Detection method and device of surface-mounted bonding pad

A detection method and pad technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as missed detection and low efficiency, and achieve the effect of improving work efficiency, shortening modification time, and avoiding poor welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

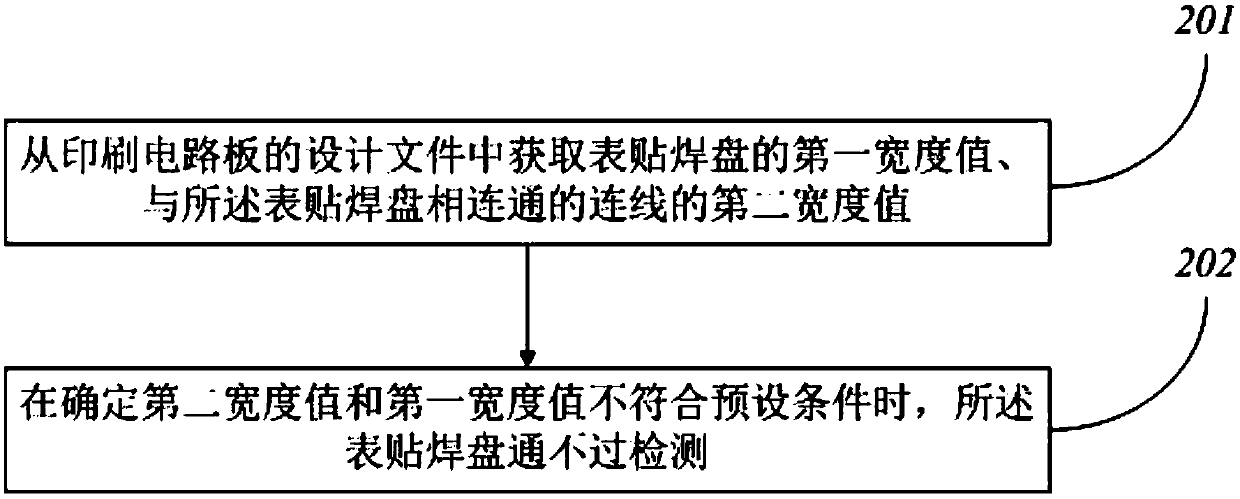

[0021] An embodiment of the present invention provides a detection method for surface mount pads, such as figure 2 shown, including the following steps:

[0022] Step 201: Obtain the first width value of the surface mount pad and the second width value of the connection line connected to the surface mount pad from the design file of the printed circuit board;

[0023] Here, the surface mount pads may be located on the top surface (ie, the TOP surface) or the bottom surface (ie, the Bottom surface). When the starting point or end point of the connection line is the same as the coordinates of the surface mount pad,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com