Optimized scheduling method applied to distributed production and manufacture process of notebook parts

A technology for optimizing scheduling and manufacturing processes, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as poor heuristic optimization methods, DPFSSP_LBNP difficulties, etc., to enhance local search capabilities and overcome parts The effect of the distribution information being disrupted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

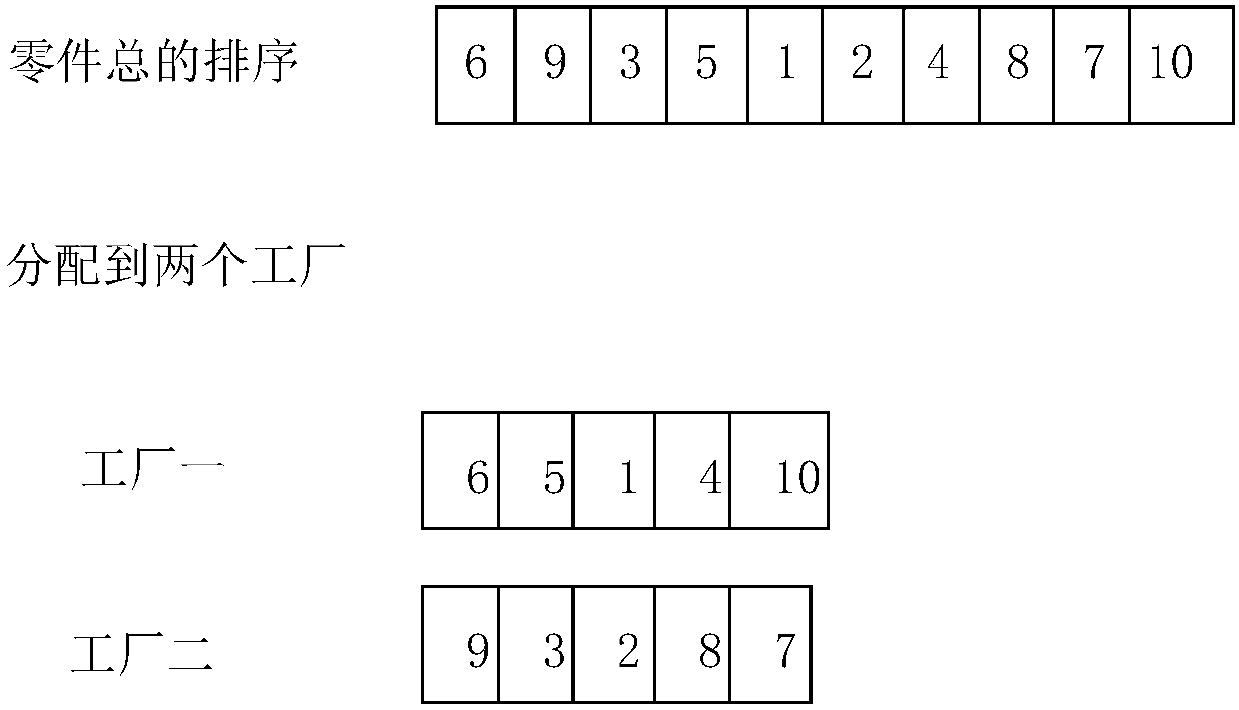

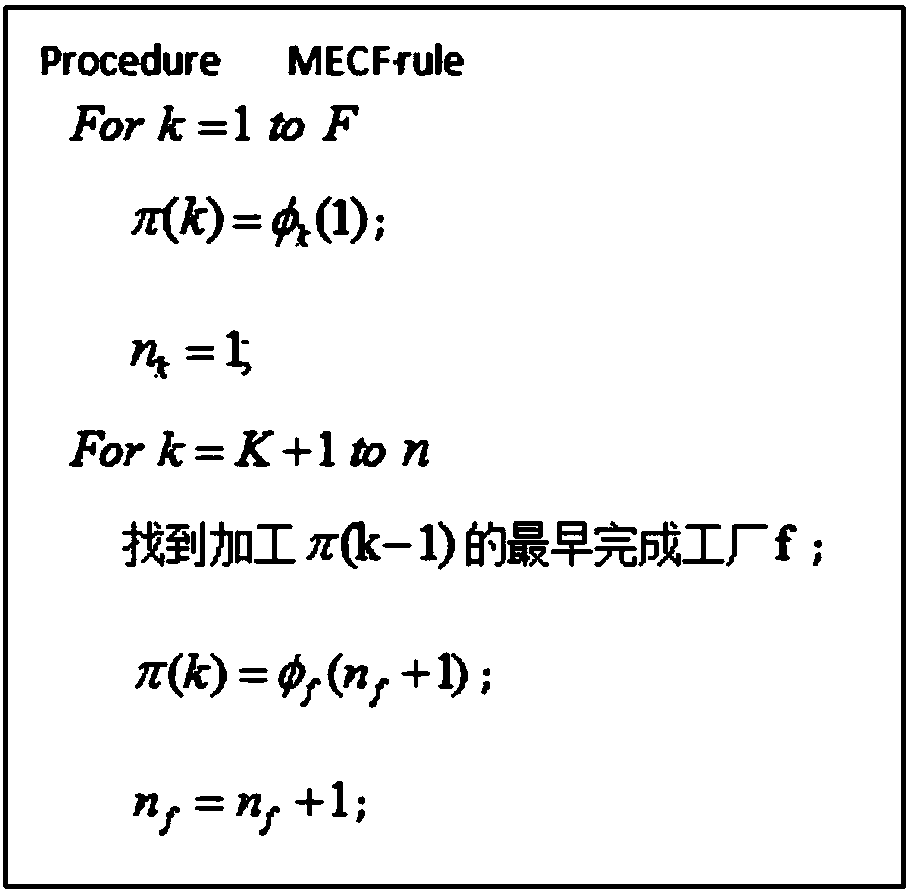

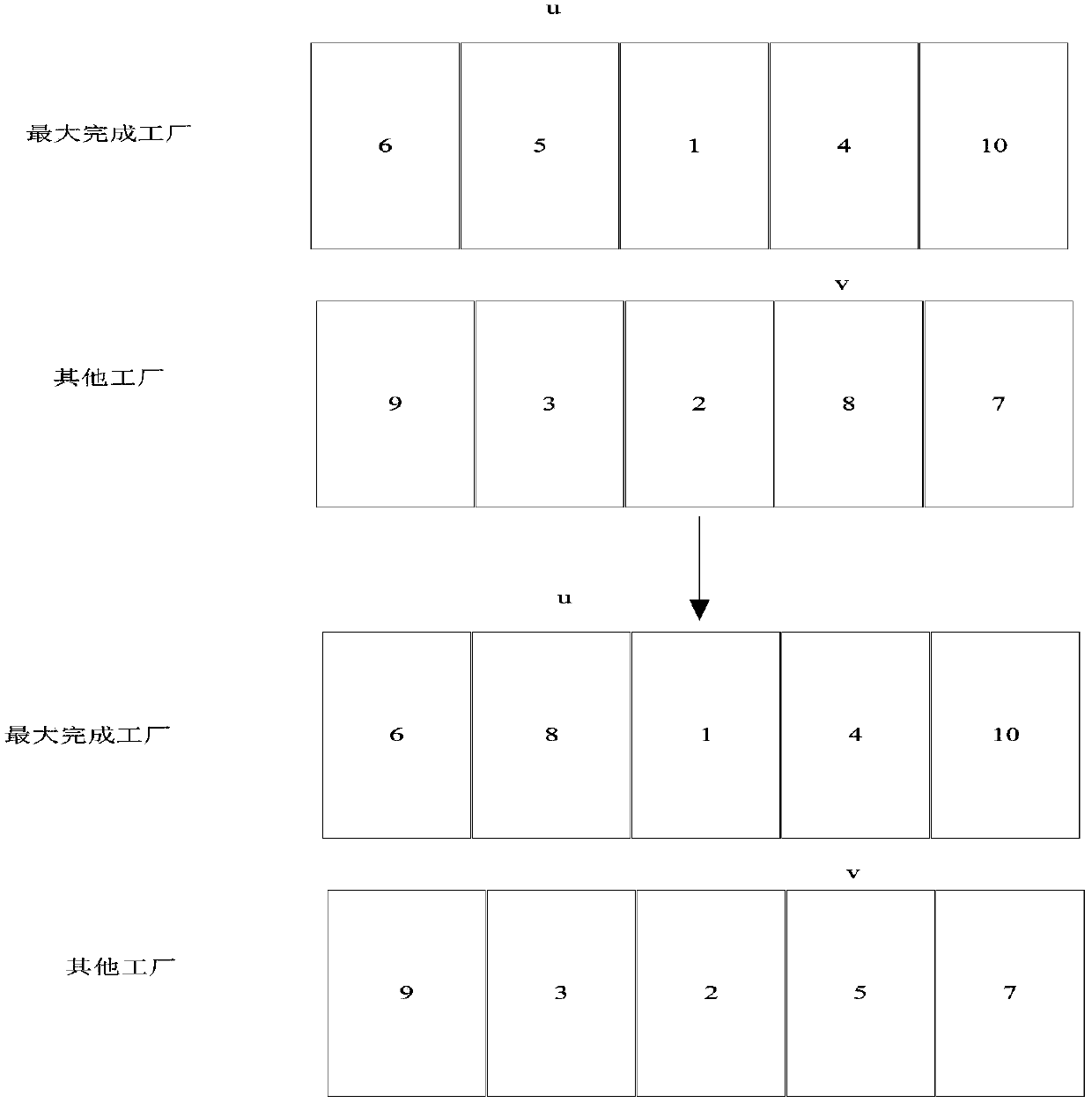

[0035] Embodiment 1: as Figure 1-5 As shown, an optimal scheduling method applied in the distributed manufacturing process of notebook parts, by determining the distributed replacement pipeline scheduling model with a limited buffer and the optimization target, and using the optimization method of the effective distribution estimation algorithm to optimize the target optimization; the scheduling model is established according to the processing completion time of each part on each machine, and the goal is to reduce the total completion time C max (π) is minimized:

[0036]

[0037]

[0038]

[0039] k=1,2,···F,i=1,2,···,n k ,j=1,2,...,m

[0040] Among them, F means that there are F isomorphic factories, k means a specific factory, n means the total number of notebook parts to be processed, n k Indicates the total number of notebook parts to be processed in factory k, i indicates the i-th position in the sorting of notebook parts to be processed in the factory, j in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com