Optical fiber hydrogen sensor based on au@pd nanoparticles and its preparation method and application

A nanoparticle and sensor technology, which is applied in the field of optical fiber hydrogen sensor based on Au@Pd nanoparticles and its preparation, can solve the problems that the comprehensive performance of the sensor cannot be improved, the diffusion distance of hydrogen atoms can be reduced, and the signal modulation ability can be weakened, etc., to achieve Good application prospects, small zero drift, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

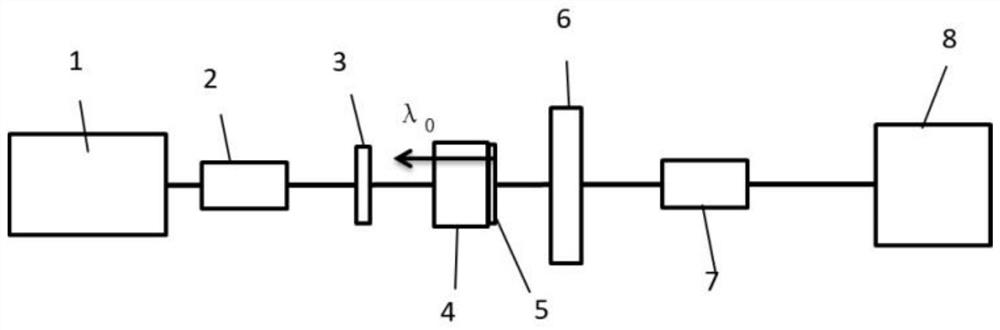

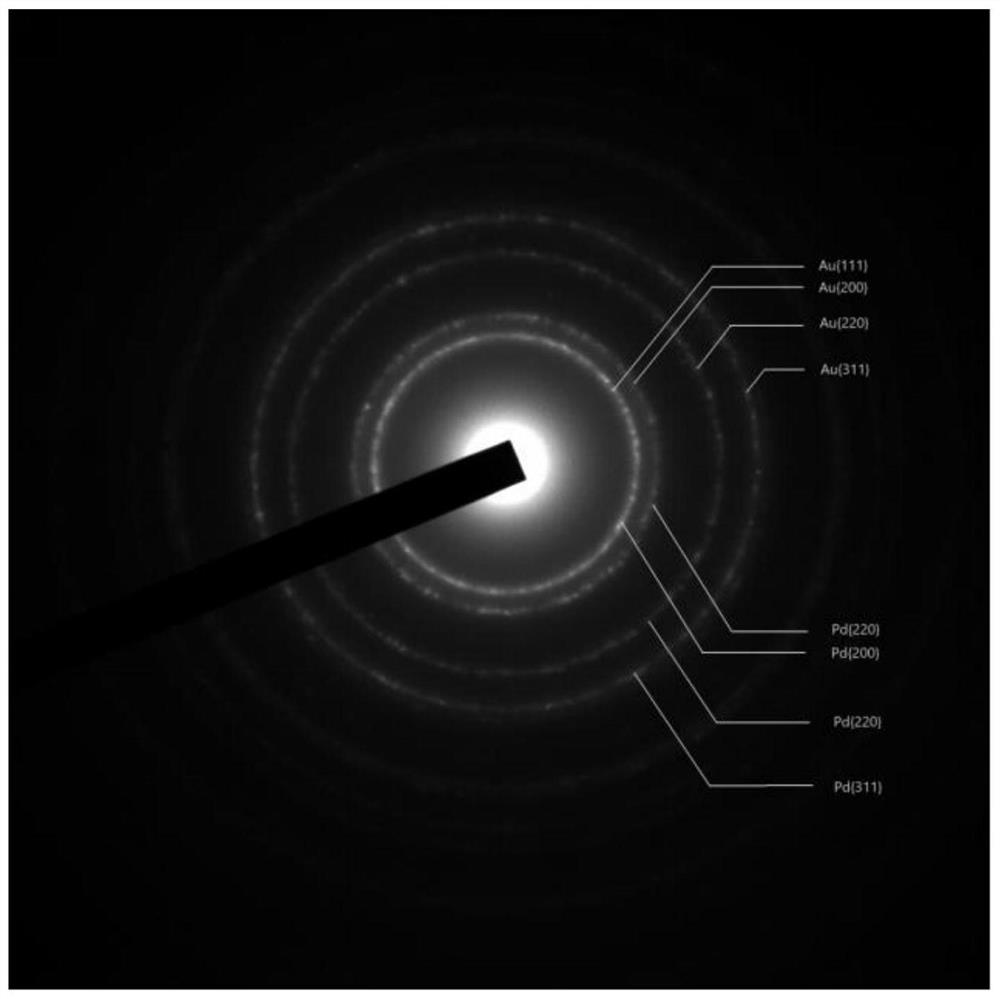

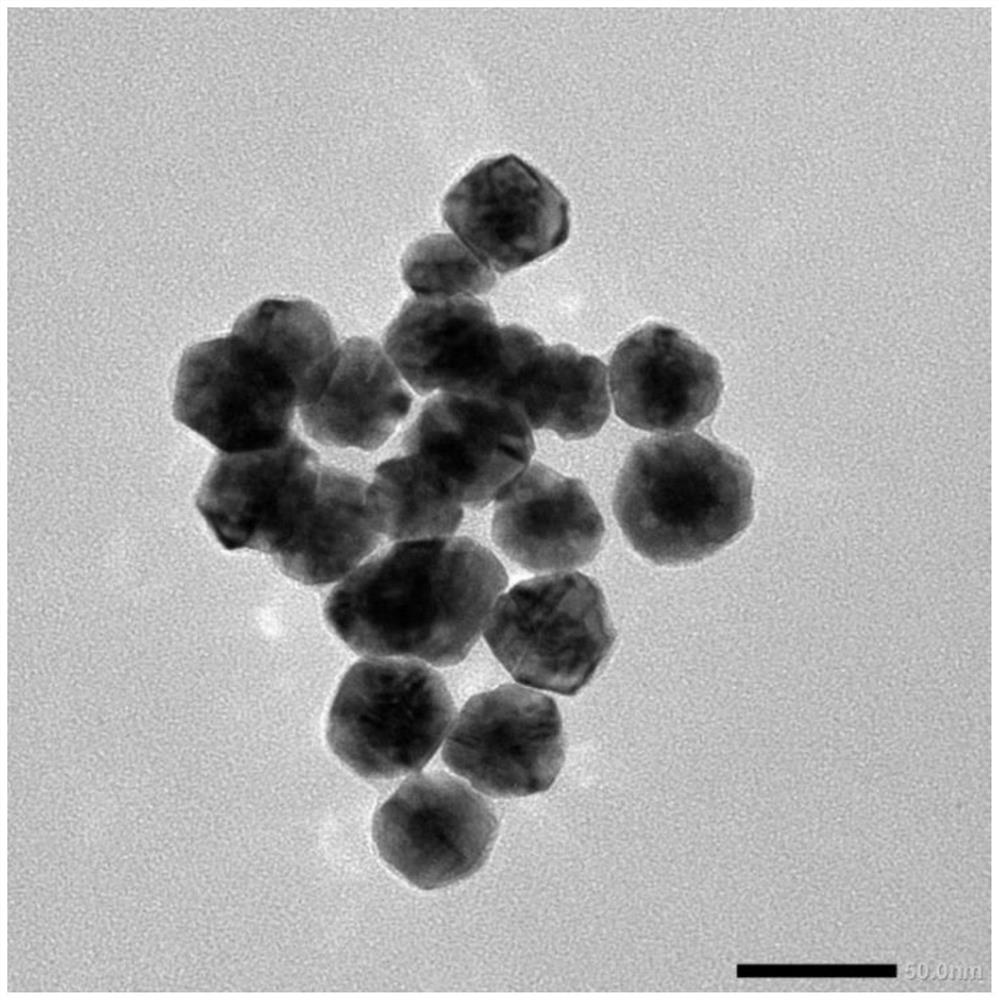

[0039] Provided is an optical fiber hydrogen sensor based on Au@Pd nanoparticles, comprising a flexible substrate, a nano-grating structure on the surface of the flexible substrate, and an Au@Pd nano-particle monolayer film covering the surface of the nano-grating structure. Among them, the gold core diameter in Au@Pd nanoparticles is 12nm; the average thickness of the palladium shell is 3nm; the flexible substrate is a single-layer structure with a thickness of 0.5mm; the nano-grating structure is a two-dimensional structure with a period of 416.6nm and a groove depth of 110nm, the duty cycle is 50%, and the groove width is 208nm.

[0040] The hydrogen-sensitive material adopts a gold-palladium core-shell structure nanoparticle monolayer film, which is no longer a continuous film. After repeated use, the continuous film is prone to delamination and rupture, causing the film to fail. Large zero drift and poor stability. However, the present invention greatly increases the con...

Embodiment 2

[0044] Provide an optical fiber hydrogen sensor with the same embodiment 1, the difference is: the size of the gold core in the Au@Pd nanoparticle film is 12nm, and the average thickness of the palladium shell is 6nm.

[0045] Figure 5 It is the response curve of the optical fiber hydrogen sensor in this embodiment, as shown in the figure: 0.1% hydrogen gas is introduced, the average response speed is 10s, the average response amplitude is 18mV, the zero point drift is 0.2mV, and the stability is excellent.

Embodiment 3

[0047] Provide an optical fiber hydrogen sensor with the same embodiment 1, the difference is: the size of the gold core in the Au@Pd nanoparticle film is 40nm, and the average thickness of the palladium shell is 3nm.

[0048] Image 6 It is the response curve of the optical fiber hydrogen sensor in this embodiment. The figure shows that 0.1% hydrogen gas is injected, the average response speed is 8s, the average response amplitude is 20mV, the zero point drift is 1mV, and the stability is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com