Lateral connected roof bottom board and a roof board system

A technology of base plates and connectors, which is applied to roofs, roofs, and roof coverings using flat/curved panels. It can solve the problems of easy water seepage and poor wind resistance when fixing self-tapping screws to improve waterproof performance. Enhanced strength and improved wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

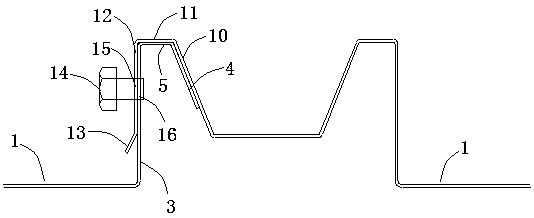

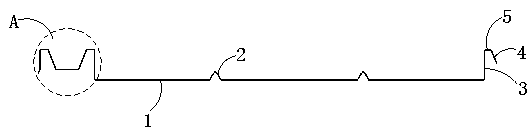

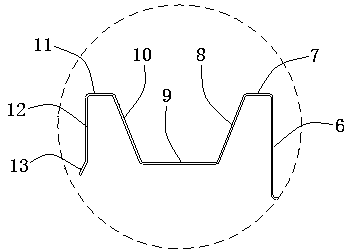

[0028] like figure 1 As shown, this embodiment provides a laterally connected roof bottom plate, including several bottom plates connected in sequence, the bottom plate includes a bottom plate 1 and a supporting rib 1 and a supporting rib 2 respectively disposed at opposite ends of the bottom plate 1 . , the first support rib includes a plate rib and a connecting piece extending outward from the end of the bottom plate 1, the connecting piece and the second supporting rib have a matching downward bending structure, and the two adjacent bottom plates are connected When fixing, the bending structure of the second supporting rib of one of the bottom plates is sleeved into the bending structure of the connecting piece of the other adjacent bottom plate, and then the connecting piece of the two bottom plates and the second supporting rib are connected by the fastener 14. Bend the sides of the structure to fix the two bottom plates. The connection between the two adjacent bottom pl...

Embodiment 2

[0034] On the basis of the above examples, if Figure 4 As shown, this embodiment provides a roof panel system, including the above-mentioned roof base plate, and the top plate 17 arranged above the roof base plate, the adjacent roof plates 17 are connected by locking devices, and the connection between two adjacent roof base plates It is connected with the locking device through the support assembly.

[0035] Wherein, the locking device includes a support keel 19 and a buckle cover 20, the end of the top plate 17 is clamped between the support keel 19 and the buckle cover 20, and the lower end of the support keel 19 is connected with the support assembly; the buckle There is a flange 21 extending outward and obliquely downward at the edge of the cover 20. The support keel 19 is located in the vertical projection of the buckle cover 20, and the support keel 19 and the buckle cover 20 are fixed by bolts to compress the top plate 17. A cap 22 is provided above the buckle cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com