Micro thermocouple threading device and machining method

A thermocouple wire and thermocouple technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low quality thermocouple products, low work efficiency, high work intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

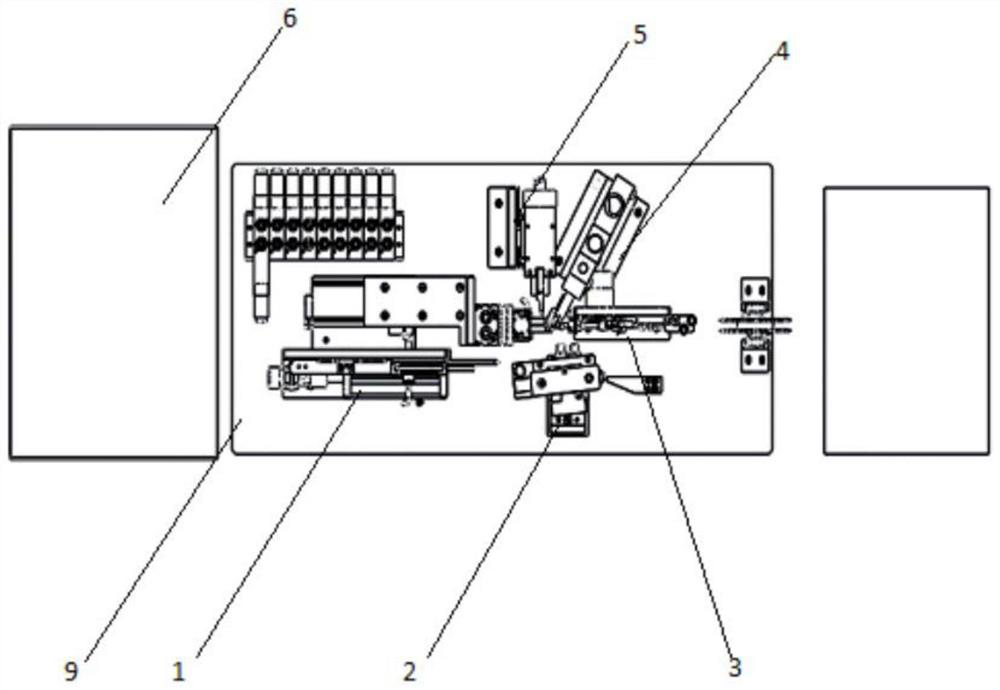

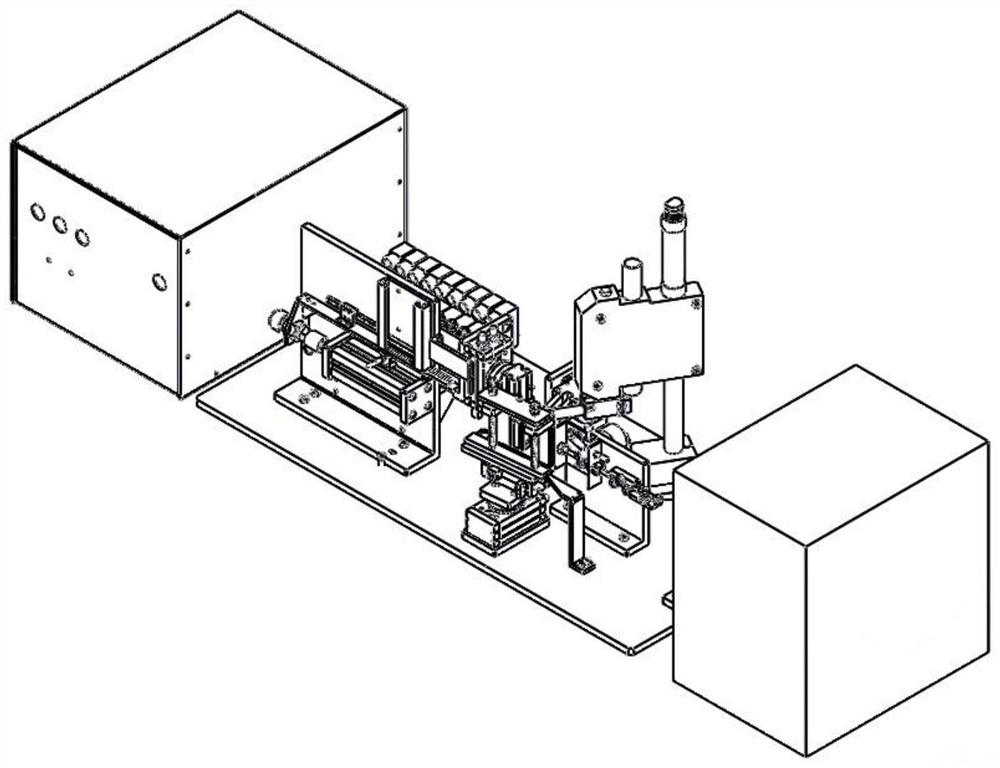

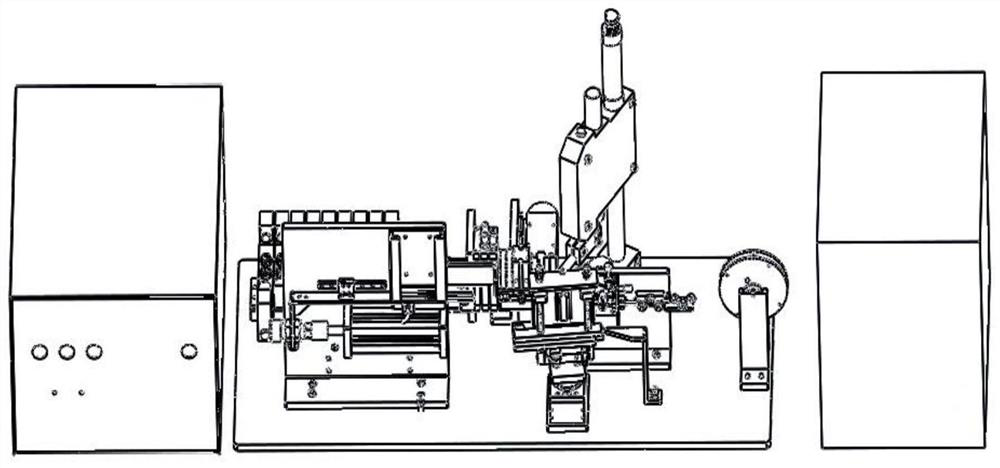

[0065] This embodiment provides a processing method for a thermocouple wire threading device, including a storage and feeding mechanism 1, a thermocouple wire clamping mechanism 2, a wire feeding mechanism 3, a welding mechanism 4, a shearing mechanism 5, a control box 6 and a processing platform 9 , specifically including the following steps:

[0066] S100, place the U-shaped quartz long tube in the material storage mechanism 11, draw out the drawing wire from the drawing wire reel 33, and place it at the initial position of the wire feeding mechanism 3; check the power status of the equipment with a pneumatic power switch; the operator will Adjust the control box 6 knob to automatic mode and step on the foot switch, put the thermocouple wire into the thermocouple wire clamping mechanism 2 with tweezers, release the foot pedal to clamp the thermocouple wire after the comparison is completed.

[0067] S200, the pusher 121 pushes the U-shaped quartz long tube into the clamper 1...

Embodiment 2

[0076] This embodiment provides a processing method for a thermocouple wire threading device, including a storage and feeding mechanism 1, a wire feeding mechanism 3, a welding mechanism 4, a shearing mechanism 5, a control box 6 and a processing platform 9, and also includes two different The thermocouple sending welding mechanism of the thermocouple wire welding specifically includes the following steps:

[0077] S100, place the U-shaped long quartz tube in the material storage mechanism 11, draw out the drawing wire from the drawing wire tray, and place it at the starting position of the wire feeding mechanism 3; turn on the power switch, and check the power-on state of the equipment.

[0078] S200, the operator adjusts the 6 knob of the control box to the automatic mode and steps on the foot switch, the thermocouple sending and welding mechanism welds two different thermocouples, cuts, the robotic arm clamps the thermocouple, and detects the quality of the solder joints. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com