Partial plate bending device

A bending device and local technology are applied in the field of local bending operation devices for plates, which can solve the problems of inconvenient post-production and adjustment, poor use flexibility, and increased production costs, and achieve compact structure, flexible use and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

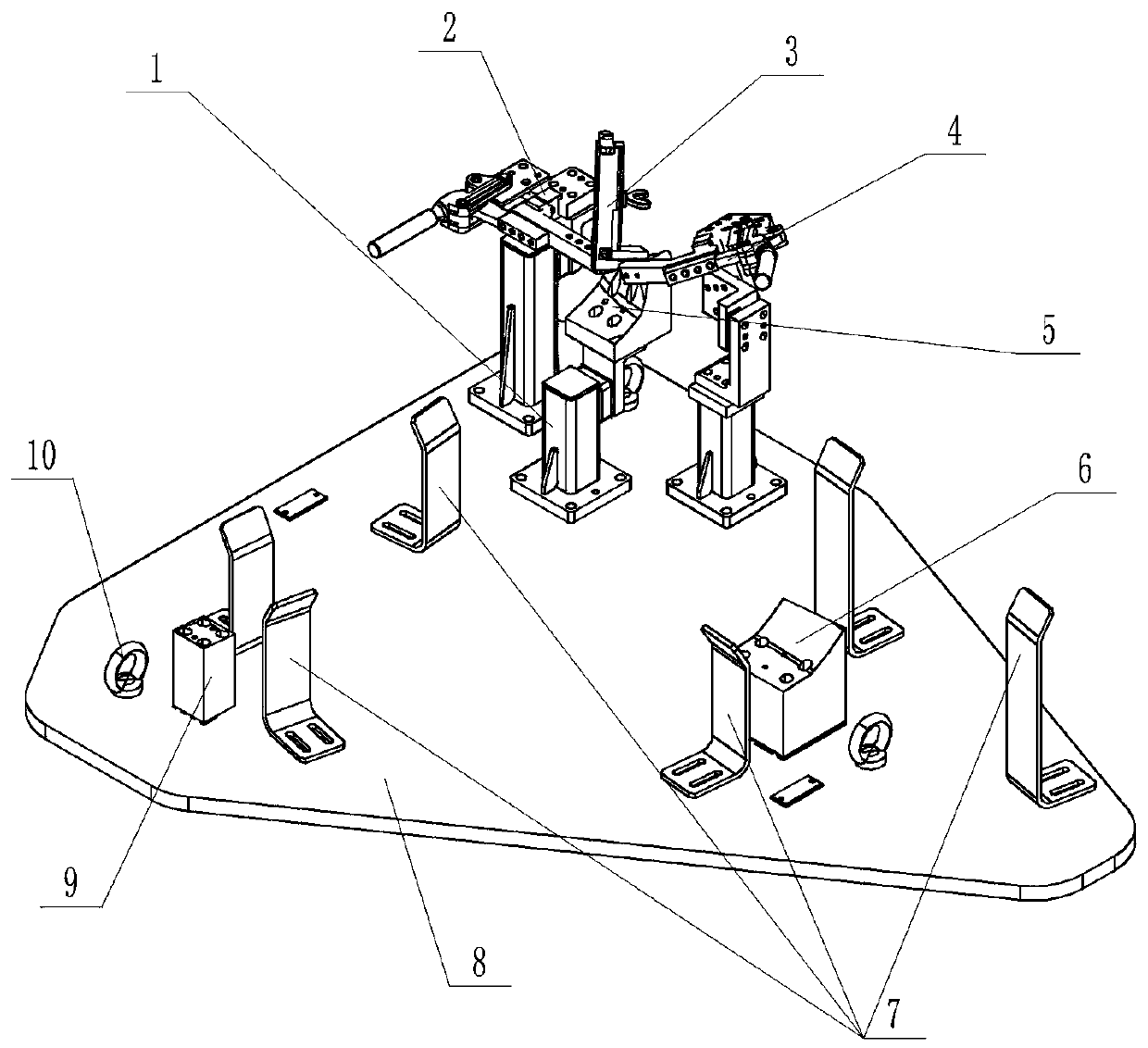

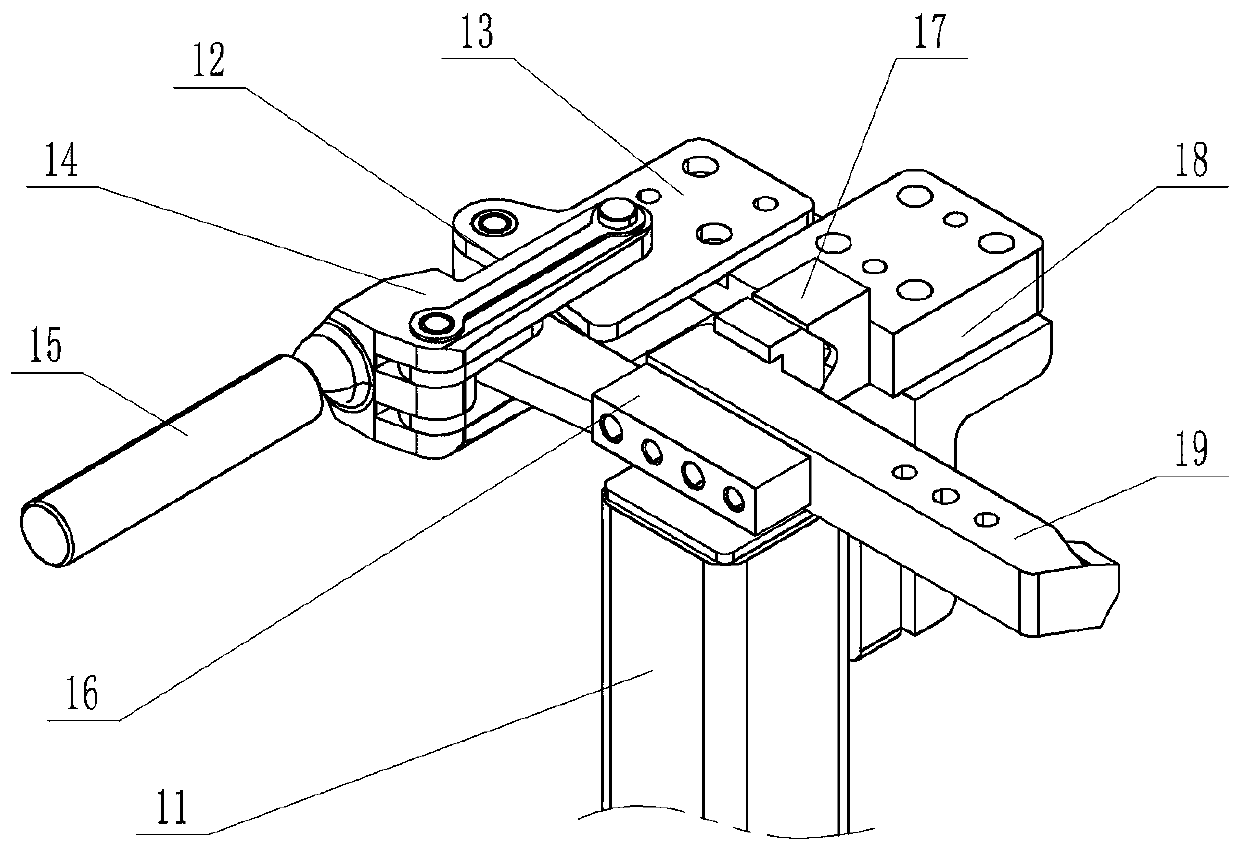

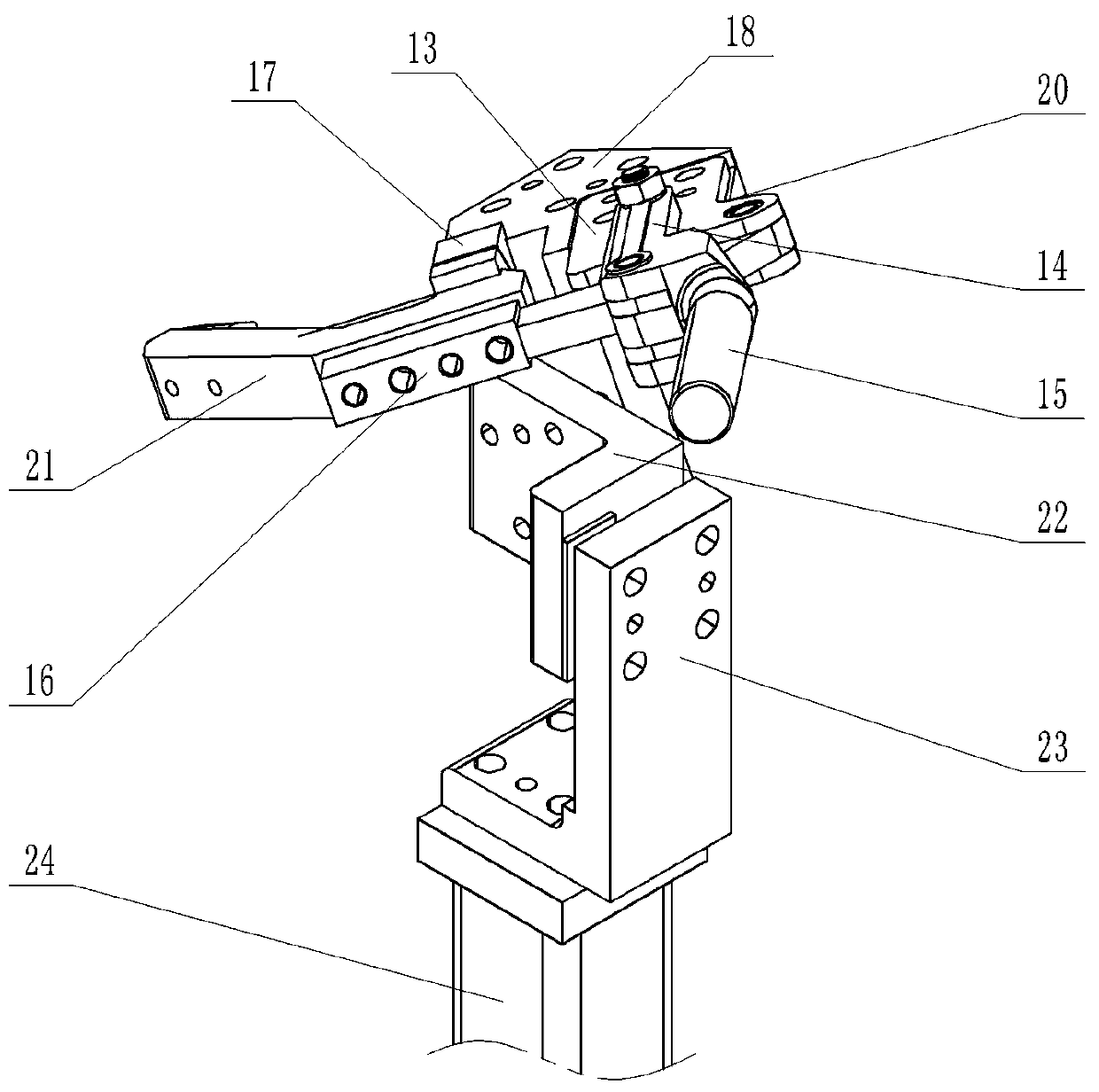

[0021] according to Figure 1-7 The specific structure of the present invention will be described in detail. The plate partial bending device includes a clamping and positioning mechanism 1 for positioning the plate to be bent, and a hand-held bending tool 3 for bending, wherein the clamping and positioning mechanism 1 includes a triangular positioning bottom plate 8, and the positioning The upper part of the bottom plate 8 and the positions in contact with the edge of the plate to be bent are respectively provided with several vertically arranged supporting and fixed baffles 7; the upper part of each supporting and fixed baffle 7 is respectively provided with a Bend end where the outside edge of the part is bent. At the positions of the corners around the triangular positioning bottom plate 8, end support blocks I6 and end support blocks II9 for supporting the ends of the two sides of the plate to be bent are respectively provided, as well as the bending part for supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com