Forming device and forming method of powder metallurgy part

A technology of powder metallurgy and molding equipment, applied in the field of powder metallurgy, can solve the problems of difficult to realize large-scale automatic production, low molding efficiency, and time-lag molding products, etc. It is suitable for large-scale automatic production, improves molding stability, and is easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

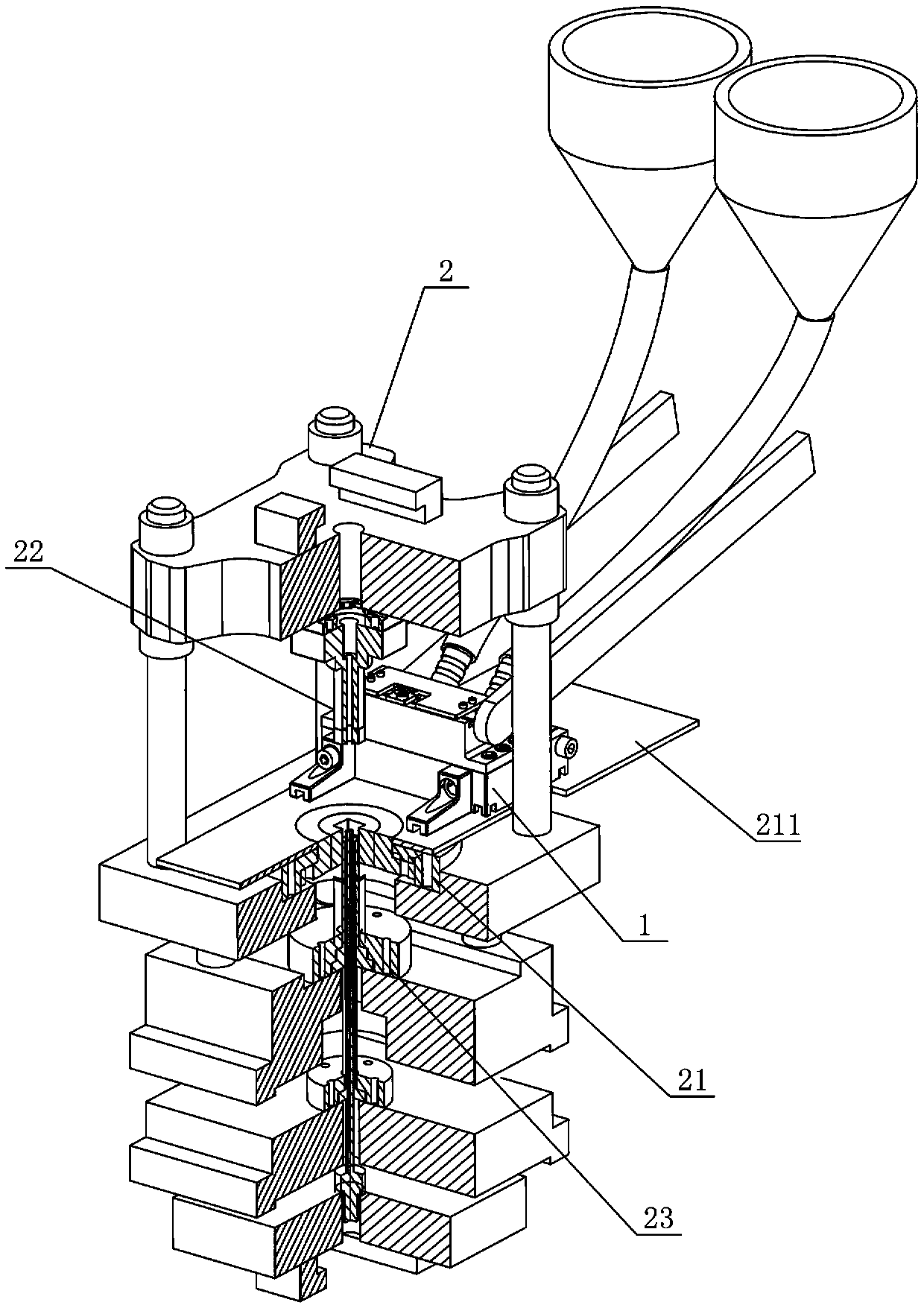

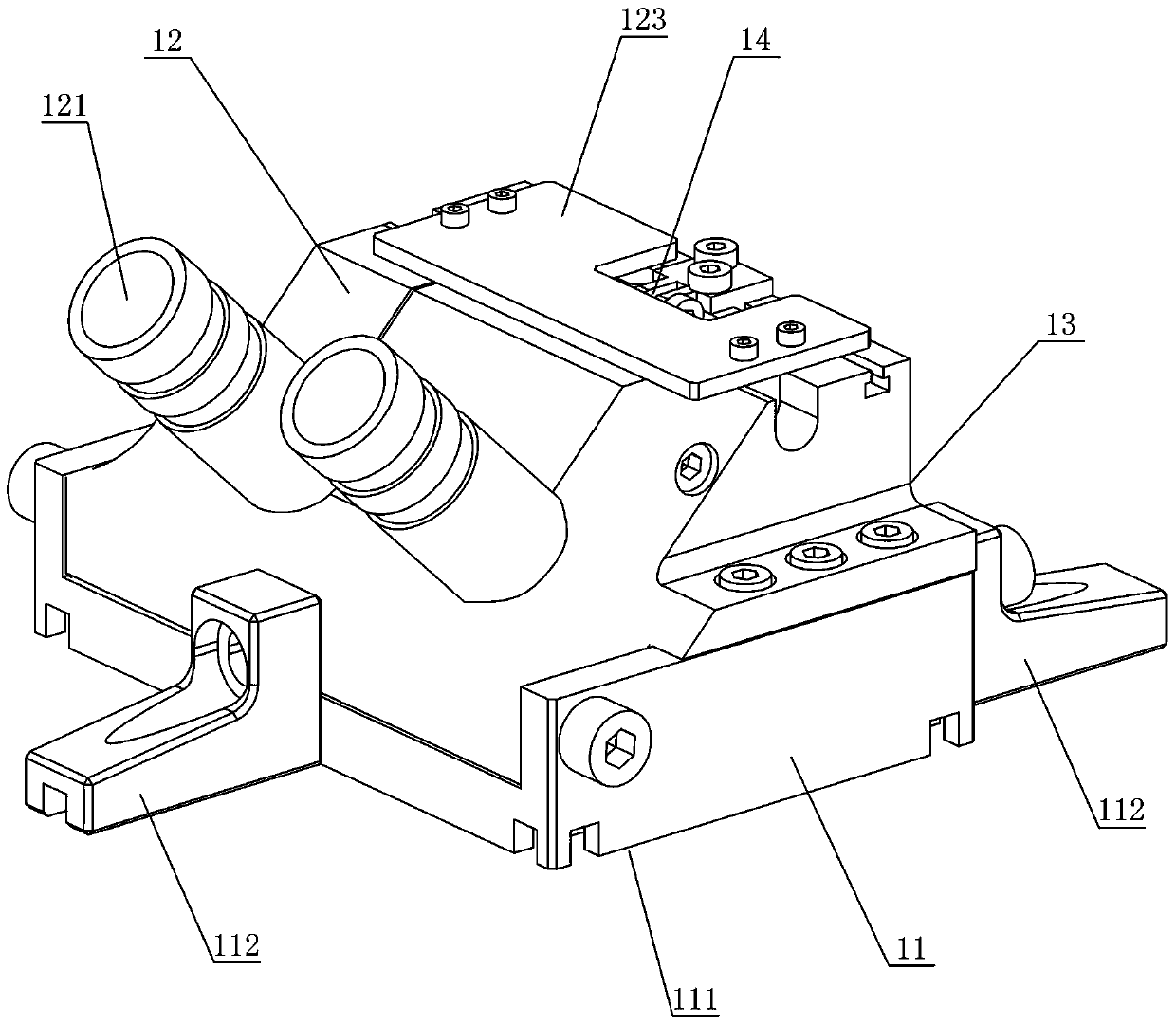

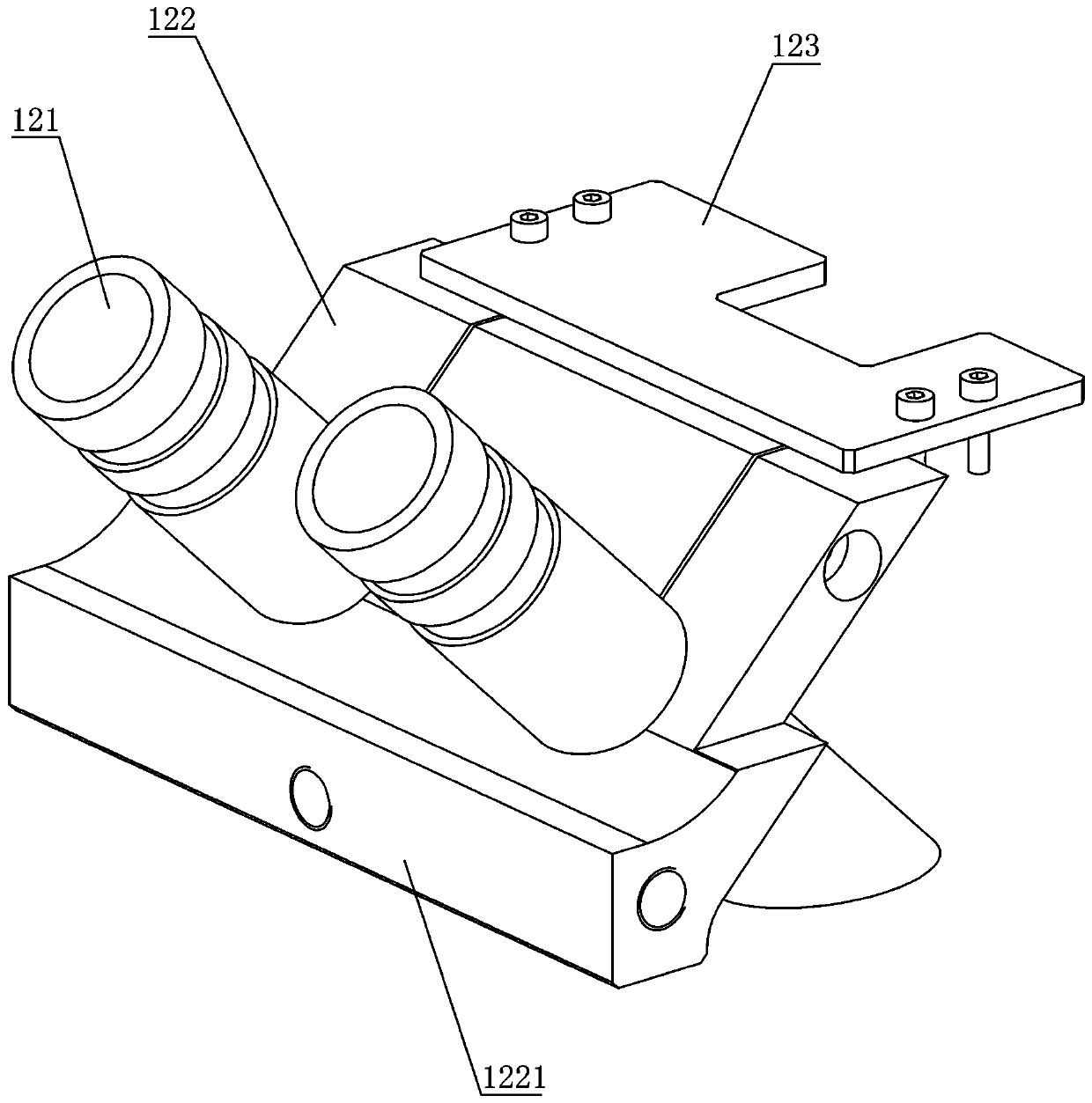

[0036] Figure 1 to Figure 5 It shows an embodiment of the molding device of powder metallurgy parts of the present invention, the molding device includes a feeding vessel 1 and a molding module 2, the feeding vessel 1 includes a base 11, a plurality of optional front sealing covers 12, a rear sealing Cover 13 and a plurality of optional partitions 14, each front cover 12 is provided with at least two feeding tubes 121, and the number of feeding tubes 121 on each front cover 12 is different, and the base 11 is provided with There is a through discharge port 111, the discharge port 111 is docked with the feed end of the forming module 2, the front cover 12 and the rear cover 13 are connected to each other and are set on the top of the base 11 together, and the feeding pipes of the front cover 12 121 stretches into the discharge port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com