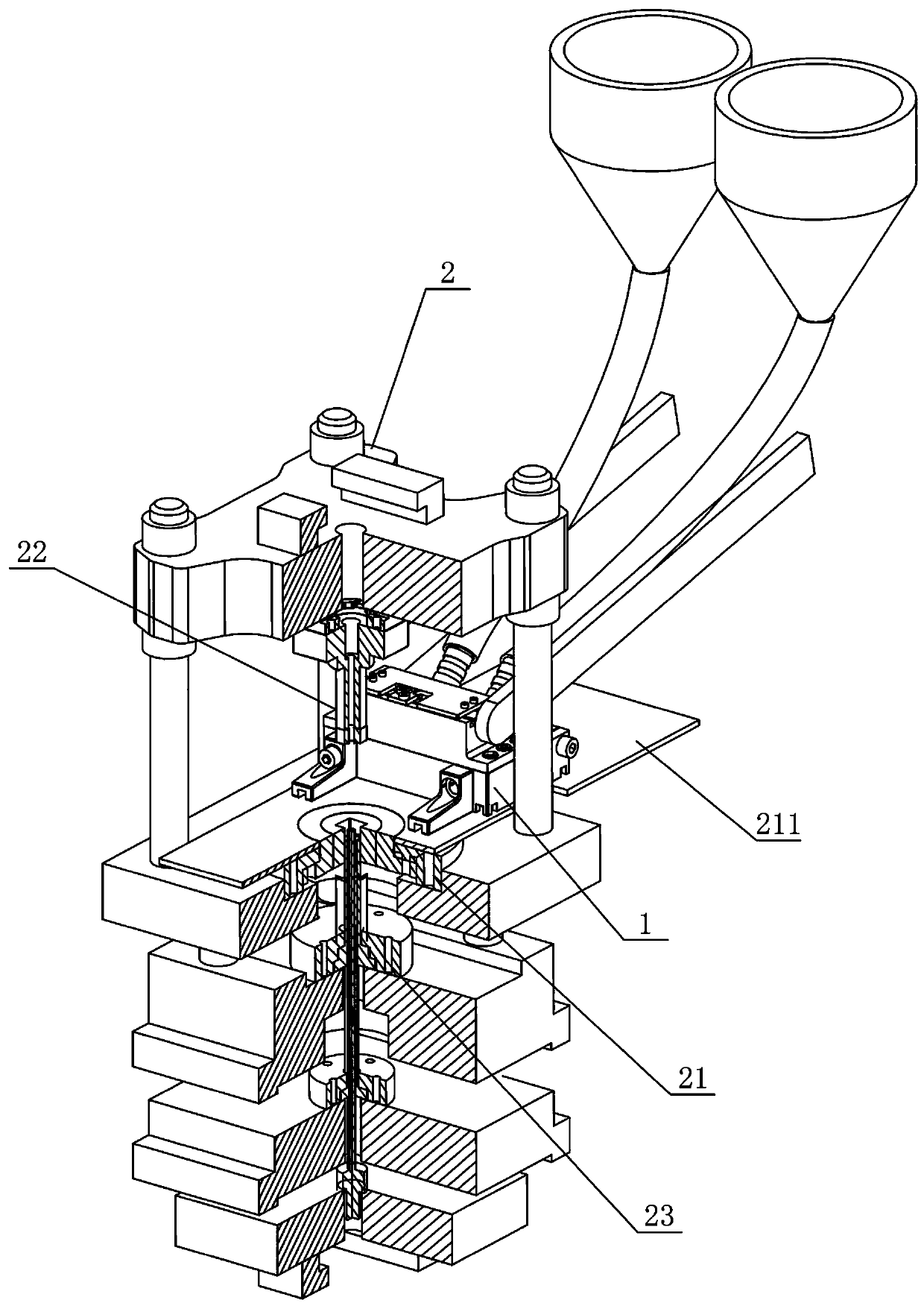

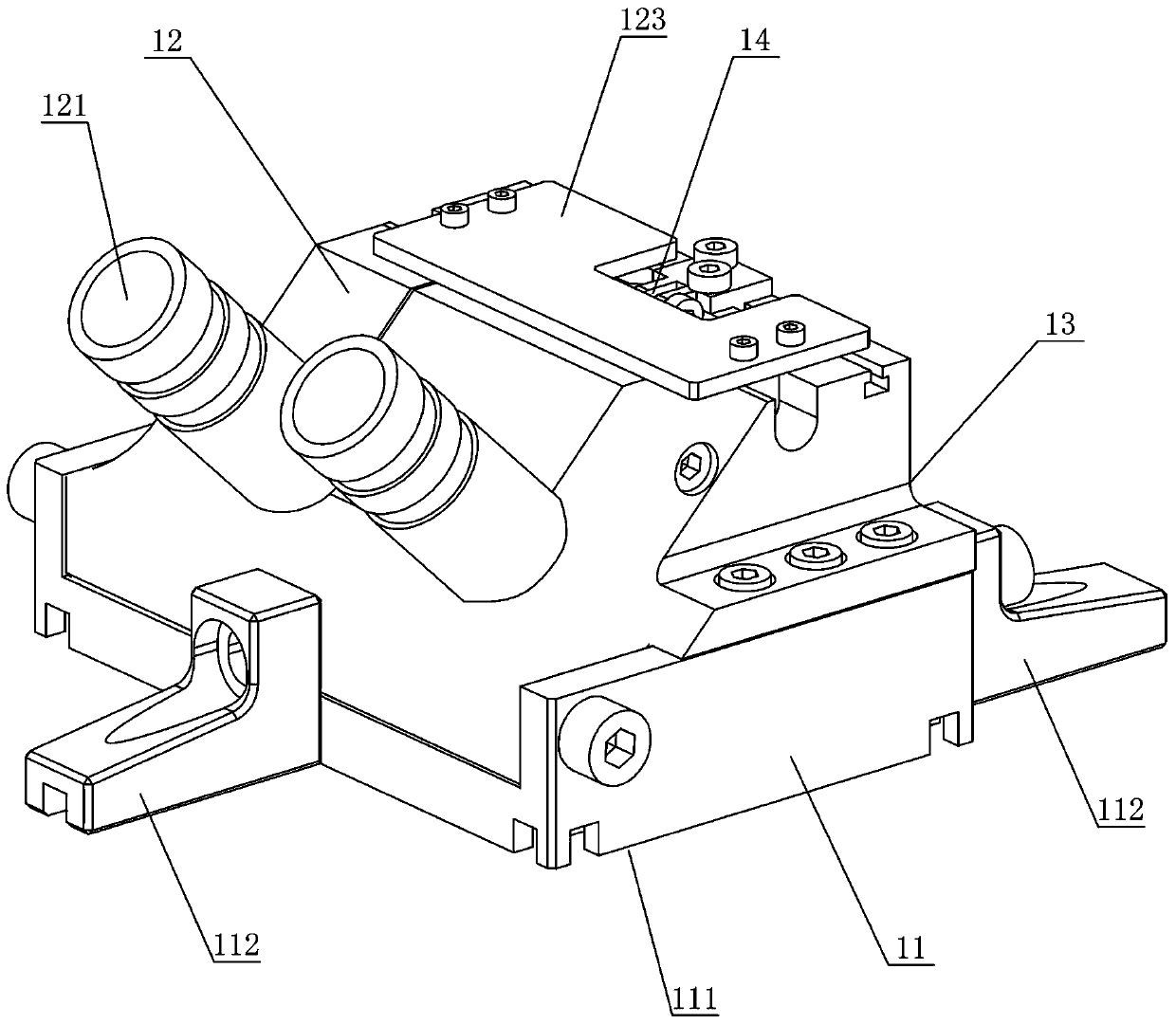

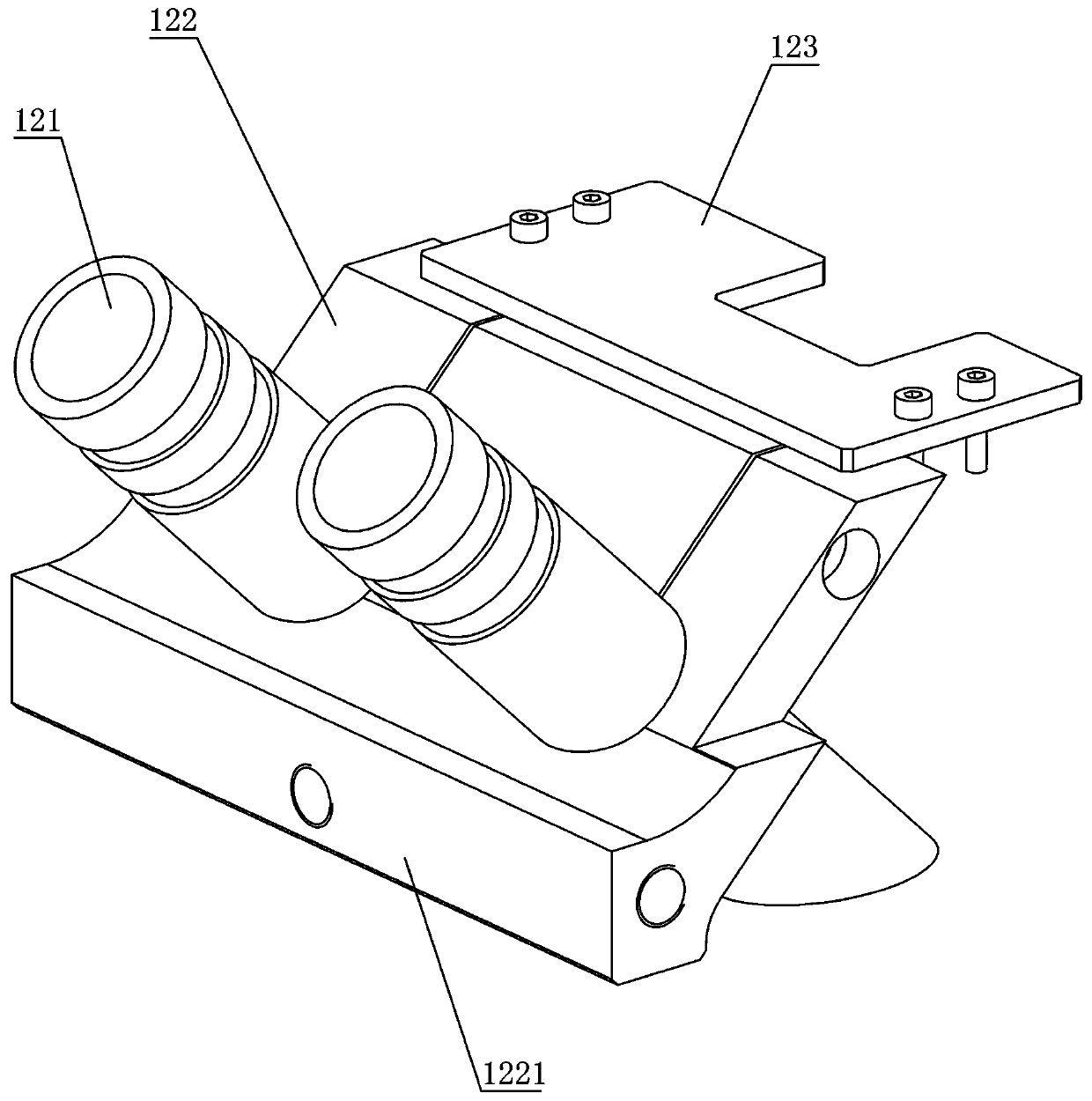

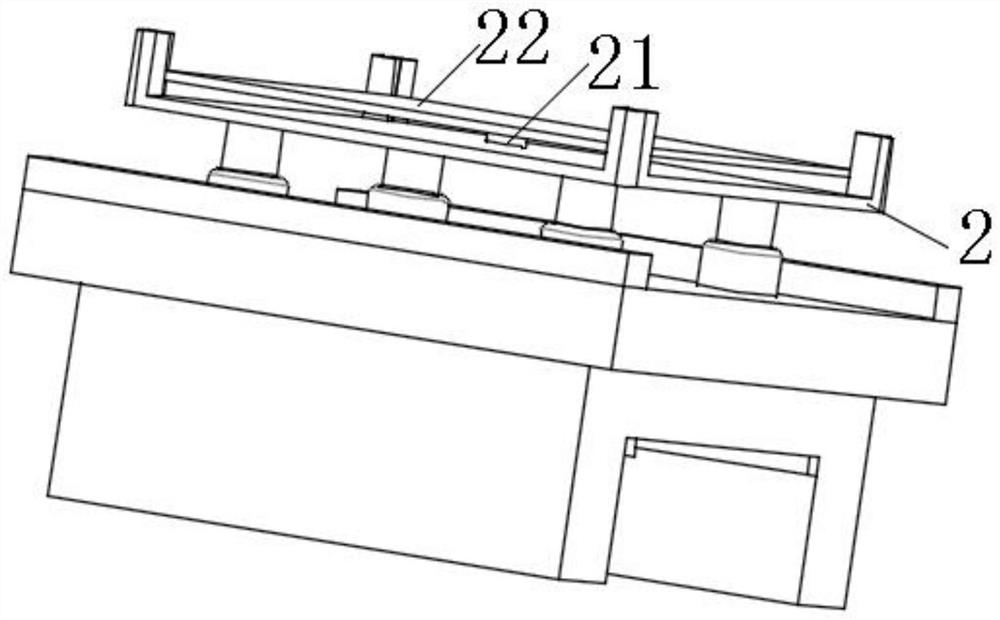

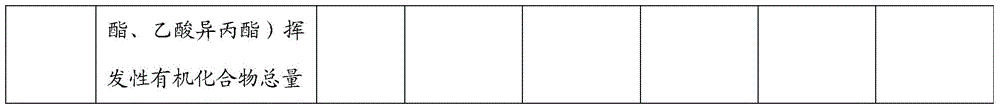

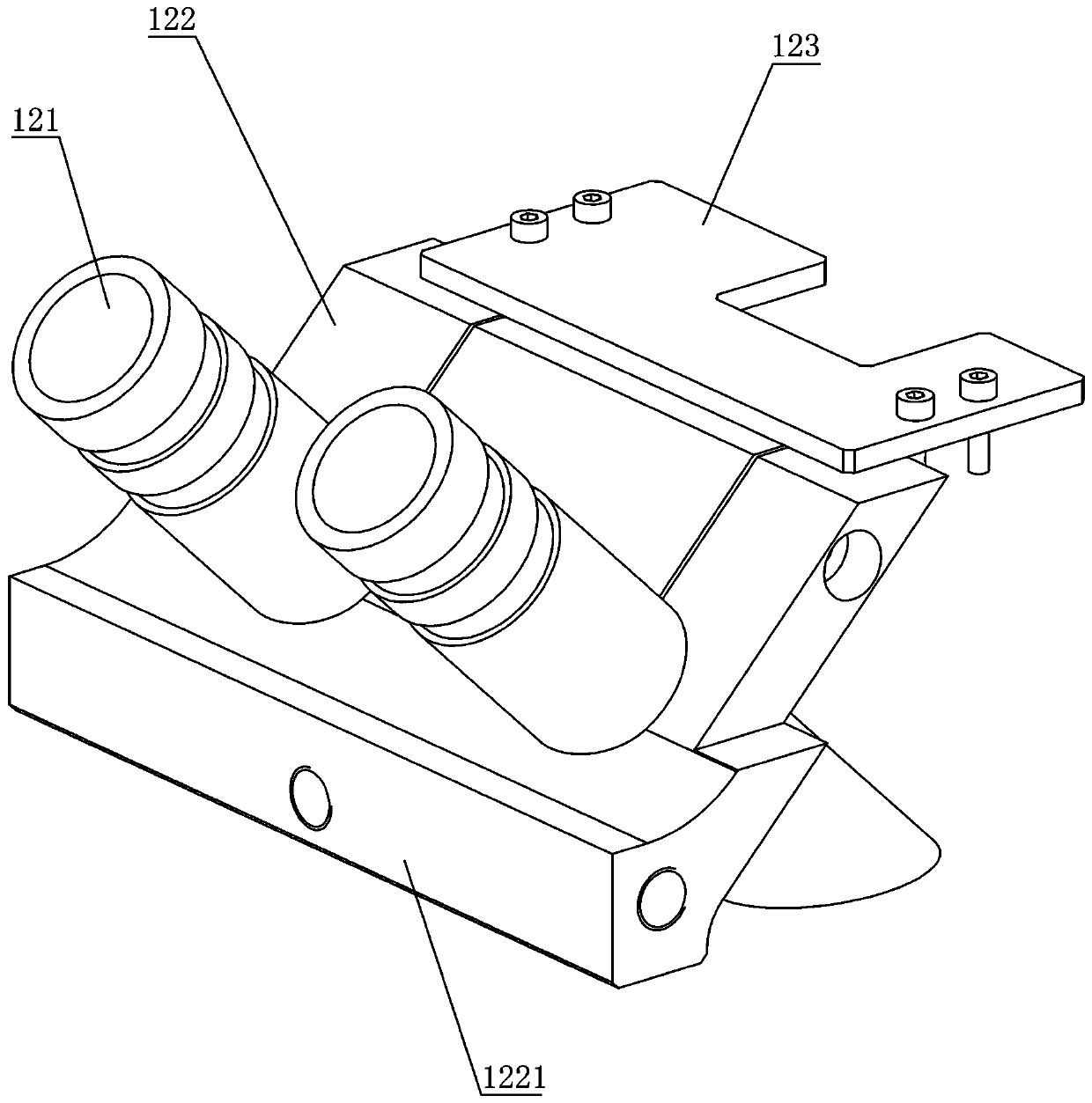

Micro thermocouple threading device and machining method

PendingCN113385925AReduce labor intensityImplement auto-completionMetal working apparatusWelding apparatusThermocouple WireLap joint

The invention discloses a micro thermocouple threading device and a machining method, and belongs to the technical field of thermocouple manufacturing. The micro thermocouple threading device comprises a material storing and feeding mechanism, a thermocouple wire clamping mechanism, a wire feeding mechanism, a welding mechanism, a shearing mechanism and a machining platform, wherein the material storing and feeding mechanism conveys a U-shaped quartz long tube to a threading area above the machining platform; the wire feeding mechanism enables a traction wire to penetrate through the U-shaped quartz long tube and conveys the traction wire to a welding area above the machining platform; the thermocouple wire clamping mechanism is used for clamping a thermocouple wire and conveying the thermocouple wire after length comparison to the welding area above the machining platform to form lap joint with the thermocouple wire in the welding area; the welding mechanism is used for welding the thermocouple wire and the traction wire in the welding area; and the shearing mechanism shears off the redundant traction wire after the welded thermocouple wire and the traction wire move to the designated position, and therefore threading work is completed. Manual errors can be reduced, the threading efficiency is greatly improved, the production cycle of thermocouple products is shortened, and the labor intensity of operators is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

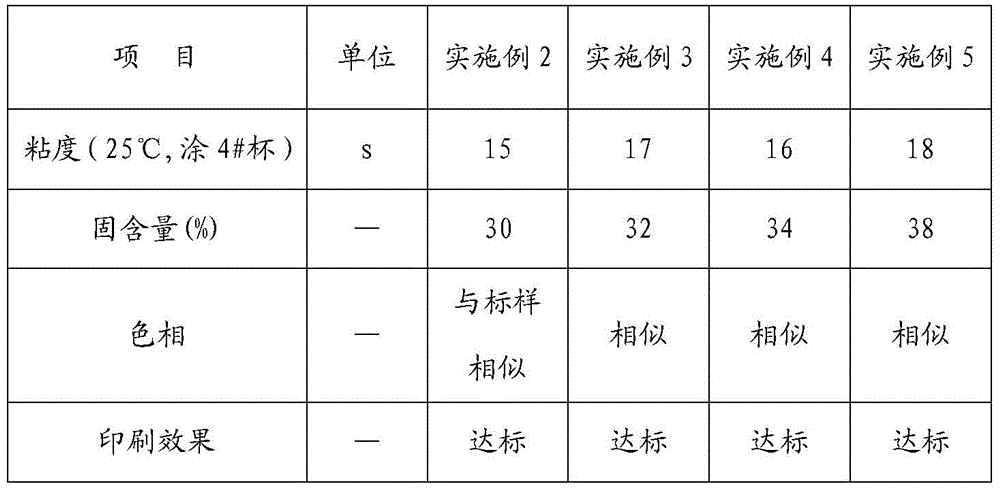

Ink capable of realizing cursor invisibility as well as preparation process and application of ink

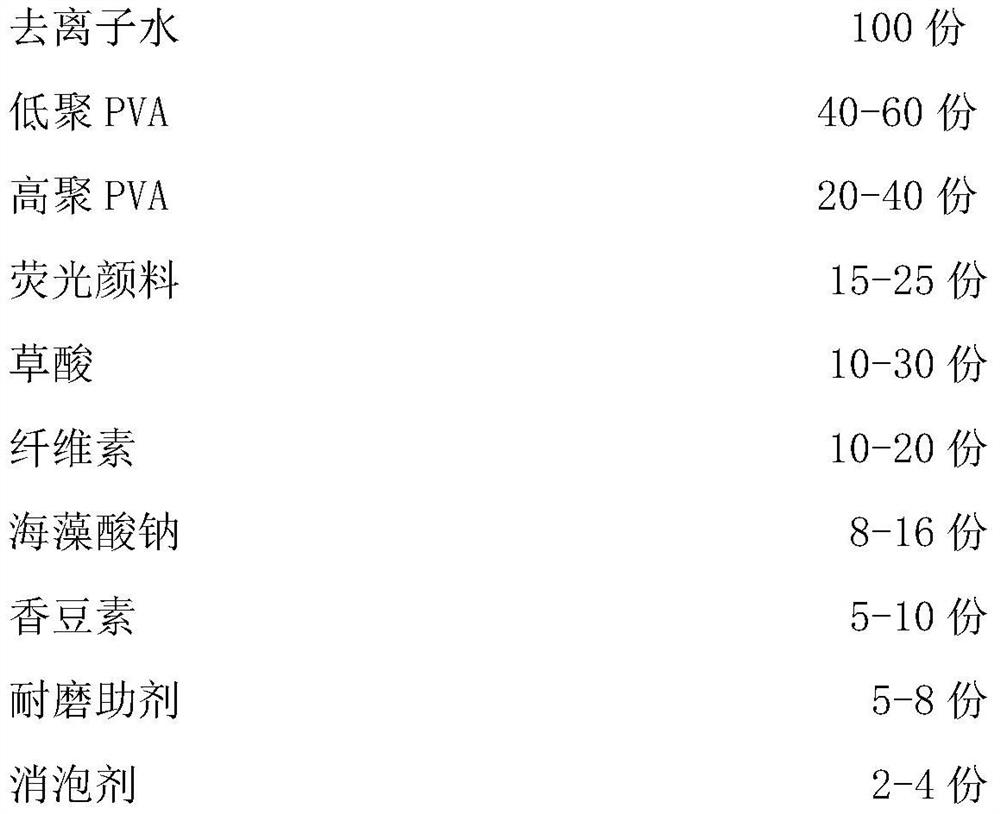

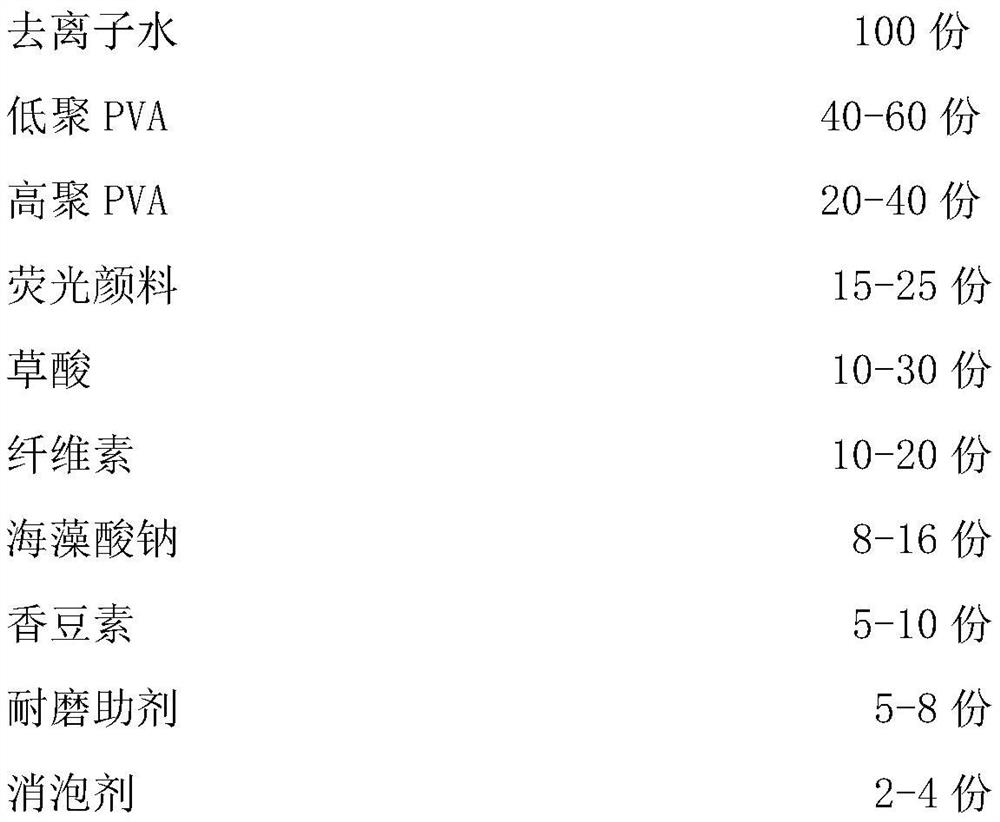

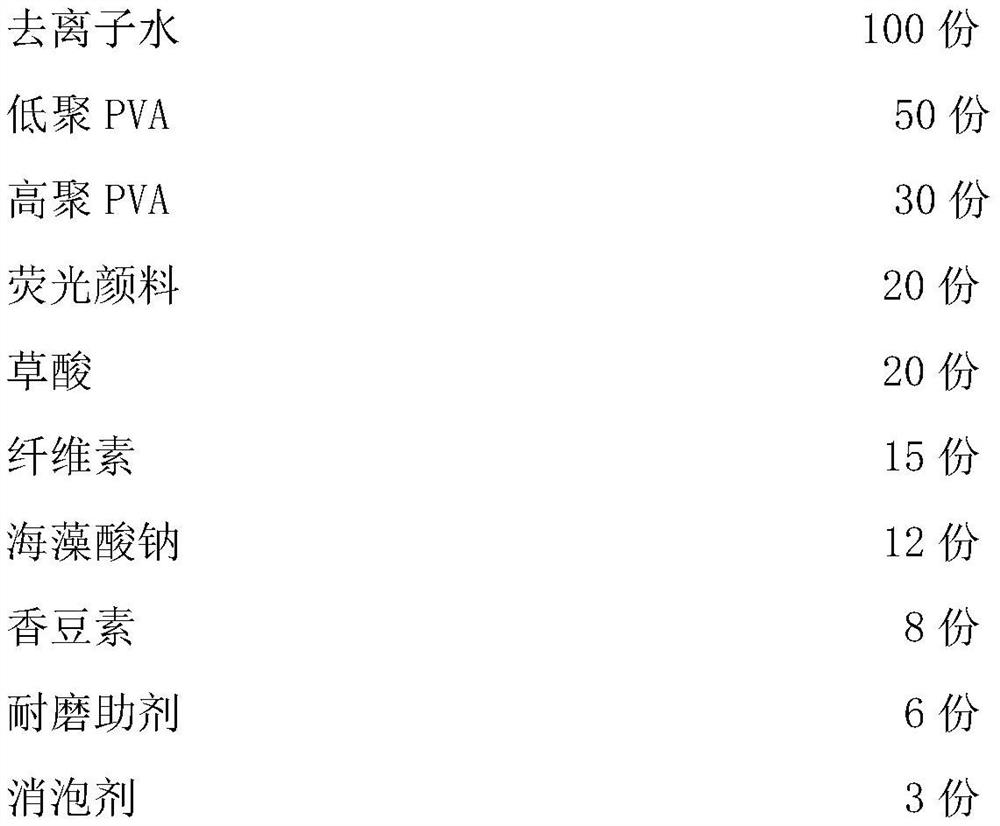

PendingCN113621271AHigh fluorescence intensitySimple ingredientsBox making operationsPaper-makingCelluloseOXALIC ACID DIHYDRATE

The invention belongs to the field of fluorescent ink, and particularly discloses ink capable of realizing cursor invisibility and a preparation technology and application thereof. The ink is prepared from, by weight, 100 parts of deionized water, 40-60 parts of oligomeric PVA, 20-40 parts of polymeric PVA, 15-25 parts of fluorescent pigment, 10-30 parts of oxalic acid, 10-20 parts of cellulose, 8-16 parts of sodium alginate, 5-10 parts of coumarin, 5-8 parts of wear-resistant auxiliaries, and 2-4 parts of a defoaming agent. The ink capable of realizing cursor invisibility disclosed by the invention is low in harmful component content, high in fluorescence intensity, environment-friendly in preparation method and good in effect when being applied to the field of bag making.

Owner:苏州宏昌包装材料有限公司

Device and method for marinating eggs

The invention relates to a device for marinating eggs, comprising an egg marinating pot, a hot marinating soup storage pot, a cold marinating soup storage pot, a cooling column and a spice cooking pot. The spice cooking pot for making marinating soup is connected with the hot marinating soup storage pot and the cold marinating soup storage pot, respectively; the hot marinating soup storage pot and the cold marinating soup storage pot are connected with the egg marinating pot, respectively; and the cooling column for cooling is connected with the cold marinating soup storage pot and an egg cooking pot, respectively. The invention also relates to a method for marinating eggs with hot marinating soup and cold marinating soup alternately. The device and method for marinating eggs disclosed in the invention have the advantages of time saving, quick absorption of marinating soup by eggs and high automation degree, are especially suitable for automatic production in large scale, and belong to the technical field of marinating egg processing.

Owner:广东无穷食品集团有限公司

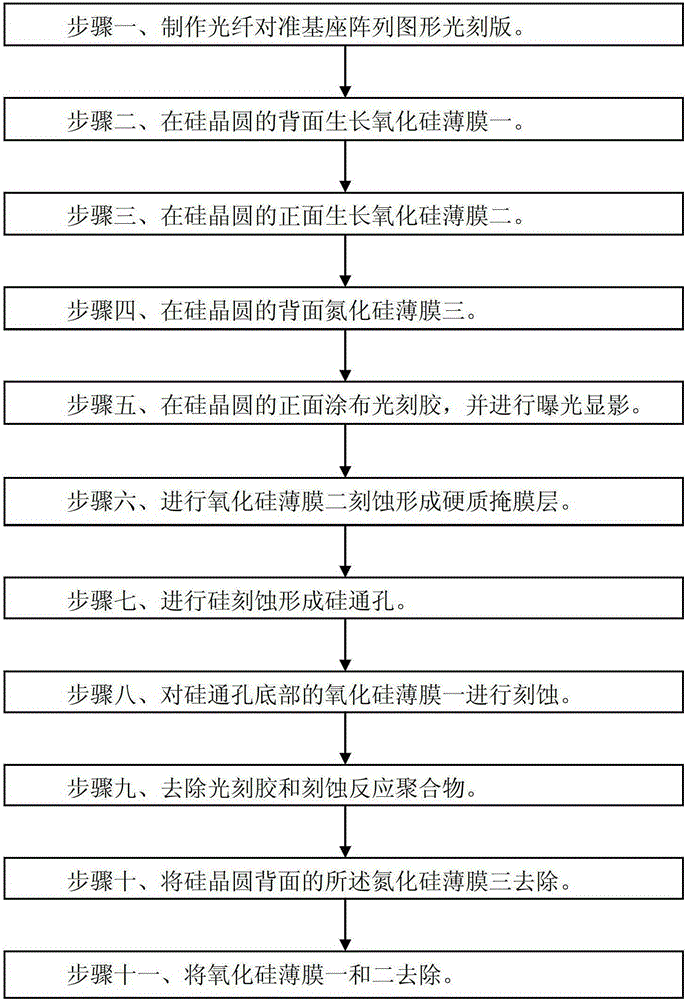

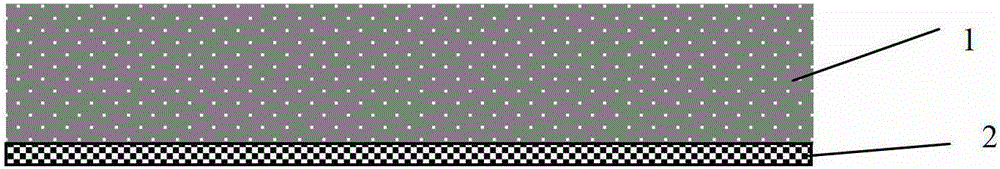

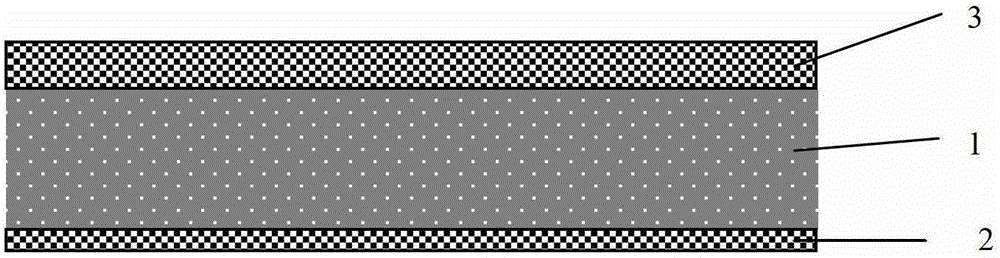

Fabrication method of fiber alignment pedestal array

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

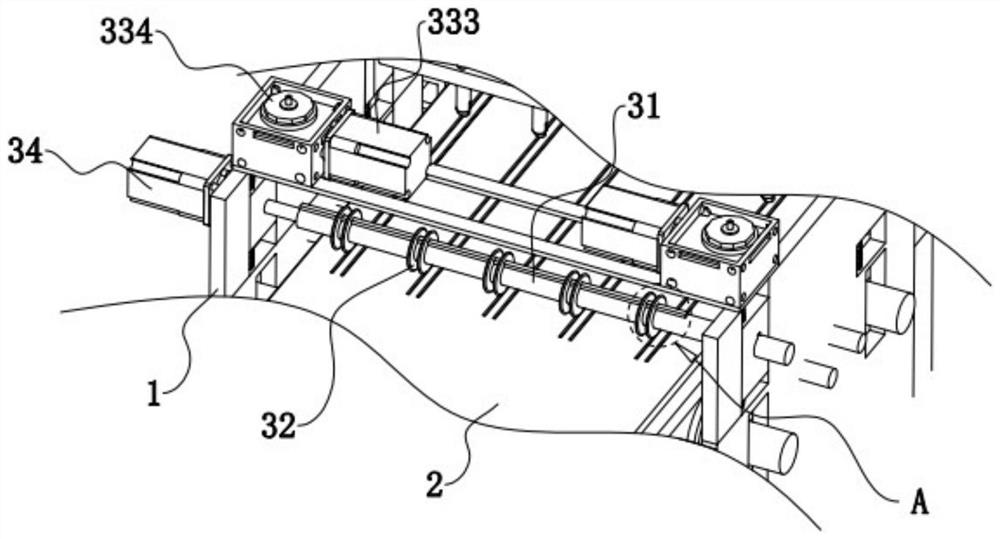

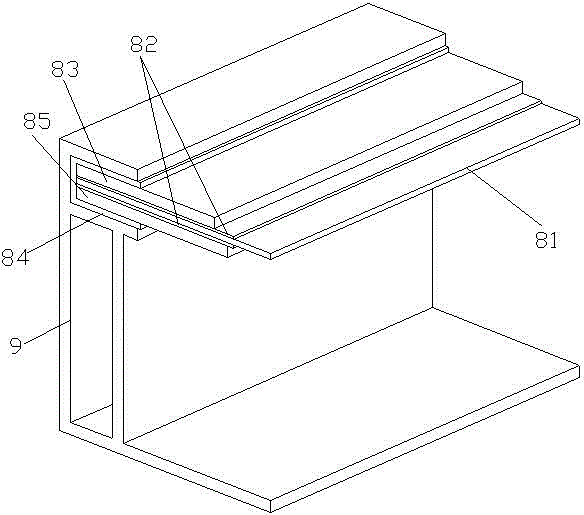

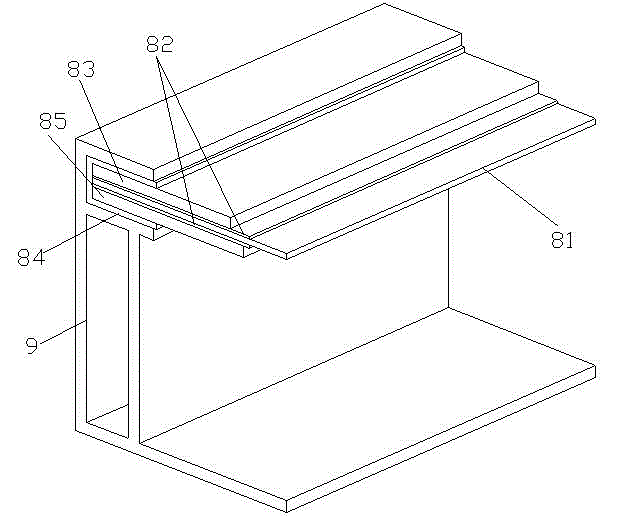

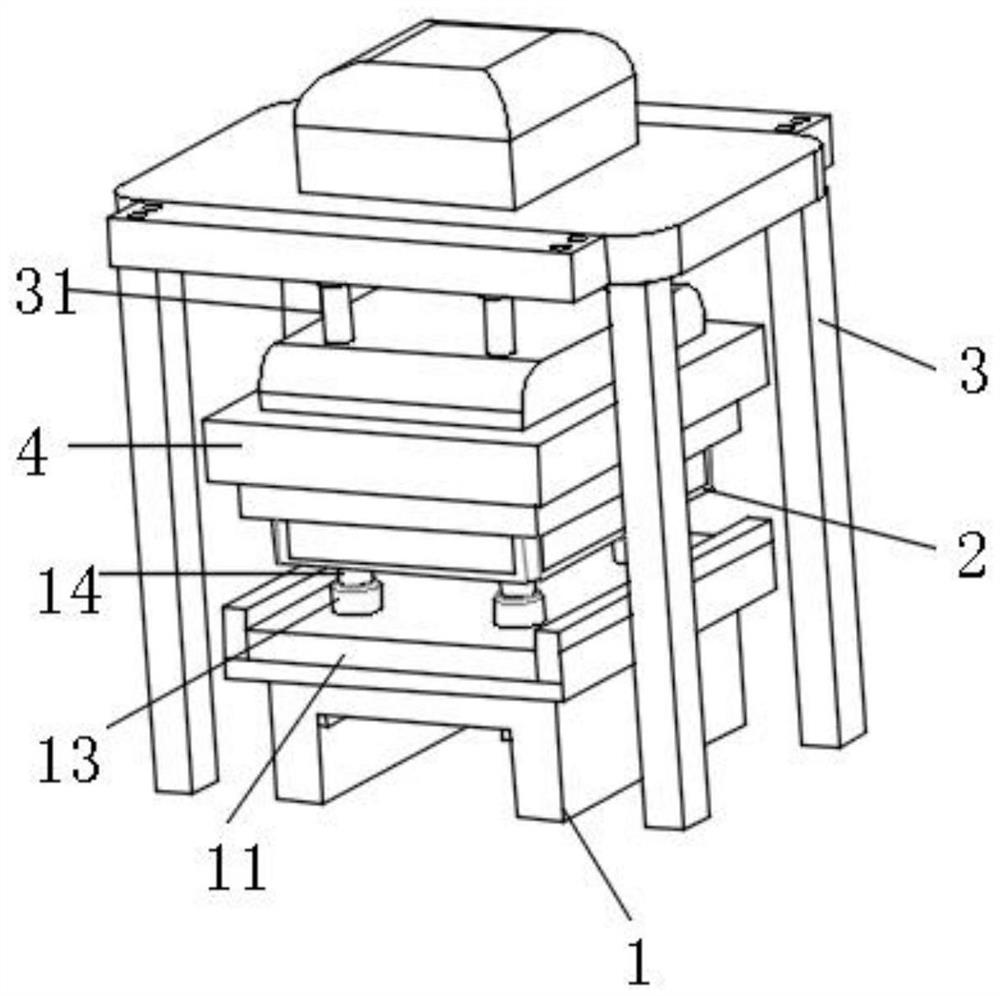

Heat sealing equipment and method for solar cell module

ActiveCN102983228BLow costImprove sealingFinal product manufactureSemiconductor devicesSolar moduleSolar energy

The invention relates to heat sealing equipment and a method for a solar cell module. The equipment is characterized in that the heat sealing equipment comprises at least one heat unit, wherein each heat unit comprises a conveying location mechanism positioned at the lower layer and extending transversely, an annular heat mechanism positioned at the upper layer, and a climbing mechanism arranged in the middle of the conveying location mechanism and the heat mechanism. The equipment and the method are high in heat sealing speed, convenient to operate, high in efficiency, and suitable for large-scale automatic production, a sealing material is low in cost and convenient to transport, the obtained solar cell module is good in sealing effect and long in service life, requirements of the solar cell module on long operation are completely met, and the production efficiency of the solar cell module manufacturing industry can be improved greatly. The heat sealing equipment can be used individually and used in a flow conveying line.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Solution automatic preparation device and powder dissolving method

ActiveCN105169978BDissolve evenlyEfficient and uniform dissolutionMixersDissolvingElectricityEngineering

The invention provides an automatic solution preparation device and a powder body dissolution device, and relates to the field of chemical engineering. The automatic solution preparation device comprises a feeding mechanism, a pre-dissolution mechanism, a first stirring mechanism, a second stirring mechanism, a liquid level controller, an electric control mechanism, a dissolution box, a curing box and a finished product box, wherein the dissolution box, the curing box and the finished product box are sequentially in adjacent arrangement; the feeding mechanism is communicated with the pre-dissolution mechanism; the pre-dissolution mechanism is communicated with the inside of the dissolution box; the pre-dissolution mechanism is provided with a liquid inlet pipe; the first stirring mechanism is arranged in the dissolution box; the second stirring mechanism is arranged in the curing box; the liquid level controller is arranged in the finished product box; the electric control mechanism is respectively and electrically connected with the feeding mechanism, the pre-dissolution mechanism, the first stirring mechanism, the second stirring mechanism, the liquid level controller and the liquid overflowing pipe. When the device and the method provided by the invention are adopted, the dissolution of solutes in solvents is very efficient and uniform; the linear dissolution can be effectively avoided; the quality of the solution can be ensured; meanwhile, the automation degree is high; the device and the method are suitable for mass automatic production.

Owner:临沂龙软企业管理咨询有限公司

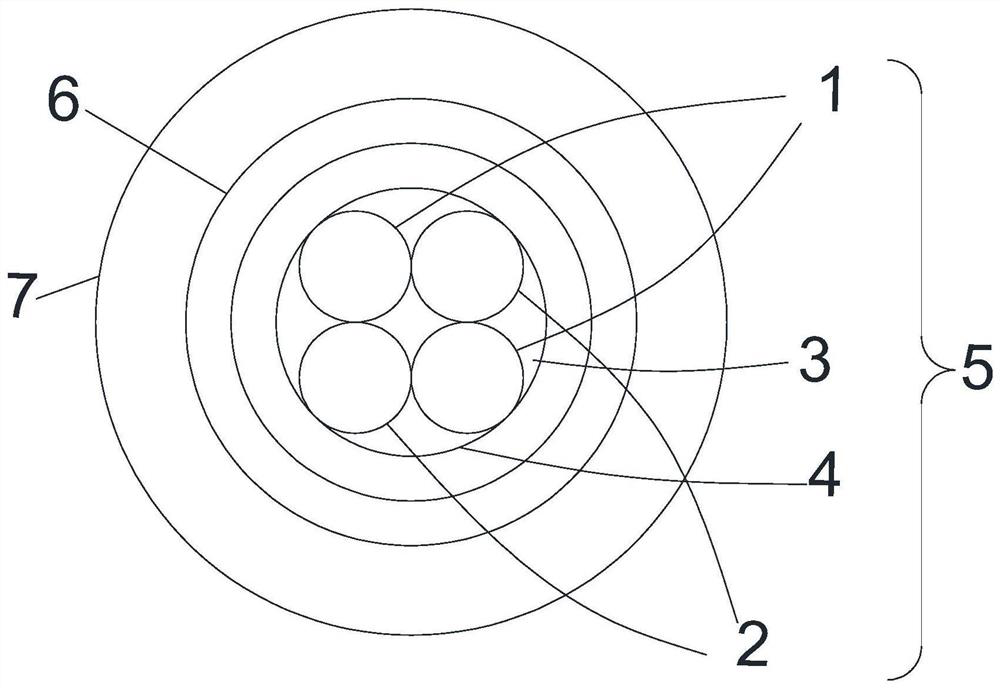

Carbon fiber heating wire for melting snow and ice on roads and bridges

PendingCN113329534AStrong corrosion and oxidation resistanceImprove stabilityHeating element shapesHeating element materialsCross-linked polyethyleneCarbon nanotube

The invention provides a carbon fiber heating wire for melting snow and ice on roads and bridges, which comprises an inner layer heating wire bundle, a carbon nano tube bucky paper glass fiber epoxy resin layer, a polytetrafluoroethylene layer, a crosslinked polyethylene layer and a stainless steel woven mesh sleeve which are sequentially wrapped from inside to outside. The inner layer heating wire bundle is used as an inner layer heating layer and consists of a plurality of carbon fiber heating wires; the carbon nano tube bucky paper glass fiber epoxy resin layer is used as a heat diffusion layer, the polytetrafluoroethylene layer is used as a middle layer, the crosslinked polyethylene layer is used as a secondary outer layer, and the stainless steel woven mesh sleeve is used as an outermost layer. Through the arrangement of the carbon fiber heating wire bundle, rapid heating, high electrothermal conversion efficiency, high tensile strength, light weight, stable chemical performance and long service life are realized, through the arrangement of the middle carbon nano tube bucky paper glass fiber epoxy resin layer, the overall heat transfer radius of the heating wire is enhanced, the heat loss in the outward heat transfer process of the heating wire is reduced, and rapid temperature rise, effective heat transfer, stability and durability can be ensured.

Owner:HUBEI UNIV OF TECH

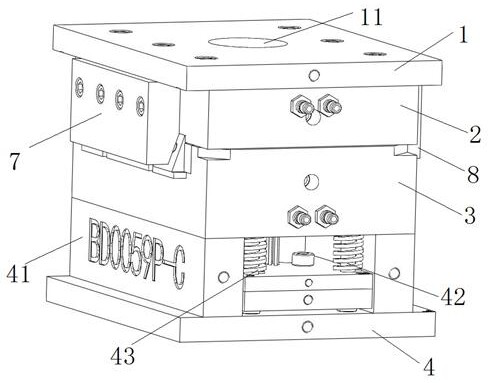

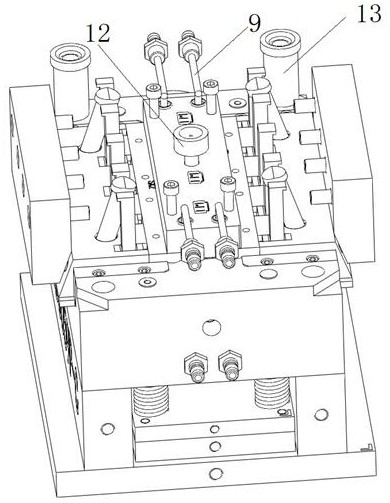

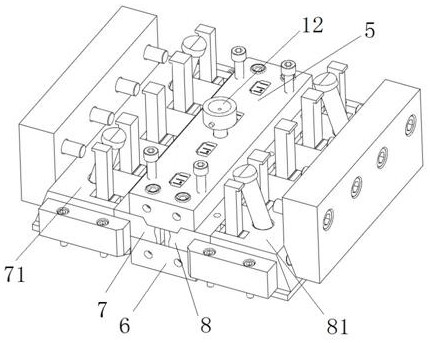

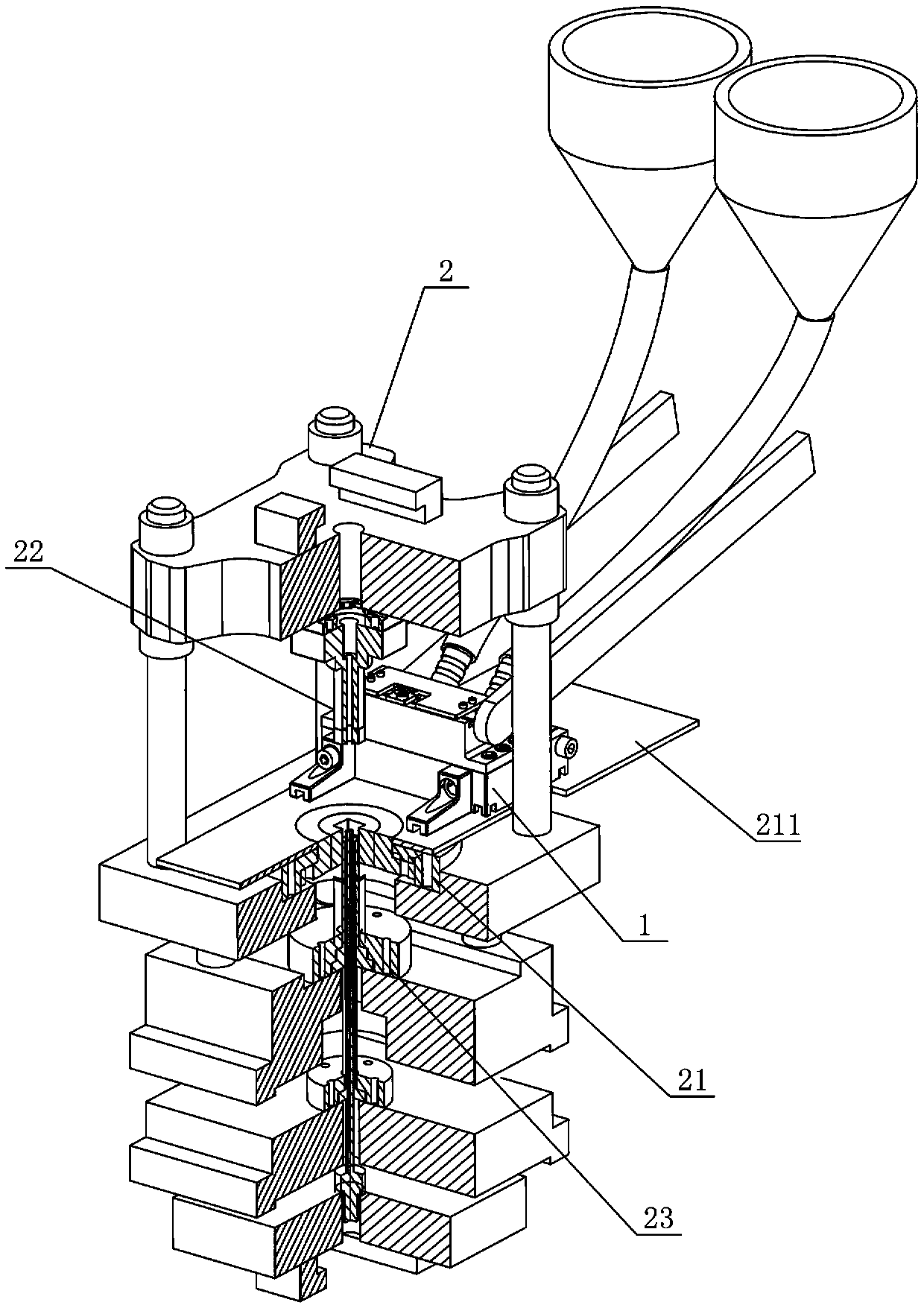

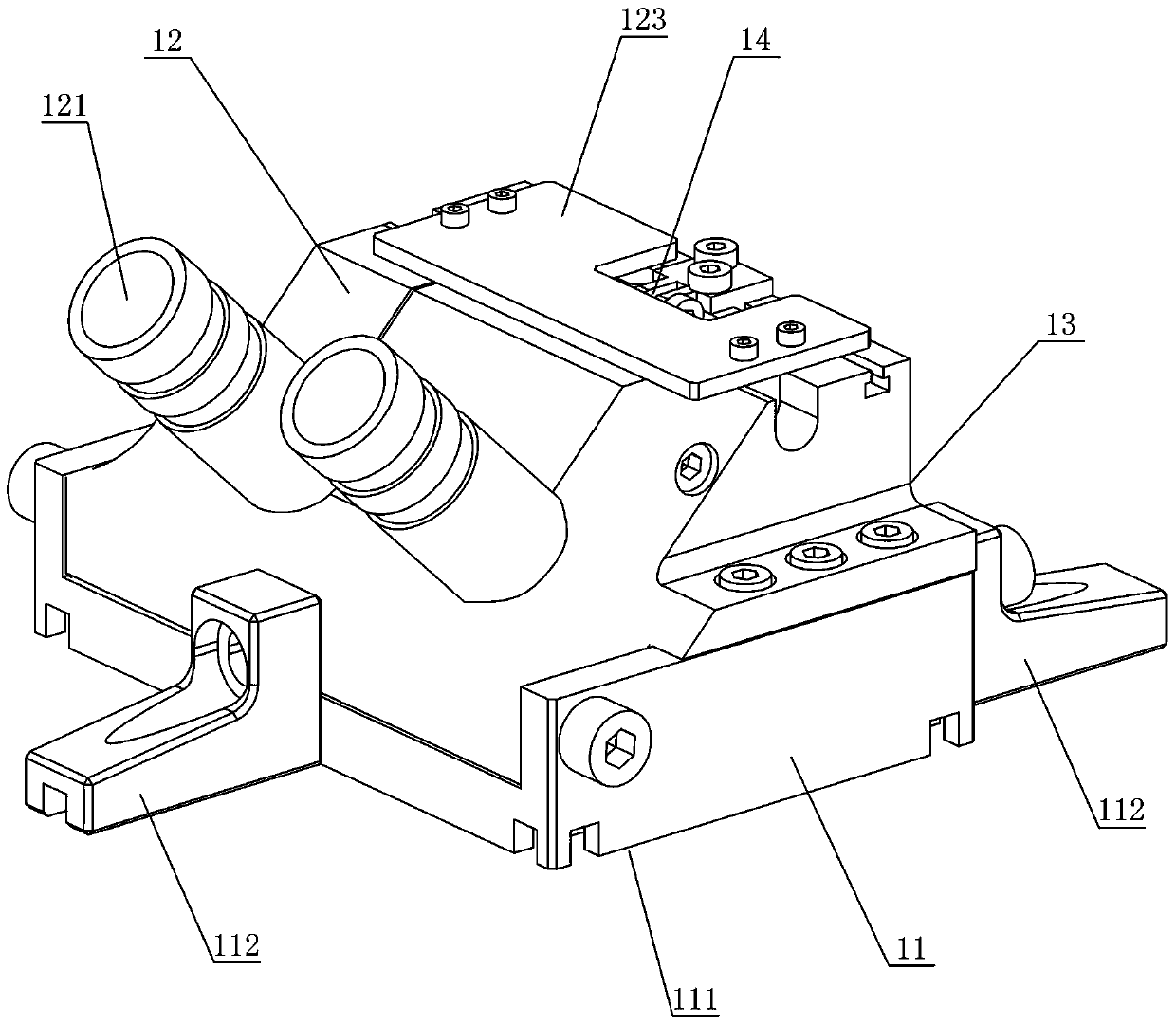

A molding device and molding method for powder metallurgy parts

The invention discloses a forming device and a forming method of powder metallurgy part. The forming device and the forming method of the powder metallurgy part comprise a feeding vessel and a formingmodule, wherein the feeding vessel comprises a base and a plurality of front sealing covers for selecting and mounting, a rear sealing cover and a plurality of separation plates, at least two feedingpipes are arranged on each front sealing cover; the number of the feeding pipes on each front sealing cover is different, a discharging hole is formed in the base, and the discharging hole is in buttjoint with the forming module; the front sealing cover is connected with the rear sealing cover and covers the top of the base, each feeding pipe of the front sealing cover extends into the discharging hole, and each separation plate is arranged on the inner wall of the rear sealing cover, and every two adjacent feeding pipes are separated by each separation plate. The method comprises the stepsof S1, mounting; S2, feeding; S3, pressing; S4, mold stripping; S5, sintering; and S6, circulating the steps from S2 to S5. The forming device and forming method of powder metallurgy part has the advantages of being simple in structure, convenient to operate,and high in forming efficiency and stability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

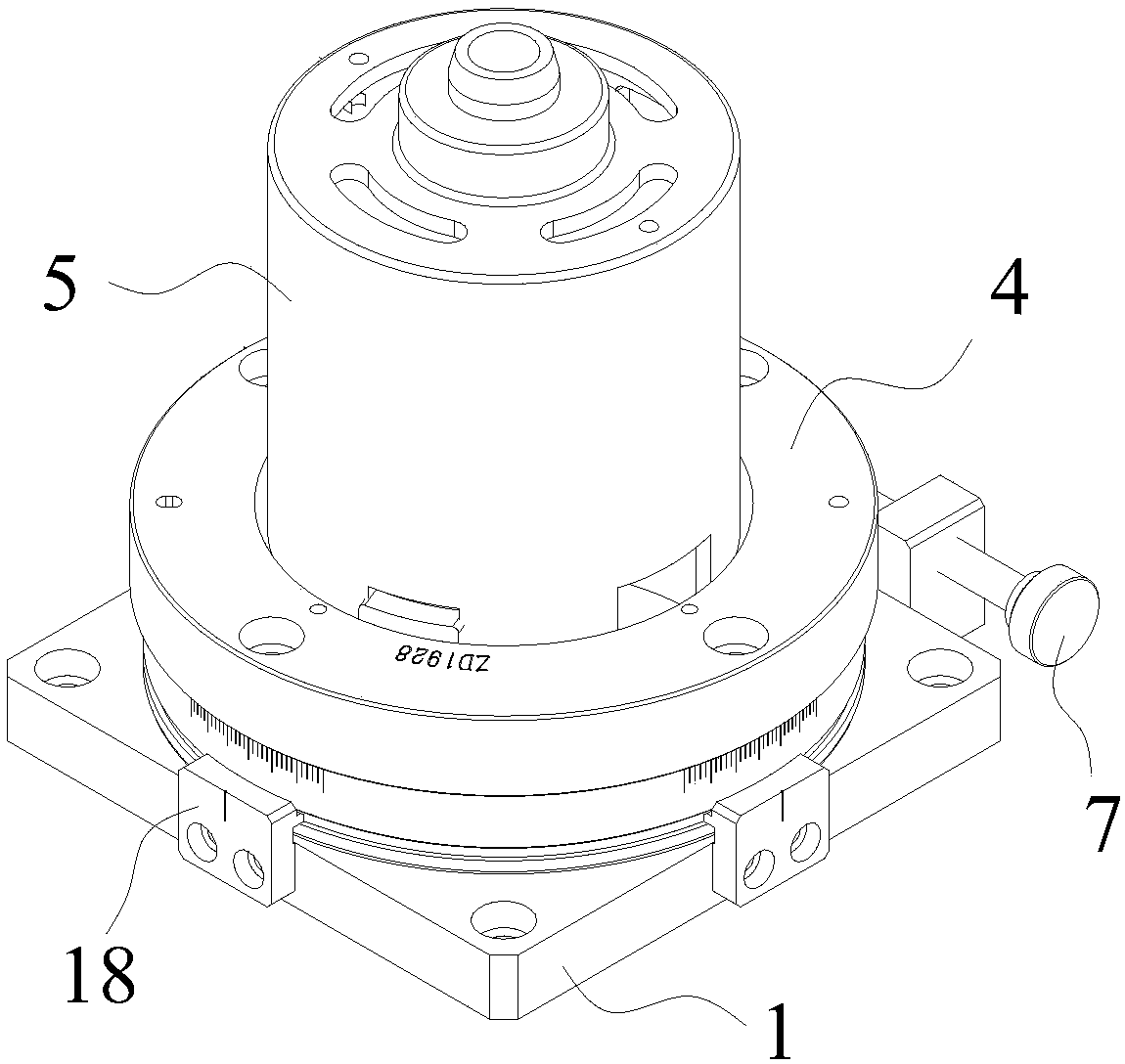

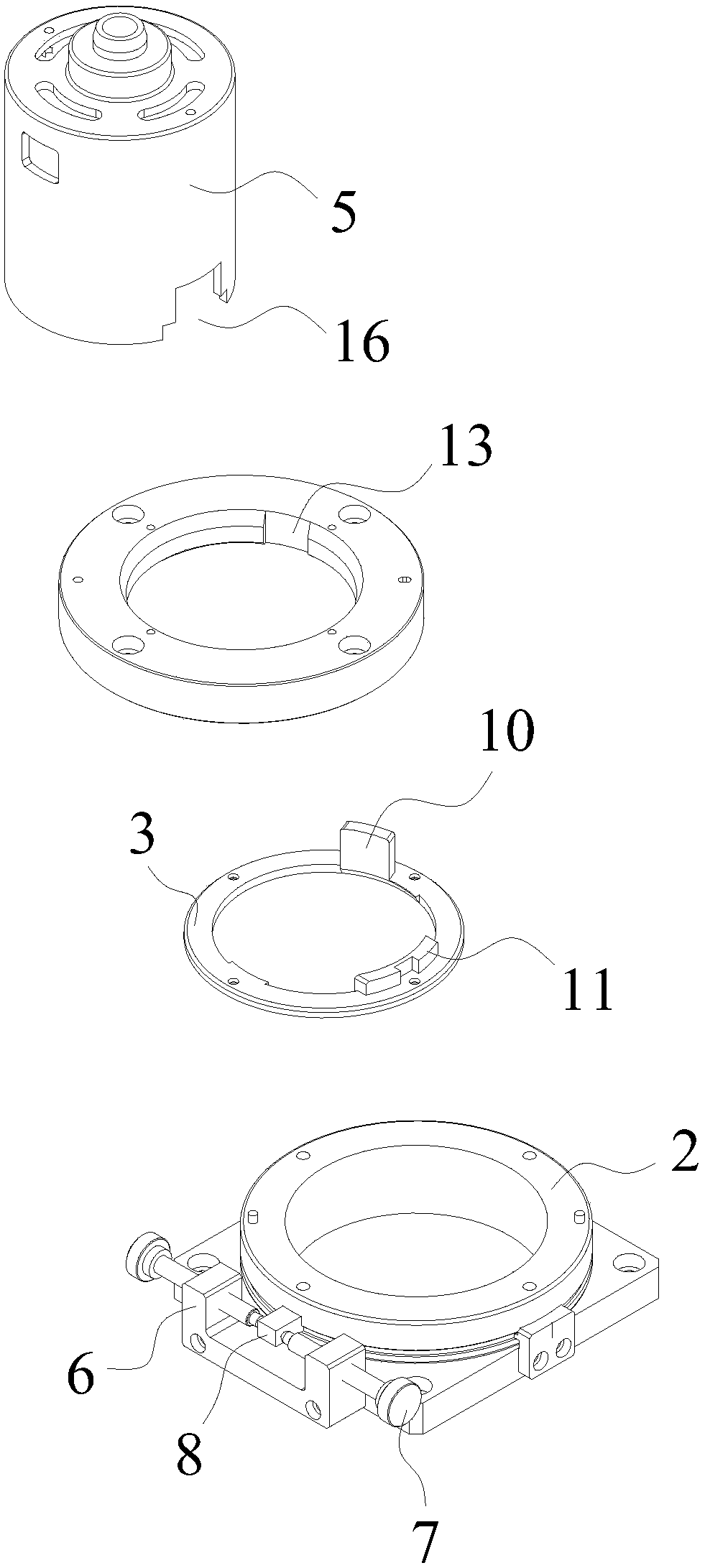

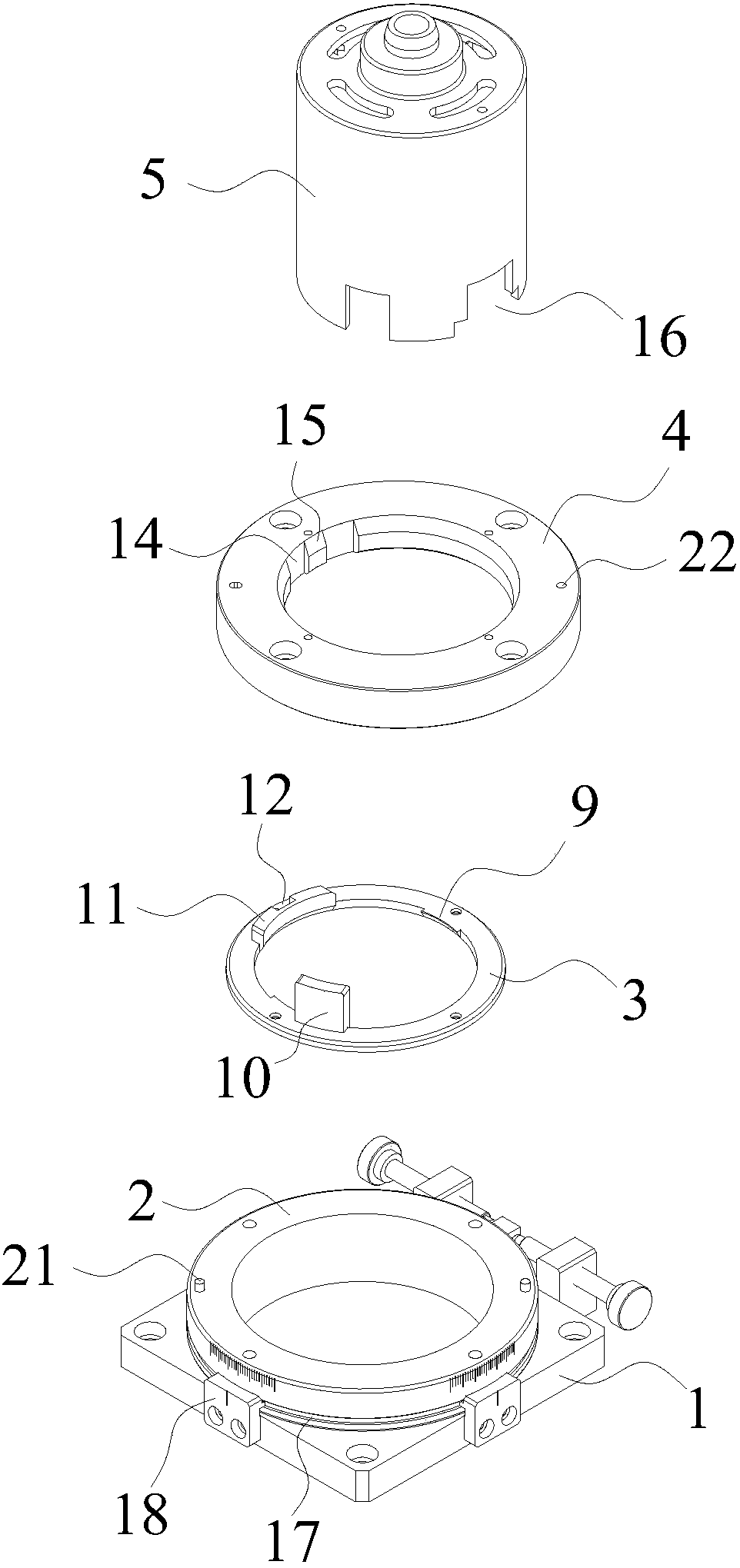

Case fixing device

PendingCN107819371AImprove positional stabilityFixed position is accurateMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringFixed position

The invention discloses a case fixing device, which comprises a positioning plate base, wherein the positioning plate base is provided with an annular fine-tuning rotating ring capable of rotating along the center on the positioning plate base; an annular positioning ring is fixed on the upper end surface of the fine-tuning rotating ring; the annular clamping and fixing ring is clamped and fixed on the positioning ring; and a case is clamped and fixed on an inner circle of the clamping and fixing ring. The case fixing device is good in case positioning stability and accurate in fixed position,and a magnetic shoe and the case are prompted to be laminated more closely.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

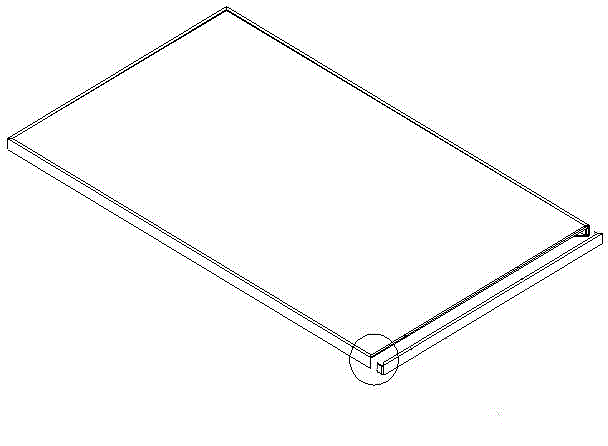

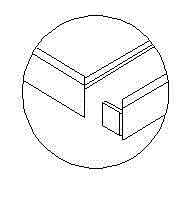

Steel waste acid and alkali liquor storage tank inner surface anticorrosion method

InactiveCN110370652AExcellent anti-acid and alkali corrosionGood seam sealing performanceSteel qualityCorrosion

The invention discloses a steel waste acid and alkali liquor storage tank inner surface anticorrosion method. The steel waste acid and alkali liquor storage tank inner surface anticorrosion method utilizes the advantage of being strong in acid and alkali corrosion resistance of ethylene, and prepares a thick ethylene coating on the inner surface of a tank body. The steel waste acid and alkali liquor storage tank inner surface anticorrosion method includes the concrete steps that in a preparation method of the side wall anticorrosion coating, an extrusion forming machine is used for forming ethylene plates through extrusion according to the curvature of the inner wall of the tank body, the thickness of the ethylene plates is confirmed according to requirements of a user for use life, and the thicker the ethylene plates are, the longer the use life is; an acid and alkali corrosion resisting bonding agent is used for bonding the reverse sides of the ethylene plates and the inner wall of the tank body; a pressure hot melting method is used for connecting side ends of the ethylene plates; and the bottom and the top of the tank body are planes, flat ethylene plates can be directly purchased and cut into squares or other shapes facilitating splicing, and similarly, the reverse sides of the flat ethylene plates after being cut are bonded with the inner wall of the tank body, and the pressure hot melting method is used on the side faces of the flat ethylene plates after being cut. Due to the fact that the pressure melting weld is adopted, a weld joint is good in seal performance; the construction technology is simple, energy consumption is low, and efficiency is high; and forming and connection of the ethylene plates are low in cost and high in efficiency, the ethylene plates are long in use life, reduction of repair frequency and cost of a waste acid and alkali liquor storage tank is facilitated, and economic benefit of an enterprise is improved.

Owner:JIANGSU KEHUAN INNOVATIVE MATERIAL CO LTD +1

Heat sealing equipment and method for solar cell module

ActiveCN102983228ALow costImprove sealingFinal product manufactureSemiconductor devicesSolar moduleSolar energy

The invention relates to heat sealing equipment and a method for a solar cell module. The equipment is characterized in that the heat sealing equipment comprises at least one heat unit, wherein each heat unit comprises a conveying location mechanism positioned at the lower layer and extending transversely, an annular heat mechanism positioned at the upper layer, and a climbing mechanism arranged in the middle of the conveying location mechanism and the heat mechanism. The equipment and the method are high in heat sealing speed, convenient to operate, high in efficiency, and suitable for large-scale automatic production, a sealing material is low in cost and convenient to transport, the obtained solar cell module is good in sealing effect and long in service life, requirements of the solar cell module on long operation are completely met, and the production efficiency of the solar cell module manufacturing industry can be improved greatly. The heat sealing equipment can be used individually and used in a flow conveying line.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Anti-compression cable for melting snow and ice on road and bridge

PendingCN114121353AImprove closing effectImprove tensile propertiesPower cables with screens/conductive layersInsulated cablesCopper wireStructural engineering

The invention discloses a road and bridge anti-compression cable for melting snow and ice. The cable comprises a cable body wrapping group, a crosslinked polyethylene layer and a stainless steel woven mesh sleeve layer, wherein the crosslinked polyethylene layer is used as an outer wrapping layer, and the stainless steel woven mesh sleeve layer is used as an armor layer and sequentially wraps the cable body wrapping group from inside to outside; the cable body package is composed of two internal copper wire conductive layers, two tensile cables and a compression-resistant insulating flame-retardant layer wrapping the internal copper wire conductive layers and the tensile cables, compression-resistant insulating flame-retardant filler is filled among the internal copper wire conductive layers, the tensile cables and the compression-resistant insulating flame-retardant layer, and the number of the internal copper wire conductive layers and the number of the tensile cables are both two. And the internal copper wire conductive layers and the tensile cables are distributed in a staggered manner. Wherein the tensile cable is used as a main tensile resistance source of the cable and is composed of a plurality of basalt fibers; the crosslinked polyethylene layer is used as an outer cladding layer, and the stainless steel woven mesh sleeve is used as an armor layer. By arranging the cable body package group, the overall closing performance of the cable is improved, the overall tensile, compression-resistant, wear-resistant and waterproof performance of the cable body is enhanced, the chemical performance of the cable is stable, and the service life of the cable is prolonged.

Owner:HUBEI UNIV OF TECH

Induction sealing method for solar component

ActiveCN102916072BLow costMeet long working hoursFinal product manufactureSemiconductor devicesEngineeringElectrical and Electronics engineering

The invention provides an induction sealing method for a solar component. According to the induction sealing method, the solar component provided with a frame, sealing material and a solar laminated panel is arranged under an induction sealing head, the aluminum frame generates induction current inside under the action of the magnetic field of the sealing head, then the electric energy is converted into heat energy, the sealing material is gradually heated under the action of the heat energy to wrap and adhere the edge of the solar laminated panel and a groove of the aluminum frame and fill the gap between the edge of the solar laminated panel and the groove of the aluminum frame, so that the sealing effect is played. According to the induction sealing method specially designed for the solar component, the technology is simple, the sealing method is safe and environment-friendly, the sealing time is short, and the encapsulation effect for the solar component is superior.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Laminated slab processing equipment

PendingCN113580328AReduce prone to cracksReduce defective rateShaping press ramElectric machineryBuilding material

The invention provides laminated slab processing equipment, and relates to the field of building materials. The laminated slab processing equipment comprises a fixing table, a mounting frame, a fixing frame, a mounting box, an embedding plate, an adjusting plate and a forming pipe, and is characterized in that a conveying belt is arranged on the outer wall of the top end of the fixing table, a vibration motor is fixedly connected to the outer wall of the top end of the conveying belt, and a supporting ring is fixedly connected to the outer wall of the top end of the vibration motor; the mounting frame is arranged on the outer wall of the top end of the supporting ring, the mounting frame is connected with the embedding plate in an inserted manner, clamping plates distributed at equal intervals are arranged on the outer wall of the bottom end of the adjusting plate, the embedding plate is movably connected with the adjusting plate, and a fixing mechanism is arranged between the mounting frame and the adjusting plate. According to the laminated slab processing equipment, the bottom end of a laminated slab is more compact, the problem that the bottom of the laminated slab is likely to crack in automatic production is solved, and the defective rate is reduced.

Owner:阜阳市晶宫工业科技有限公司

Plastic part injection molding production forming method

The invention provides a plastic part injection molding production forming method. A forming mold is included and comprises a top plate, an upper mold plate, a lower mold plate and a bottom plate which are sequentially arranged. A first mold groove is formed in the upper mold plate and internally provided with a first mold. A second mold groove is formed in the lower mold plate and internally provided with a second mold. The first mold and the second mold are correspondingly arranged. A third mold and a fourth mold are symmetrically arranged between the first mold and the second mold. The third mold is connected with a first side drive block, and the fourth mold is connected with a second side drive block. The first mold, the second mold, the third mold and the fourth mold are correspondingly arranged in a matched manner. According to the plastic part injection molding production forming method, automatic machining of injection molding inserts can be achieved, the produced injection molding inserts in specific shapes are uniform in thickness, the injection molding machining precision is high, the product yield is high, rapid demolding can be achieved, the production efficiency is high, the product meets the requirement of the industry standard, and the plastic part injection molding production forming method is suitable for large-scale automatic production.

Owner:惠州上记塑胶五金制品有限公司

A kind of environment-friendly fluorescent ink and preparation method thereof

The invention provides environment-friendly fluorescent printing ink and a preparation method thereof. The fluorescent printing ink comprises the following components by weight percent: 0.1%-4% of a fluorescent pigment, 30%-60% of an acrylic emulsion, 0.2%-5% of a wear-resistant aid, 0.1%-1% of a de-foaming agent, 1%-5% of a film-forming agent, 15%-30% of ethanol and 15%-30% of water. Compared with an existing solvent type fluorescent printing ink, the fluorescent printing ink provided by the invention has the advantages that fluorescent color is bright, the dispersity is good, and no color migration is caused; the heat resistance is good, so that high temperature of 600 DEG C can be resisted; the water and ethanol are used as dissolving carriers, so that the ink is nontoxic, non-combustible, non-explosive and free of volatile organic gas; material components are simple and the cost is low.

Owner:哈尔滨绿科科技有限公司

Forming device and forming method of powder metallurgy part

The invention discloses a forming device and a forming method of powder metallurgy part. The forming device and the forming method of the powder metallurgy part comprise a feeding vessel and a formingmodule, wherein the feeding vessel comprises a base and a plurality of front sealing covers for selecting and mounting, a rear sealing cover and a plurality of separation plates, at least two feedingpipes are arranged on each front sealing cover; the number of the feeding pipes on each front sealing cover is different, a discharging hole is formed in the base, and the discharging hole is in buttjoint with the forming module; the front sealing cover is connected with the rear sealing cover and covers the top of the base, each feeding pipe of the front sealing cover extends into the discharging hole, and each separation plate is arranged on the inner wall of the rear sealing cover, and every two adjacent feeding pipes are separated by each separation plate. The method comprises the stepsof S1, mounting; S2, feeding; S3, pressing; S4, mold stripping; S5, sintering; and S6, circulating the steps from S2 to S5. The forming device and forming method of powder metallurgy part has the advantages of being simple in structure, convenient to operate,and high in forming efficiency and stability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Thermal protection element and manufacturing method thereof

ActiveCN104112626BSimple structureSuitable for large-scale automated productionThermal switch detailsEngineeringSurface-mount technology

The invention discloses a thermoelectric protection element and a manufacturing method thereof. The thermoelectric protection element comprises a heating element, an insulated shell and an upper cover plate sequentially stacked from the bottom top, wherein the bottom surface of the heating element is provided with a first left electrode and a first right electrode; the top surface of the heating element is provided with a second left electrode and a second right electrode; the bottom surface of the upper cover plate is provided with a third left electrode and a third right electrode; the insulated shell is internally provided with a first cavity; the fixed end of a thermal drive switch is clamped between the bottom surface of the insulated shell and the second left electrode; and the moving end of the thermal drive switch is located inside the cavity of the insulated shell and is electrically contacted with the third right electrode in a normal state. The thermoelectric protection element also comprises a first left pad, a first right pad, a second left pad, a second right pad, a left-end electrode and a right-end electrode. According to the thermoelectric protection element, the structure is simple, large-scale automatic production is facilitated, the manufacturing cost is low, the element area is small, space is saved, and the thermoelectric protection element can be applied to the integrated circuit surface-mount technology.

Owner:上海神沃电子有限公司

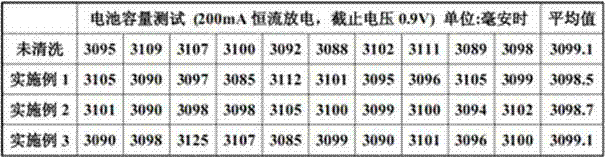

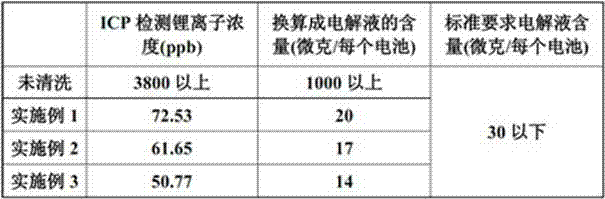

Method for cleaning sealed lithium-ferrous disulfide battery

ActiveCN102179380BImprove surface cleanlinessIncrease productivityDrying solid materials with heatCleaning using liquidsElectrical batteryMegasonic cleaning

The invention provides a method for cleaning a sealed lithium-ferrous disulfide battery, and the method comprises the following steps: an ultrasonic cleaning step: keeping the battery at a state of being completely soaked in a cleaning fluid and ultrasonically cleaning the battery in the cleaning fluid; a pure water spraying step: spraying the ultrasonically cleaned battery with pure water; and adrying step: blow-drying the sprayed battery, wherein the cleaning fluid is pure water or a mixed liquid formed by adding a non-conductive cleaning fluid into the pure water; the conductivity of the cleaning fluid is less than 20 microseconds per centimeter; and the conductivity is a value measured at the use temperature of the cleaning fluid. By using the cleaning method provided by the invention, the electrolytes and greasy dirt in the bound area and sealed area of the battery and at the micro-pore gap of the electroplated layer of the battery can be removed and the surface cleanness of battery can be greatly improved.

Owner:FUJIAN NANPING NANFU BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com