Induction sealing method for solar component

A solar module, solar technology, applied in electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problem that the aging resistance of double-sided tape is not suitable for long-term outdoor work, and the sealing and adhesion of double-sided tape are not too strong. The problems of conformity and sealing of solar modules are not ideal, so as to achieve the effect of low cost, fast speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

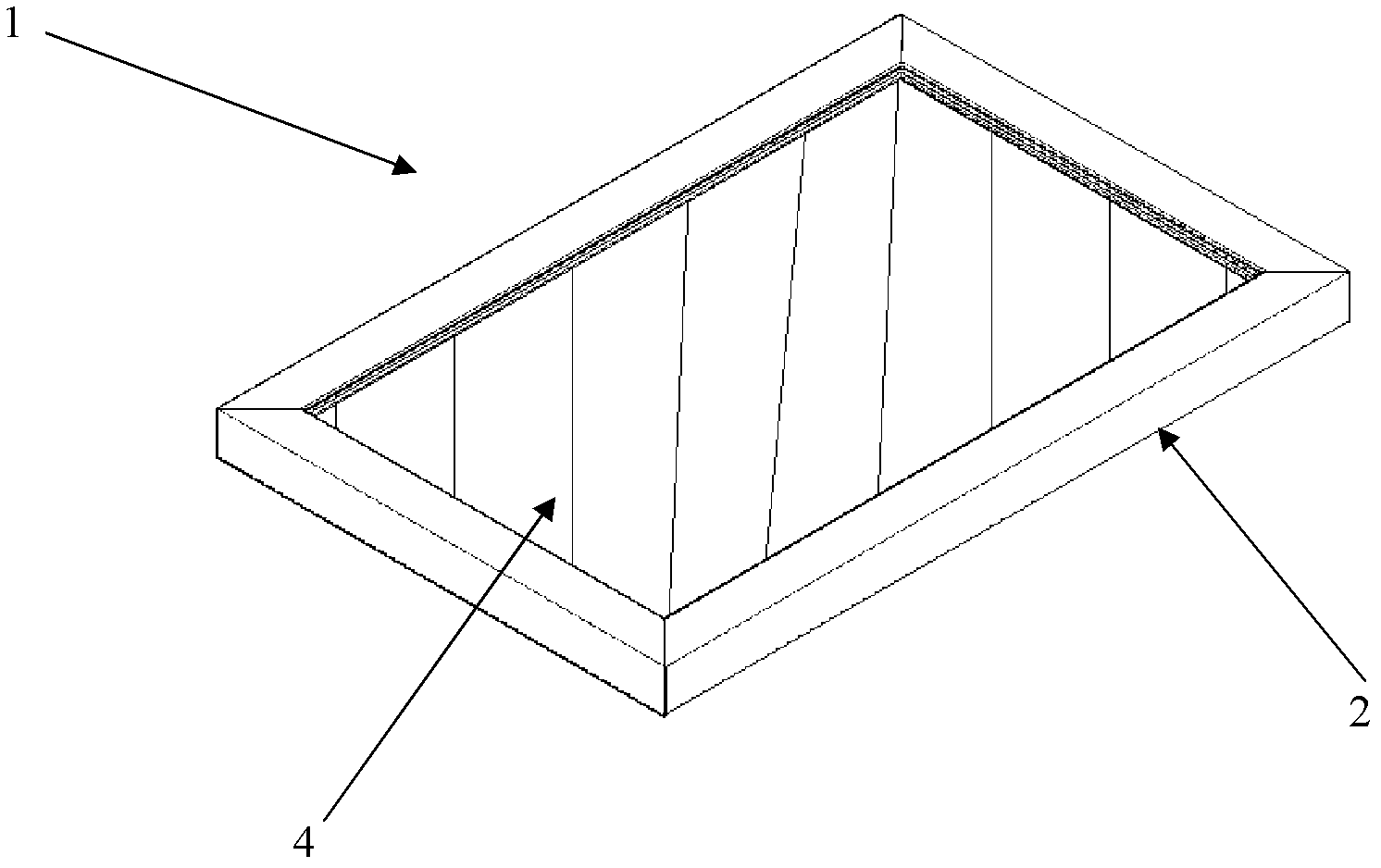

[0042] Such as figure 1 As shown, the solar module is composed of a solar laminated panel 4, a solar module sealing material 3, a solar aluminum frame 2 and a junction box. Among them, the solar laminated panel is composed of a front panel (mostly glass), connected battery sheets, packaging materials (such as EVA), and a back panel after lamination. The solar panel is sealed with a sealing material and installed in the solar frame, and a junction box is installed on the back of the solar panel to output the current formed by photoelectric conversion.

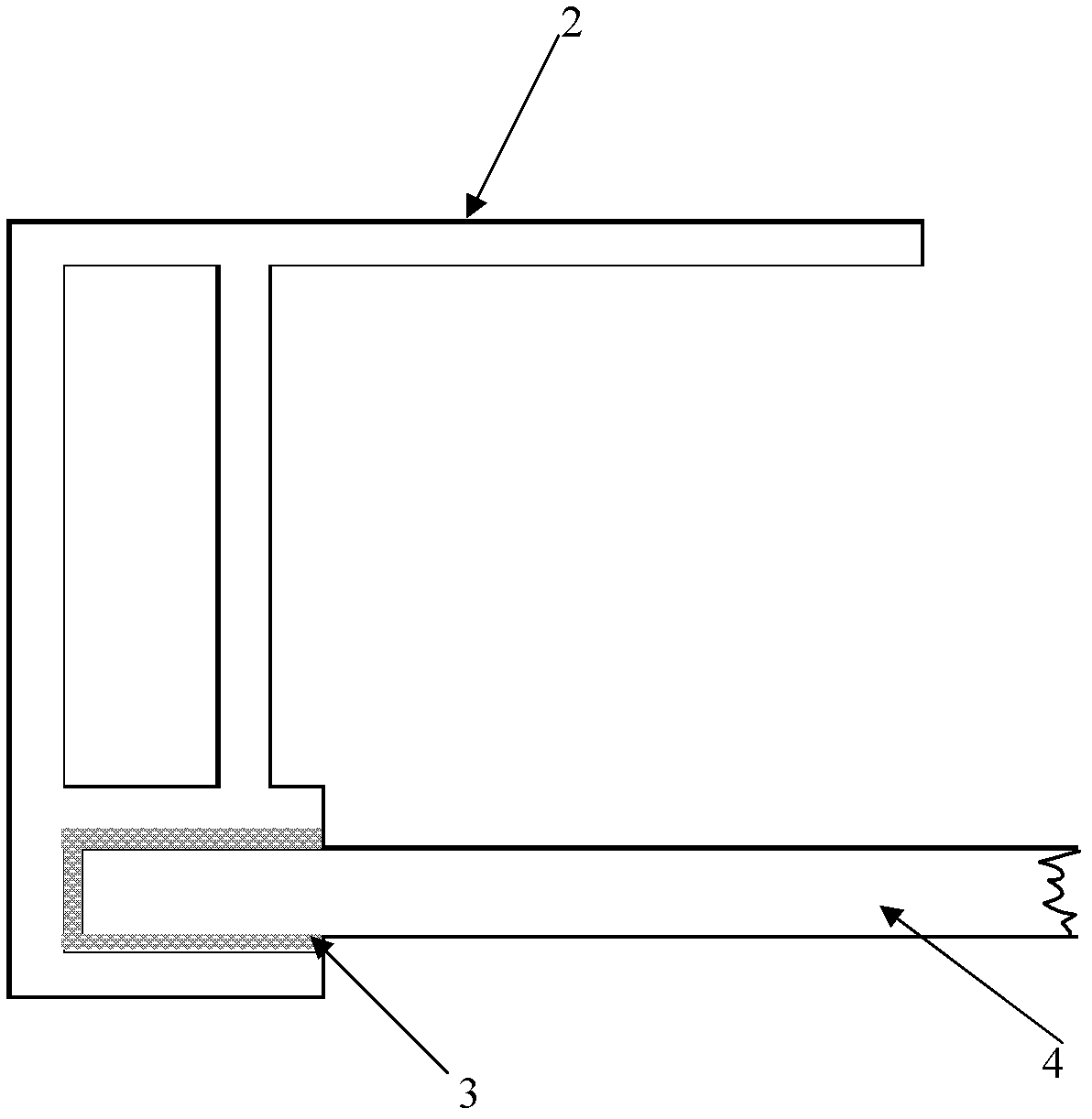

[0043] Such as figure 2 As shown, the heat-adhesive polymer sealing material 3 is placed on the periphery of the solar laminated panel 4, and then the solar aluminum frame 2 with grooves is clamped to the solar laminated panel 4, and fasteners (these fasteners can be screws or right-angle bolts, etc.) vertically connect the long frame and the short frame of the solar energy, clamp the long and short frames of the aluminum fr...

Embodiment 2

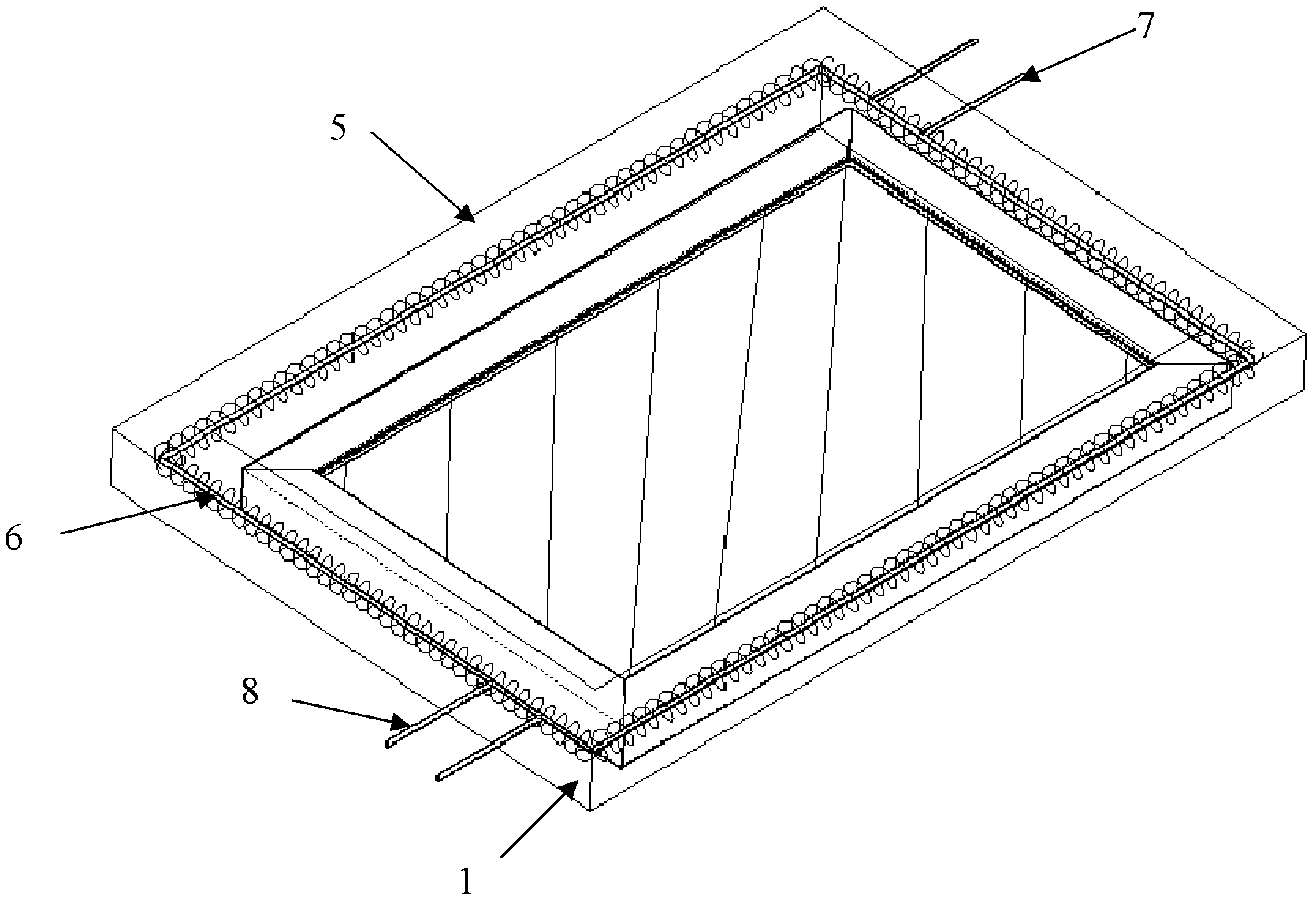

[0047] Place the induction head directly above the solar framing machine without using a transfer line, such as Figure 5 , the solar laminated panel is installed on the frame through the module frame machine, and there is a pre-installed sealing material inside the frame (the sealing material is silane grafted polybutene and ethylene-propylene copolymer with a mass ratio of 1:1), and screw Or the right-angle bolts vertically connect the long frame and the short frame of the solar energy, and clamp the long and short frames by external force, so that the sealing material evenly wraps the edge of the solar laminate in the groove, and is affected by a certain elastic force. At the same time, there is a double-wound induction head 5 above the solar framing machine. The induction head generates a magnetic field. Due to electromagnetic induction, the aluminum frame will generate an internal current under the action of the magnetic field of the sealing head, and then convert the elec...

Embodiment 3

[0049] Such as Figure 6 As shown, the induction coil of the induction-type sealing head adopts a single-wound strip-shaped structural frame, and the induction heating components of the induction-type sealing head are two sets of parallel first and second induction heating components, and the first and second induction heating components are arranged respectively. The second induction sealing head, the first and second induction sealing heads are respectively composed of two sets of induction heating components, the first and second induction sealing heads form an angle of 90°; the heating under the first induction sealing head The range is the first induction area, and the heating area under the second induction sealing head is the second induction area, and the two induction areas are perpendicular to each other on the same plane. The first inductive sealing head first heats and seals the two parallel sides of the aluminum frame of the solar module, then the solar module mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com