Heat sealing equipment and method for solar cell module

A technology of solar modules and sealing equipment, applied in the direction of electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problem of double-sided tape sealing and adhesion, unsatisfactory solar modules, shortening production and turnover Time and other issues, to achieve the effect of low cost, fast speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: as Figure 4 As shown, a single-layer heating and sealing device for solar modules includes a layer of heating units, the heating unit includes a conveying positioning mechanism 4 extending laterally on the lower layer, an annular heating mechanism 6 located on the upper layer, and a heating element located on the conveying positioning mechanism 4 and heating The jacking mechanism 5 in the middle part of mechanism 6. The conveying positioning mechanism 4, the heating mechanism 6 and the jacking mechanism 5 are all arranged on the upper end of the rectangular parallelepiped frame frame 3. The top of the frame 3 is provided with a guardrail 31 with a central opening, and a corner of the top is provided with a man-machine interface 1. The lower end is provided with electric control cabinet 2.

[0037] Such as Figure 5As shown, the conveying positioning mechanism 4 includes a roller conveyor whose conveying direction is transverse, and two front baffles 41 ...

Embodiment 2

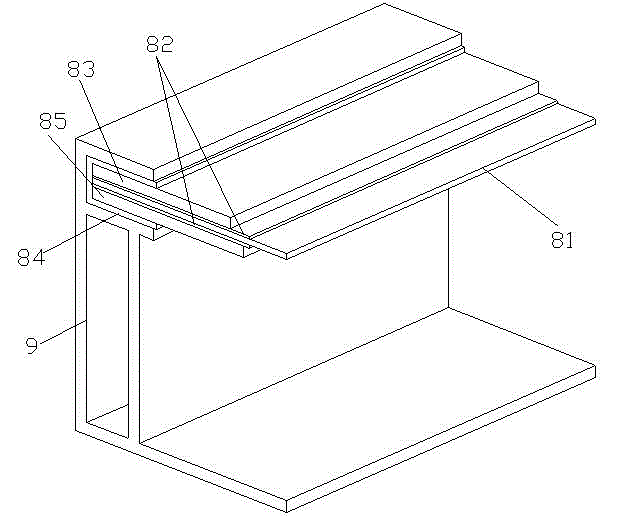

[0049] Embodiment 2: as Figure 8 As shown, a double-layer heating and sealing equipment for solar modules includes a square main frame 16, an inner frame 28 arranged inside the main frame 16 through a lifting mechanism, and upper and lower layers of heating elements arranged in the inner frame 28. Units 22, 24. The structure of each layer of heating unit is the same as that of the single layer of heating unit in Example 1. The lifting mechanism includes two driving screw rods 18 extending longitudinally between the upper heating unit 22 and the lower heating unit 24 and a lifting driver 26 connected to the driving screw rods 18 and extending transversely.

[0050] When the heating and sealing time of a solar module is longer than the time for a conveyor line to transport a solar module, it is necessary to use a heating and sealing device with multiple heating units to heat the solar module. For example, the speed at which the conveyor line transports the solar modules is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com