Method for cleaning sealed lithium-ferrous disulfide battery

An iron disulfide battery and battery technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of reducing battery electrical performance, battery macula, high conductance requirements, etc., to improve production Efficiency, improved surface cleanliness, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0034] The batteries used in the embodiments of the present invention are all AA batteries, and the preparation method is as follows:

[0035] FeS 2 The powder (natural pyrite collected from Yunfu, Guangdong) is used as the positive electrode active material, and the material is mixed with the conductive agent (graphite and acetylene black) to make the positive electrode powder. Use an organic solvent to make the adhesive into an adhesive, wherein the adhesive is styrene-ethylene / butylene-styrene block copolymer (SEBS, trade name Kraton G1651), and the organic solvent is produced by Shell A mixture of Shell A100 (aromatic solvent) and Shell OMS (isoparaffin), the mixing ratio is 4:6 (weight ratio).

[0036] The above positive electrode powder and binder are mixed in a weight ratio of 2:1 and then stirred to form a slurry. In the dry matter of the positive electrode slurry finally made, the weight ratio of each component is:

[0037] FeS 2 : 91% by weight; graphite: 6% by w...

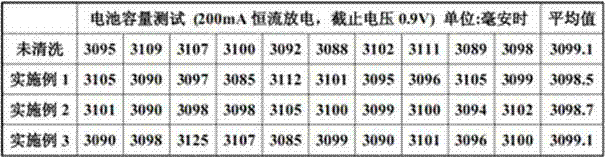

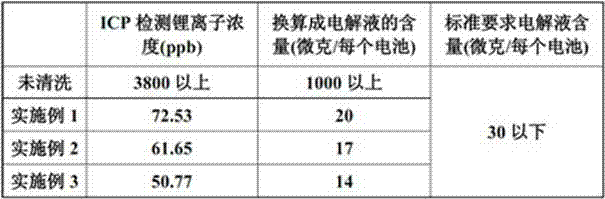

Embodiment 1

[0044] Take the 20 batteries obtained in the above preparation example and place them on the positioning tray, put them into a cleaning tank with ultrasonic waves, and add pure water with a temperature of 20°C and a conductivity of about 15 μs / cm. The liquid level of the pure water should be higher than Battery, so that the battery can be completely immersed in pure water, turn on the ultrasonic cleaning battery for 5 minutes (frequency is 40KHz, power is 0.5KW), then take out the battery, use a 3kg pressure pure water gun to clean the battery with pure water at 20°C (spray temperature) (Conductivity is about 8μs / cm) Spray all parts of the battery for 4 minutes, then use hot air (pressure 3kg, temperature about 50°C) to dry the moisture on the surface of the battery for 3 minutes, and the cleaned battery is obtained.

Embodiment 2

[0046] Take the 20 batteries obtained in the above preparation example and put them on the positioning tray, put them into a cleaning tank with ultrasonic waves, and add pure water with a temperature of 30°C and a conductivity of about 5 μs / cm. The liquid level of the pure water should be higher than Battery, so that the battery can be completely immersed in pure water, turn on the ultrasonic cleaning battery for 3 minutes (frequency is 120KHz, power is 3.5KW), then take out the battery, use a 3kg pressure pure water gun to spray pure water at 60°C (spray temperature) (Conductivity at this temperature is about 15μs / cm) Spray all parts of the battery for 5 minutes, and then use hot air (pressure 3kg, temperature about 60°C) to dry the moisture on the surface of the battery for 3 minutes, and the cleaned battery is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com