A kind of environment-friendly fluorescent ink and preparation method thereof

A fluorescent ink, an environmentally friendly technology, applied in ink, household utensils, applications, etc., can solve the problems of affecting the health of printing workers, difficulty in long-term storage, pollution of the environment, etc., achieving bright fluorescent color, no color shift, and simple material composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Aqueous fluorescent liquid

[0024] The aqueous fluorescent liquid was prepared according to the following mass percentages: fluorescent pigment 4%, water 46%, ethanol 50%.

[0025] Water and ethanol were firstly added to the reaction vessel, and then fluorescent pigments were added under the condition of 550 r / min, and the mixture was dispersed for 50 minutes for later use.

Embodiment 2

[0027] The environment-friendly fluorescent ink was prepared according to the following mass percentages: 10% of the aqueous fluorescent liquid in Example 1; 45% of the first acrylic emulsion; 0.5% of emulsified Brazilian wax; 0.2% of tego8300; 1% of ethylene glycol methyl ether; 21% of ethanol ; Water 22.3%.

[0028] Add the remaining water and ethanol to the reaction kettle, slowly add acrylic emulsion, emulsified Brazilian wax, tego830 and ethylene glycol methyl ether while stirring under the condition of 300r / min, adjust the rotation speed to 600r / min after adding, Disperse for 30min and filter with 200 mesh filter cloth.

[0029] The fluorescent ink prepared in this example has no abnormal toxicity, and can be used for printing on white cardboard and coated paper. The drying speed is fast, and the printing speed is 80m / min~120m / min.

Embodiment 3

[0031] Prepare environment-friendly fluorescent ink according to the following mass percentages: 14% of the aqueous fluorescent liquid in Example 1; 50% of the first acrylic emulsion; 1.6% of Brazilian wax; 0.1% of tego8300; 1% of ethylene glycol methyl ether; 17.3% of ethanol; Water 16%.

[0032] Add the remaining water and ethanol to the reaction kettle, slowly add acrylic emulsion, Brazilian wax, tego830 and ethylene glycol methyl ether while stirring under the condition of 300r / min. 30min, use 200 mesh filter cloth to filter.

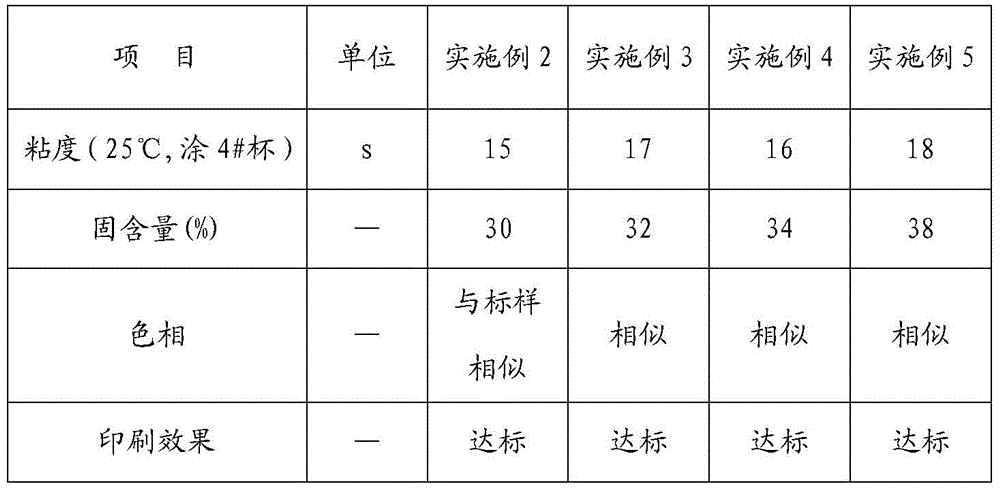

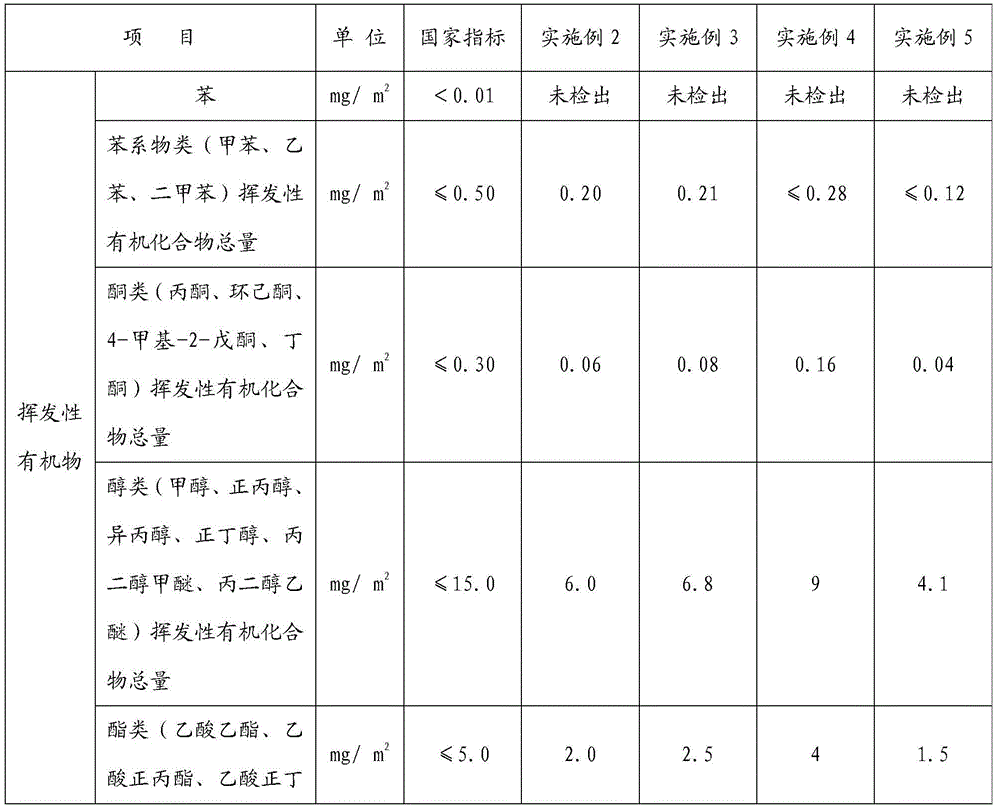

[0033] The fluorescent ink prepared in this example has no abnormal toxicity, and can be used for white cardboard, coated paper, and corrugated paper printing. It has fast drying speed, excellent printing effect and full color. The printing speed is 80m / min~120m / min. Table 1 to Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com