Adjustable fiber cutting-off and weighing device

A weighing device and adjustable technology, which is applied in measuring devices, weighing equipment for materials with special properties/forms, fiber bundles into fiber strips/yarns, etc., can solve the problem of no fiber cutter, blunt knife edge, Fiber bundles are easy to tilt and other problems, to achieve the effect of reducing human interference, accurate measurement results, and convenient adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

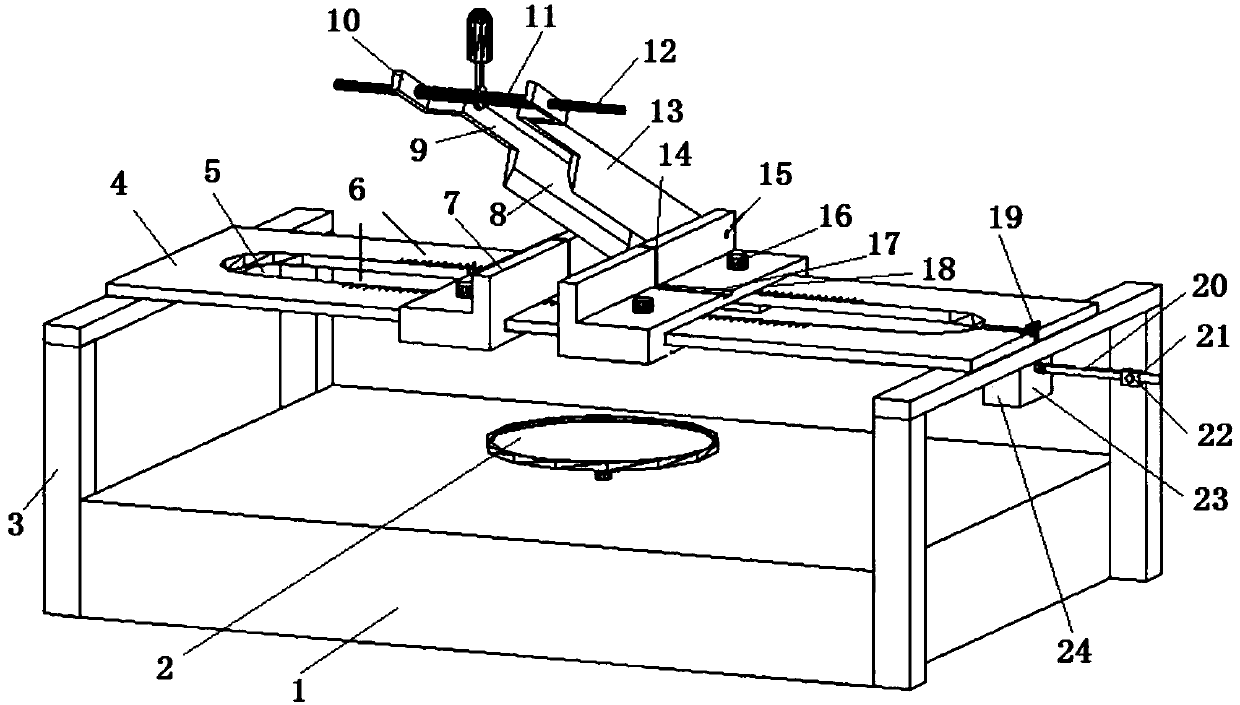

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

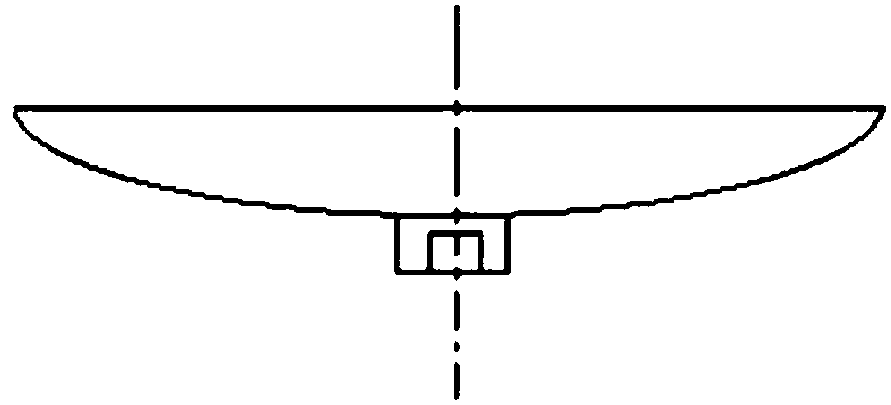

[0018] The present invention consists of six major parts, the first part is 3 parts of the splint bracket; the second part is the shearing part; the third part is the limit part; the fourth part is the cut adjustment part; the fifth part is the fiber or fiber bundle tension control part ; The sixth part, electronic balance 1 for weighing. The shearing part, the notch adjustment part, the limit device and the fiber bundle tension control part are all assembled on the splint bracket 3, and the notch adjustment part is adjusted by sliding the L-shaped splint 7 to set different shearing distances. The whole fiber cutting device is arranged on the electronic balance 1 and kept horizontal with the electronic balance 1 . The center of the weighing tray 2 of the electronic balance 1 is concentric with the center of the cutter with a certain distance.

[0019] During specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com