Plastic part injection molding production forming method

A molding method and technology of plastic parts, which are applied in the field of injection molding of plastic parts, can solve the problems of unfavorable product yield rate, production efficiency improvement, uneven product thickness, low shape precision, etc., and achieve high product yield rate and injection molding processing accuracy High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

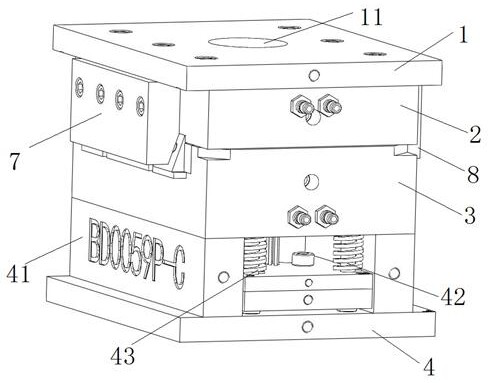

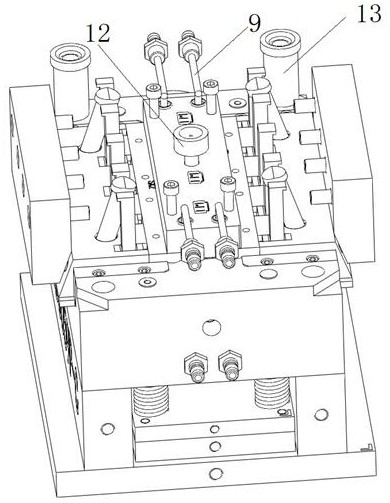

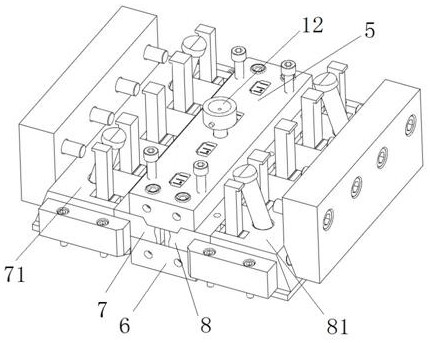

[0040] A kind of injection molding production molding method of plastic parts, is characterized in that, comprises forming mold, comprises the following steps:

[0041] Injection molding: first pour the molten plastic from the feed hopper, and the plastic that enters the feed hopper continues to flow down, and then enters the first mold, the second mold, the third mold, and the fourth mold to correct the gaps in between. The gap is filled, and at the same time, the temperature control pipe will heat or cool the first mold and the second mold respectively according to the actual processing conditions, so as to form injection molded parts of a specific shape with uniform thickness;

[0042] Demoulding: Lift the top plate, and then pass the connecting column to lift the upper template and the lower template in turn, and the lower template is bounced under the action of the demoulding spring, so that the first mold and the second lower mold are withdrawn from the lower template, E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com