Ink capable of realizing cursor invisibility as well as preparation process and application of ink

An ink, invisible technology, applied in the direction of ink, application, rigid/semi-rigid container manufacturing, etc., can solve the problems of inability to put into practical application, insufficient fluorescence intensity, failure of photoelectric tracking, etc. The method is simple, the fluorescence intensity is high, and the difficulty subsidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

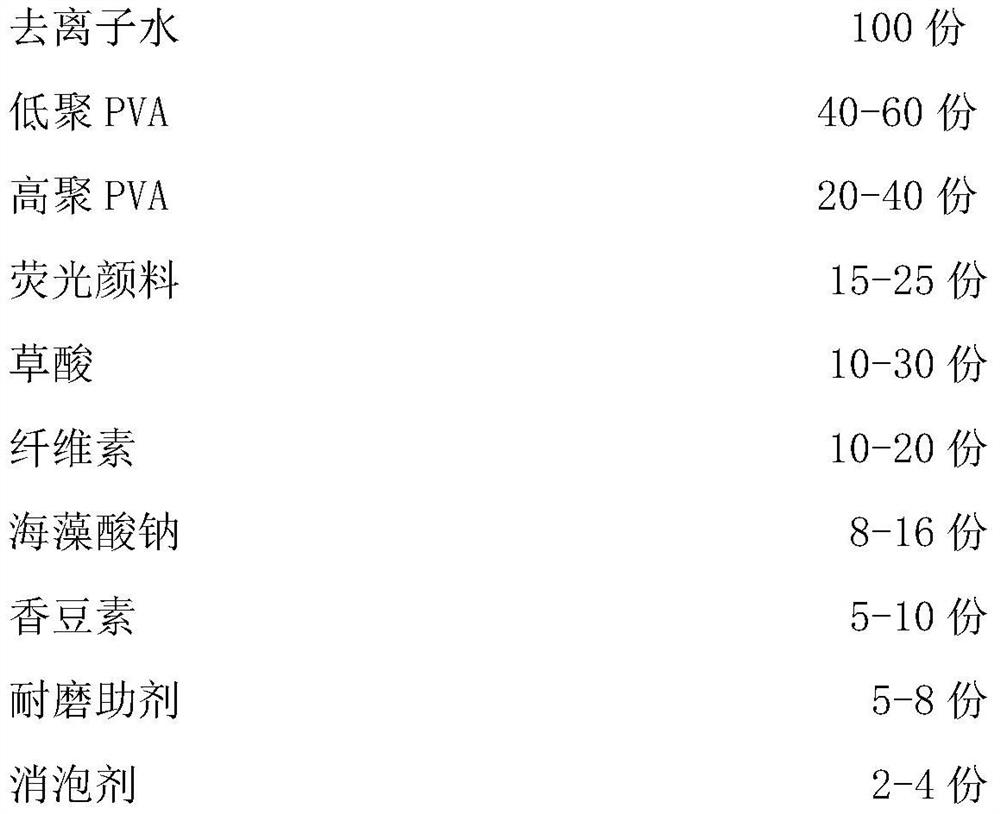

[0039] A kind of ink that realizes invisible cursor, described ink is made of the raw material of following weight part:

[0040]

[0041] The fluorescent pigment is an ultraviolet fluorescent pigment;

[0042] The average molecular weight of the PVA in the oligomeric PVA is 15000;

[0043] The average molecular weight of the PVA in the high poly PVA is 150000;

[0044] The ultraviolet fluorescent pigment is an inorganic ultraviolet fluorescent powder, purchased from Yao Dexing Technology;

[0045] The anti-wear additive is polyethylene wax;

[0046] Described defoamer is polyether modified silicone oil;

[0047] The above-mentioned preparation method of the ink for realizing the invisible cursor comprises the following steps:

[0048] Add fluorescent pigments, oligomeric PVA and oxalic acid to deionized water in turn under stirring conditions in S1 to form a mixed solution;

[0049] Under the stirring condition of S2, high poly PVA, oxalic acid, cellulose, sodium algi...

Embodiment 2

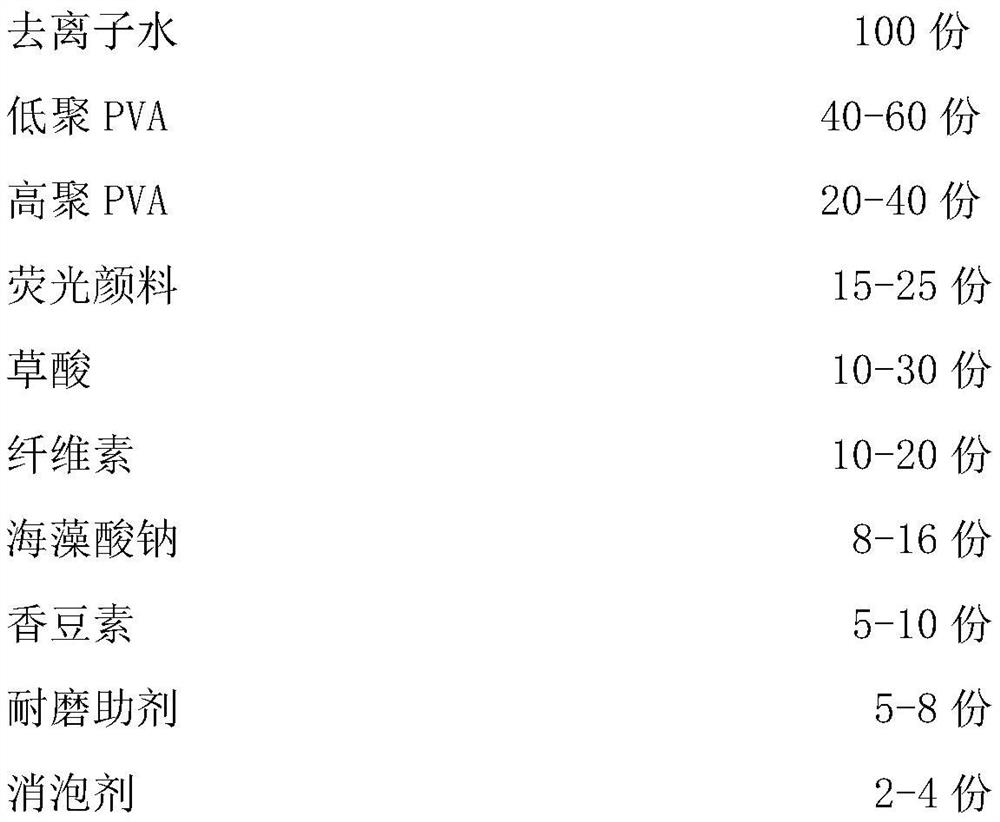

[0051] A kind of ink that realizes invisible cursor, described ink is made of the raw material of following weight part:

[0052]

[0053]

[0054] The fluorescent pigment is an ultraviolet fluorescent pigment;

[0055] The average molecular weight of the PVA in the oligomeric PVA is 18000;

[0056] The average molecular weight of the PVA in the high poly PVA is 180000;

[0057] The ultraviolet fluorescent pigment is an inorganic ultraviolet fluorescent powder, purchased from Yao Dexing Technology;

[0058] The anti-wear additive is polyethylene wax;

[0059] Described defoamer is polyether modified silicone oil;

[0060] The above-mentioned preparation method of the ink for realizing the invisible cursor comprises the following steps:

[0061] Add fluorescent pigments, oligomeric PVA and oxalic acid to deionized water in turn under stirring conditions in S1 to form a mixed solution;

[0062] Under the stirring condition of S2, high poly PVA, oxalic acid, cellulose, s...

Embodiment 3

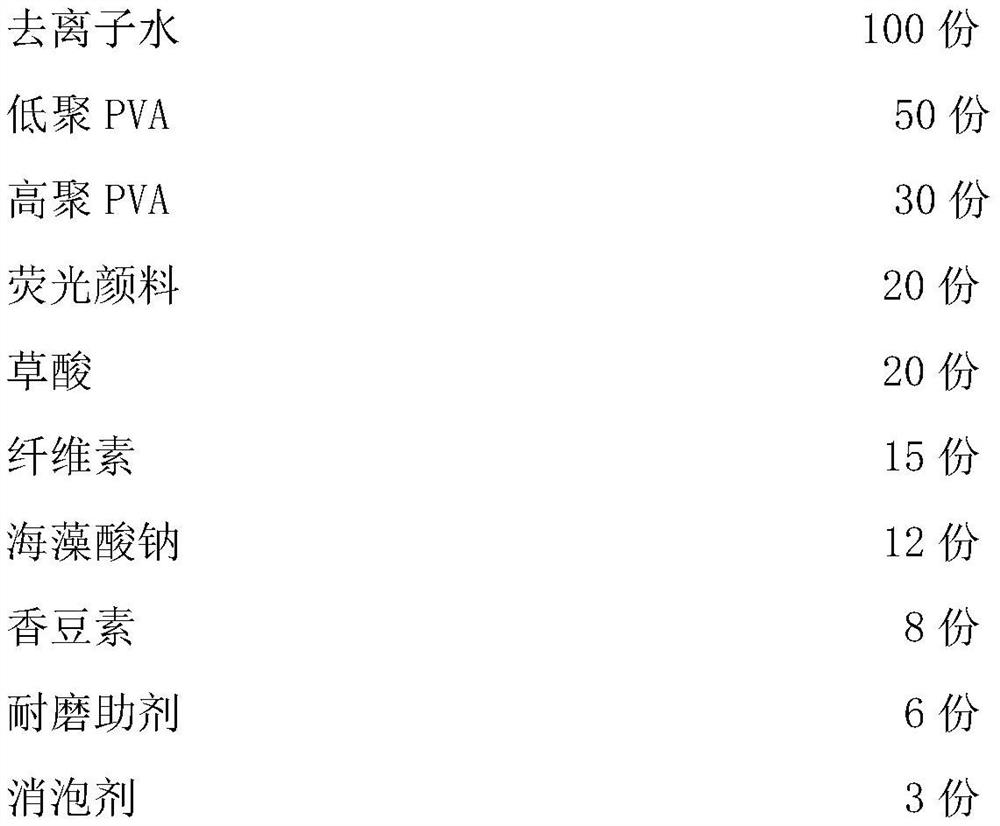

[0064] A kind of ink that realizes invisible cursor, described ink is made of the raw material of following weight part:

[0065]

[0066]

[0067] The fluorescent pigment is an ultraviolet fluorescent pigment;

[0068] The average molecular weight of the PVA in the oligomeric PVA is 20000;

[0069] The average molecular weight of the PVA in the high poly PVA is 200000;

[0070] The ultraviolet fluorescent pigment is an inorganic ultraviolet fluorescent powder, purchased from Yao Dexing Technology;

[0071] The anti-wear additive is polyethylene wax;

[0072] Described defoamer is polyether modified silicone oil;

[0073] The above-mentioned preparation method of the ink for realizing the invisible cursor comprises the following steps:

[0074] Add fluorescent pigments, oligomeric PVA and oxalic acid to deionized water in turn under stirring conditions in S1 to form a mixed solution;

[0075] Under the stirring condition of S2, high poly PVA, oxalic acid, cellulose,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com