Machine head cutter swing arm and connection rod device

A technology of connecting rod device and cutter, applied in shearing device, shearing machine equipment, metal processing equipment and other directions, can solve the problems of high energy consumption, low control precision, high noise, etc., and achieve the effect of strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

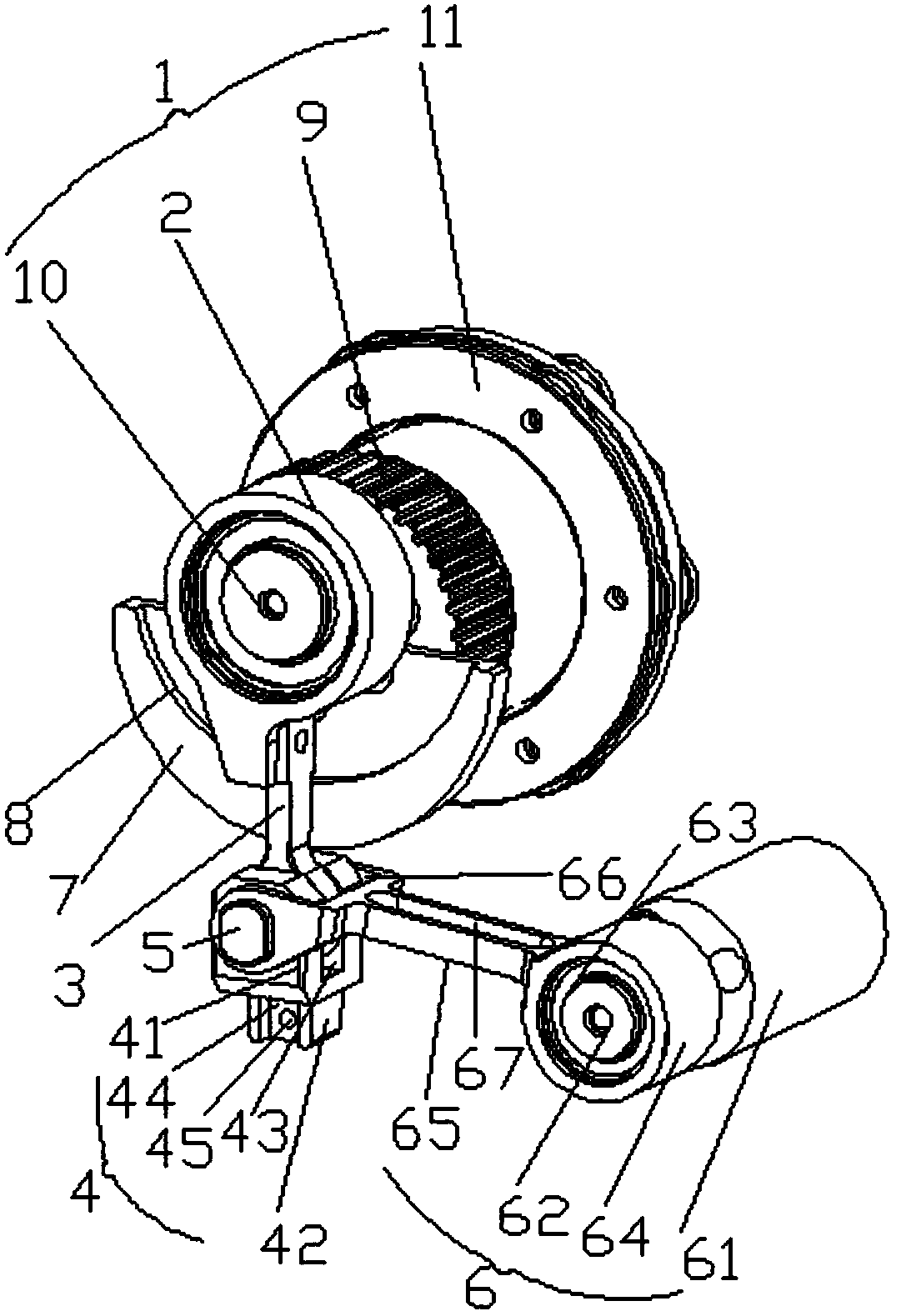

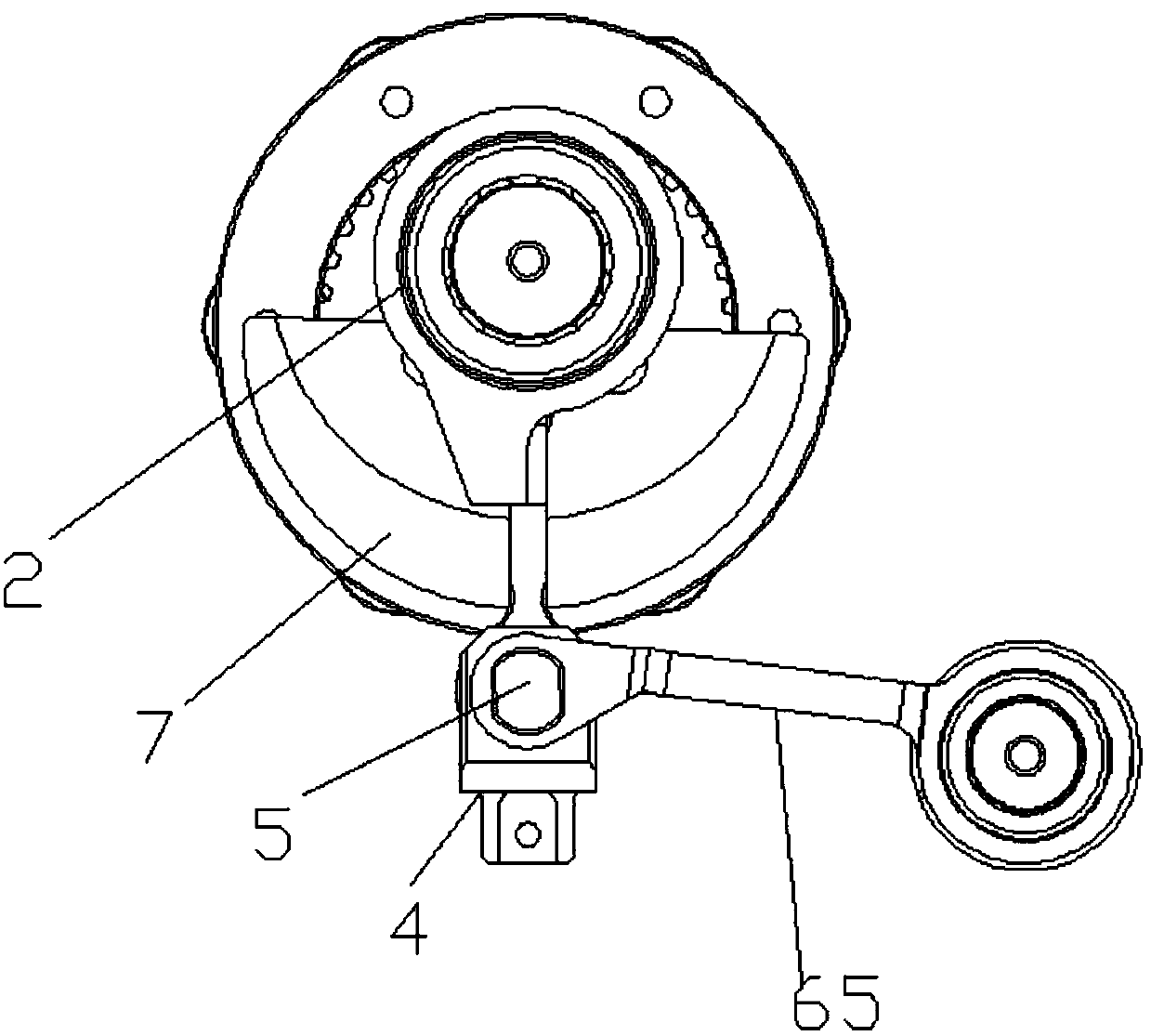

[0017] Such as figure 1 and figure 2 As shown, a head cutter swing arm linkage device includes a cam transmission mechanism 1, and a cam 2 of the cam transmission mechanism 1 is connected with a connecting rod 3 that is controlled by the cam transmission mechanism 1 to continuously move vertically up and down. The lower end of 3 is movably connected on a card arm 4, and card arm 4 is articulated by pin 5 and is used for controlling the vertical movement distance of connecting rod 3 and the swing arm mechanism 6 for offsetting connecting rod 3 swing force.

[0018] Preferably, the swing arm mechanism 6 includes a swing arm support 61, the end of the swing arm support 61 is provided with a tip 62 with a diameter smaller than the swing arm support 61 diameter, the tip 62 is sleeved w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com