Ground transformer spraying and cooling system and method

A technology of spray cooling and transformer, which is applied in the direction of transformer/inductor cooling, spray device, spray discharge device, etc. It can solve the problems of water waste and failure to meet energy saving requirements, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

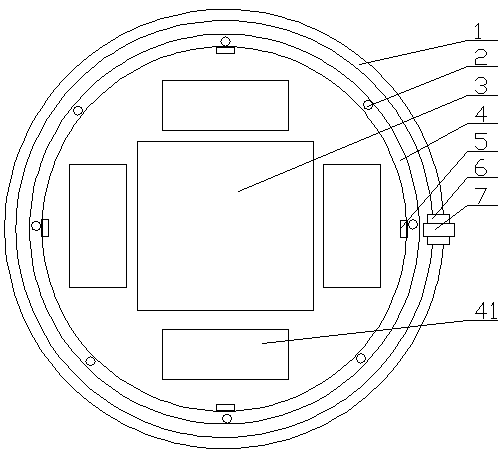

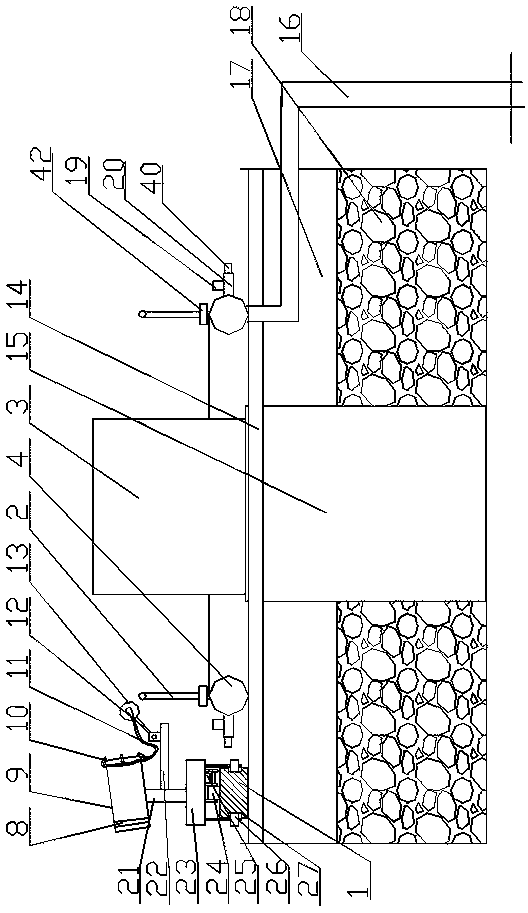

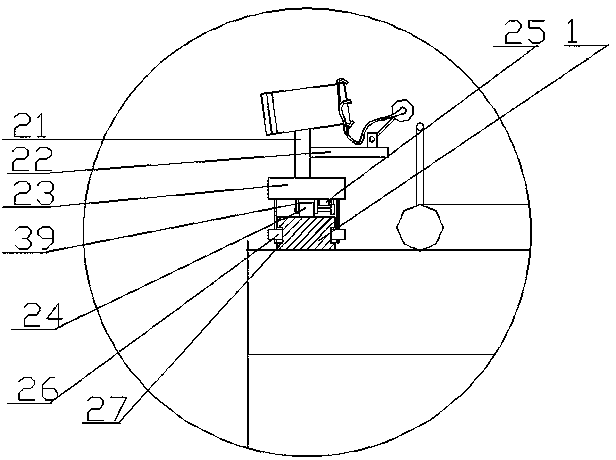

[0049] Embodiment 1. This embodiment provides an above-ground transformer spray cooling system, including a transformer 3, a base 15 supporting the transformer 3, and a frame platform 14 set on the ground around the transformer 3. The frame platform 14 A ring of pressure pipes 4 is arranged around the transformer 3, and the pressure pipes 4 communicate with the water supply mechanism. Corresponding to the pressure pipes 4, a running mechanism 6 is set on the frame platform 14, and a mist is set on the running mechanism 6. An atomization spraying mechanism 7, several L-shaped connecting pipes 2 are arranged vertically on the pressure pipe 4, the atomizing spraying mechanism 7 is matched with the connecting pipes 2, and the pressure pipe 4 corresponds to the Transformer 3 is provided with temperature monitoring mechanism 5, and described temperature monitoring mechanism 5 is connected with control mechanism, and described control mechanism is connected with described traveling me...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is:

[0058] The water supply mechanism includes a water tower 36, the water tower 36 communicates with the pressure pipeline 4 through a water pump 38 and a water supply pipeline 16, and a first electromagnetic valve 42 is arranged on the connecting pipeline 2, and the first electromagnetic valve 42 is connected to the pressure pipeline 4. Control mechanism signal connection.

[0059] The solar power generating mechanism 41 includes a solar panel arranged on the periphery of the transformer 3, and the environment cooling mechanism includes several water spray pipes 20 arranged outward on the pressure pipe 4, and the ends of the water spray pipes 20 are A spray head 40 is arranged on the upper part, and a second electromagnetic valve 19 is arranged on the water spray pipe 40, and the second electromagnetic valve 19 is connected with the control mechanism.

[0060] The pressure pipeline 4 is ring-shaped, and the ou...

Embodiment 3

[0074] This embodiment also provides a method for cooling the ground transformer by spraying, which includes the following steps:

[0075] S1. Monitor the surface temperature of the transformer through a non-contact infrared temperature sensor to reflect the temperature of each position of the transformer;

[0076] S2. When it is detected that the temperature of a certain place exceeds the threshold value, the traveling mechanism moves the atomizing spray mechanism to the connecting pipe corresponding to the position where the temperature of the transformer exceeds the threshold value;

[0077] S3. Connect the atomizing spray mechanism with the connecting pipe, and turn on the water pump of the water tower, so that the cooling water is sprayed out from the atomizing nozzle of the spray tube, and when spraying, it carries static electricity, and then flies through the wind force generated by the axial flow fan. to the transformer;

[0078] S4. When the atomized water droplets ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap