Application method of tool applied to inner wall cleaning of tube fittings

An application method and cutting tool technology, which are applied in the field of argon arc welding machine auxiliary equipment, can solve the problems such as the decrease of the fluid flow rate in the pipe, the decrease of the strength of the weld, and the decrease of the stability of the steel pipe, so as to achieve flexible connection methods, improve cleaning efficiency, shorten The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

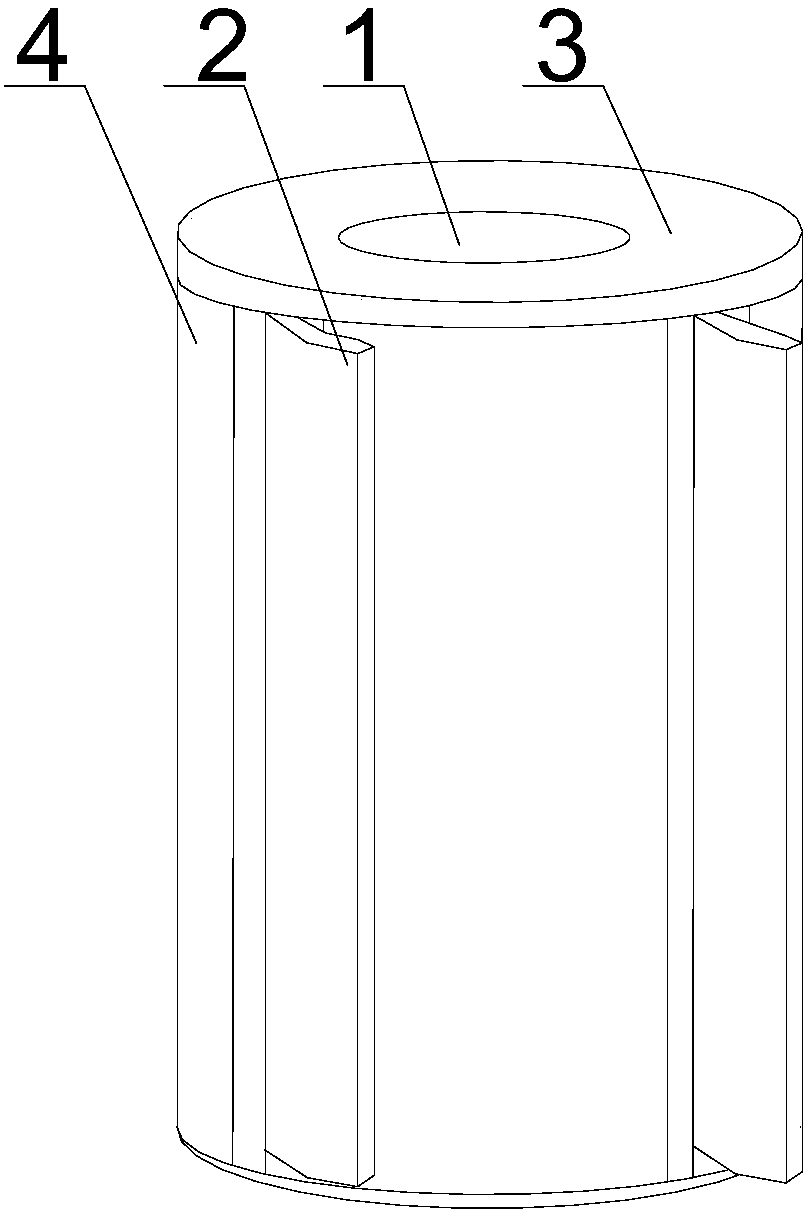

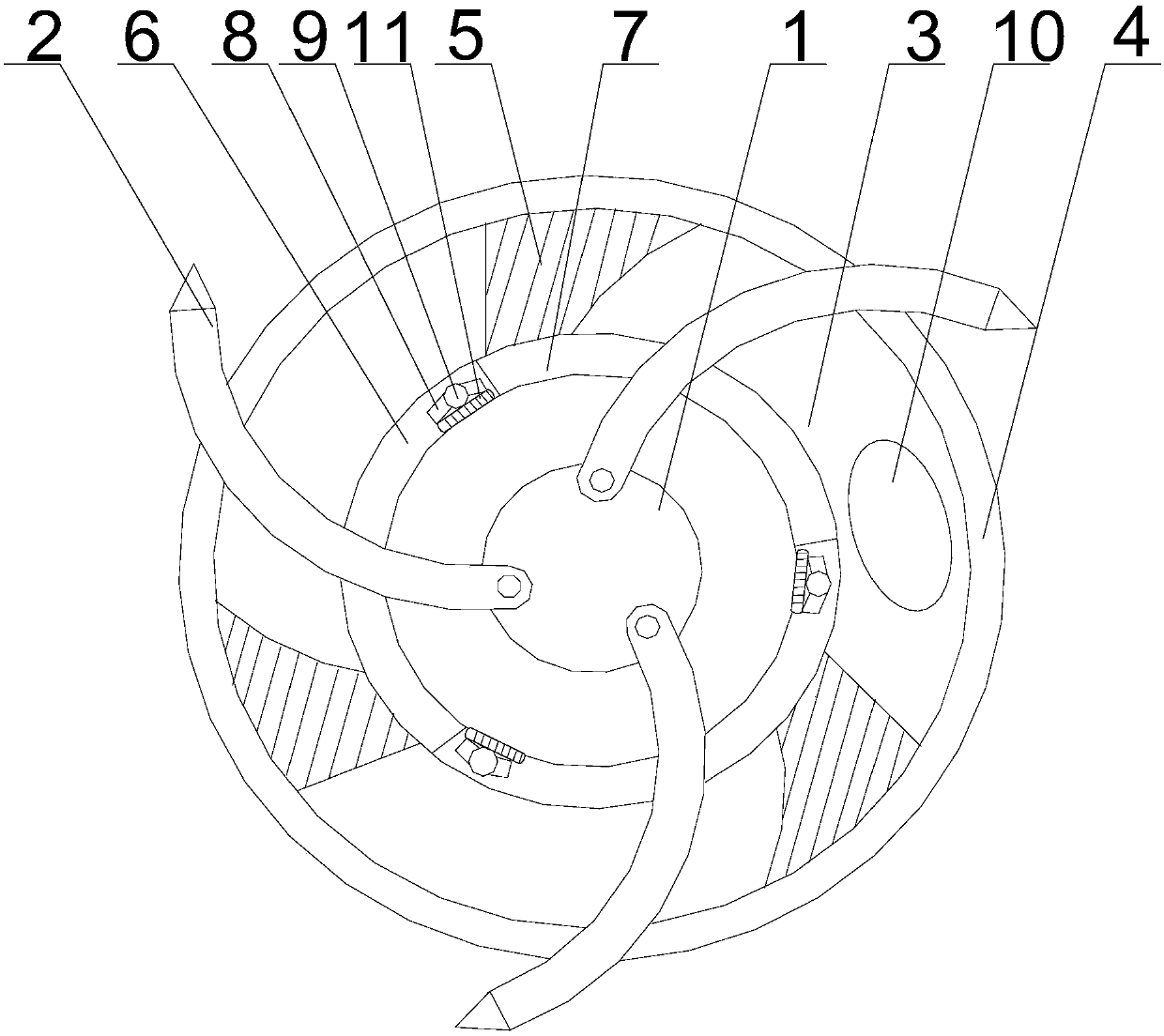

[0020] like figure 1 and figure 2 As shown, the outer burr cleaning mechanism of the welded steel pipe of the present invention includes the following steps, the central shaft 1 is driven to rotate by an external driving device, the arc-shaped blade 2 on the central shaft 1 rotates, and the solder residue and protrusions on the inner wall of the steel pipe are started to be removed. Clearing; three arc-shaped blades 2 are located on one-third of the outer wall of the central axis 1 and are hinged with the central axis 1, so that the arc-shaped blades 2 can change their removal radius through the angle adjustment mechanism of the blade 2 according to the size of the steel pipe diameter. Increase or reduce the clearing range of the arc blade 2 at any time, which increases the practicability of the present invention; the angle adjustment mechanism of the blade 2 of the present invention adopts a flexible connection mode and a simple structure, while ensuring that the arc blade 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com