A mems gas differential pressure sensor

A differential pressure sensor and gas technology, applied in the field of sensors, can solve the problems of low sensitivity and achieve the effects of high sensitivity, small zero drift and high dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

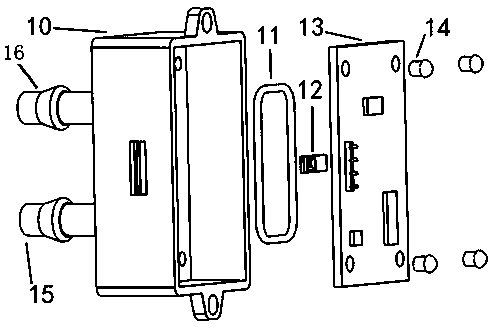

[0018] MEMS gas differential pressure sensor, its structure includes a housing 10, a sealing rubber ring 11, a chip 12, and a circuit board 13; wherein, there is a groove in the middle of the housing 10, the chip 12 is in the groove, and the circuit board 13 is covered above the groove , There is a sealing rubber ring 11 between the circuit board 13 and the housing 10 .

[0019] The circuit board 13 and the housing 10 are fixedly connected by fixing screws 14 , or the circuit board 13 and the housing 10 are directly bonded with a sealant.

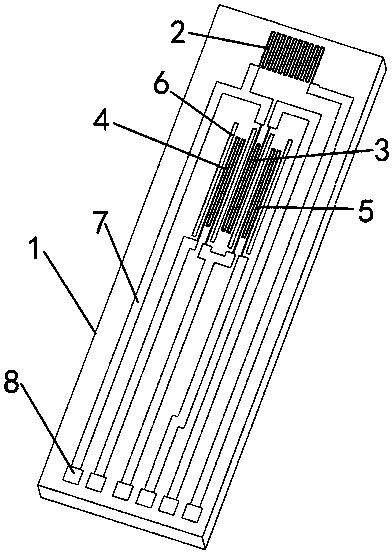

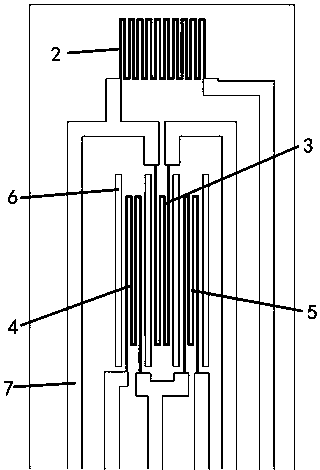

[0020] The chip 12 includes a substrate 1, an environmental resistance 2, a heating resistance 3, a first temperature detection resistance 4, a second temperature detection resistance 5, four heat insulation grooves 6, several wires 7, lead pads 8, and a back chamber 9 ; Wherein, the environment resistance 2, the heating resistance 3, the first temperature detection resistance 4, and the second temperature detection resistance 5 are on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com