Installing structure of circuit board in refrigerating compressor

A technology for refrigeration compressors and installation structures, applied to compressors, refrigerators, refrigeration components, etc., can solve the problems of poor cooling effect, high temperature of circuit board boxes, and far wiring, etc., to achieve lower temperature and better heat absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

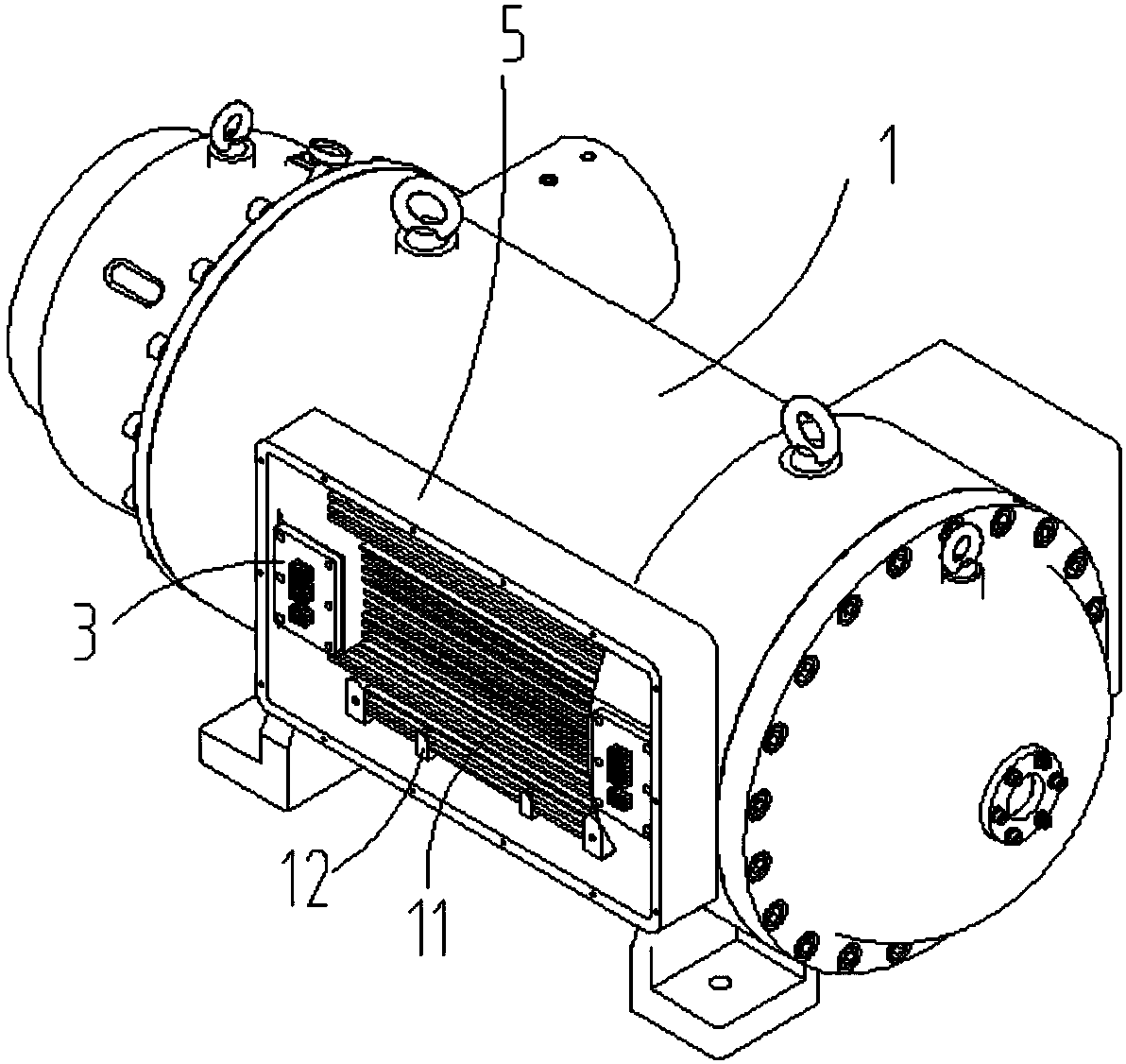

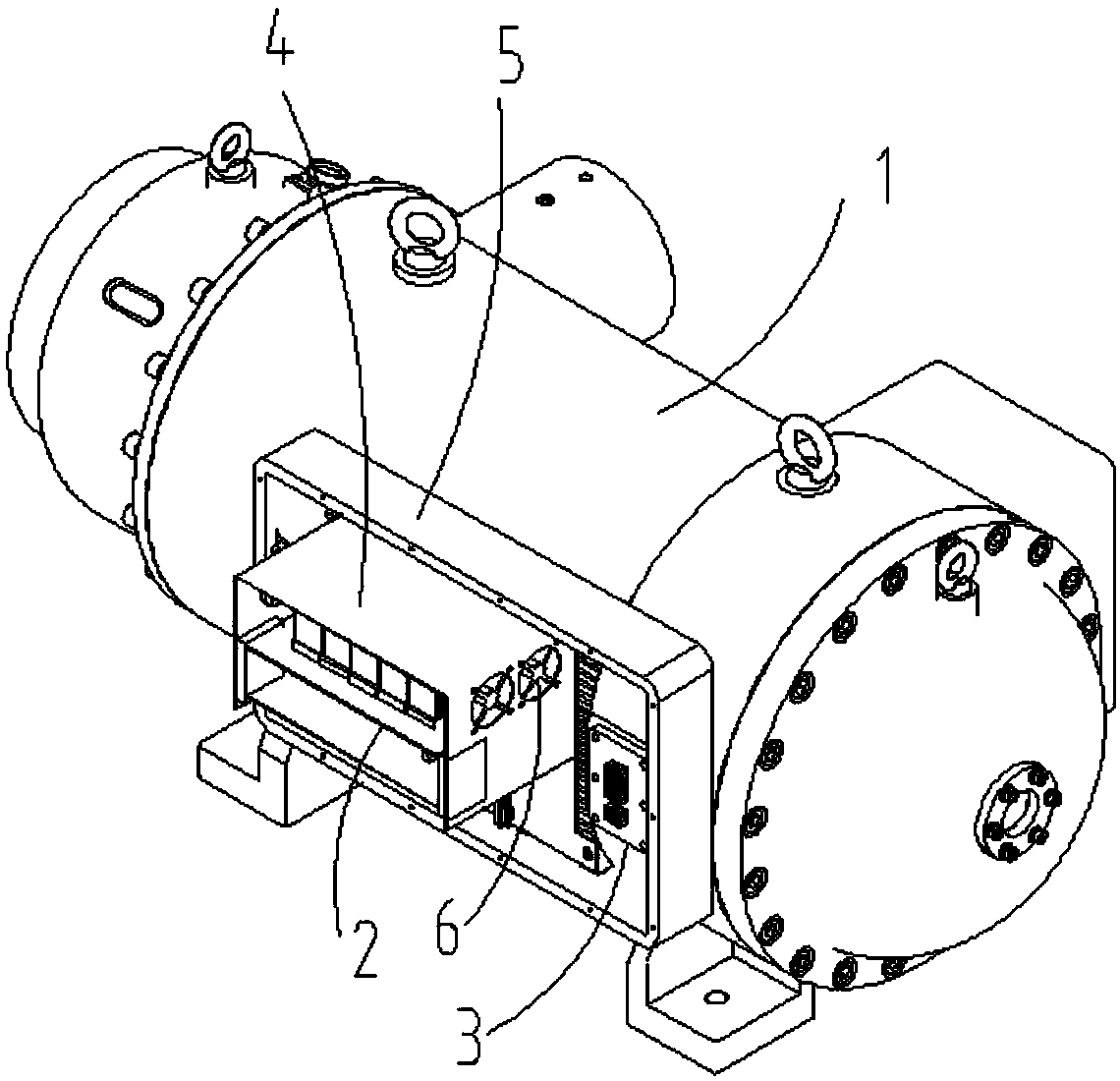

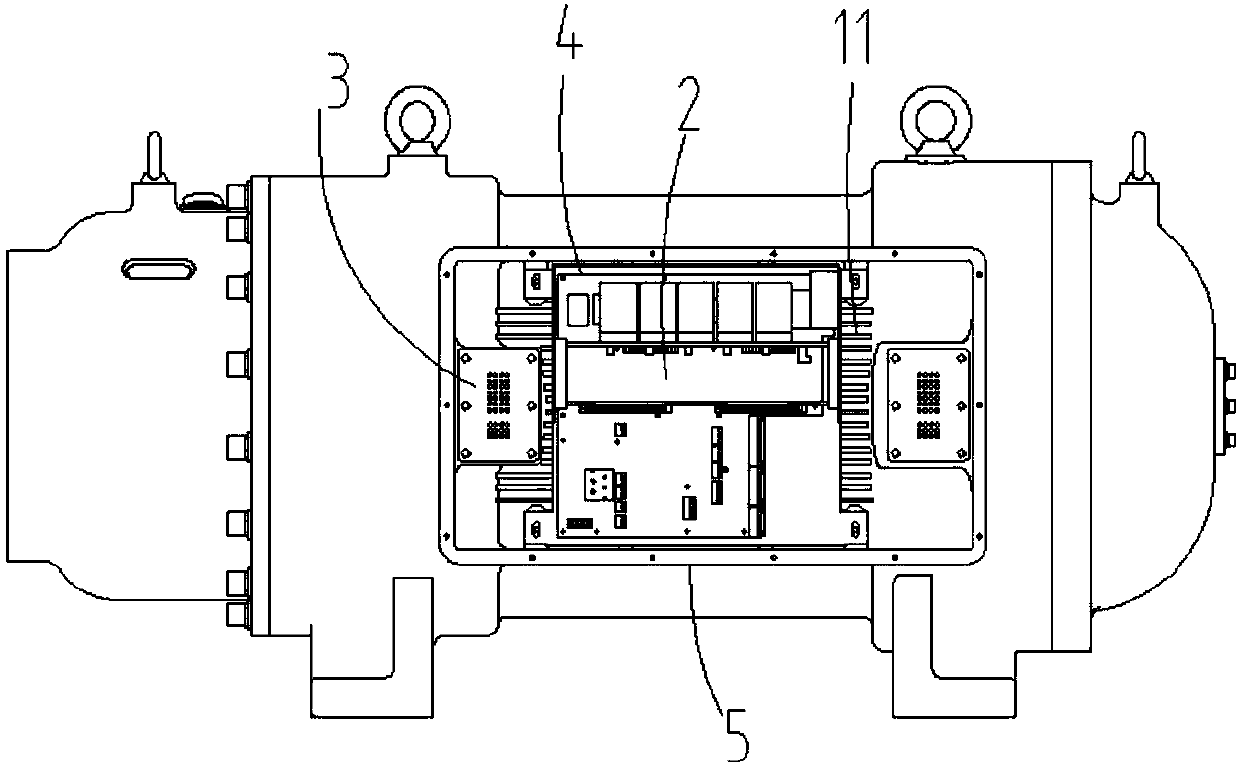

[0013] Such as Figure 1 to Figure 4 , the invention discloses a circuit board installation structure in a refrigeration compressor, including a refrigeration compressor casing 1, a circuit board 2, an electrical connector 3, a circuit board support 4, a frame body 5 and a cooling fan 6, two electrical connectors 3 is fixedly connected to the outer wall of the refrigeration compressor housing 1, and the two electrical connectors 3 are connected to the circuit board 2. The frame body 5 is fixedly connected to the outer wall of the refrigeration compressor casing 1, and the cooling fins 11 are arranged on the outer wall of the refrigeration compressor casing 1. The heat dissipation fins 11 are placed in the frame body 5, and the two electrical connectors 3 are symmetrical. Located on both sides of the cooling fins 11 , the circuit board support 4 is fixed on the cooling...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap