Anti-blocking operation control module for charging hole of spiral conveyor

A screw conveyor and control module technology, which is applied in the field of screw conveyors, can solve problems such as material accumulation at the feeding port, deformation of the feeding trough, and no beating at the feeding port is allowed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

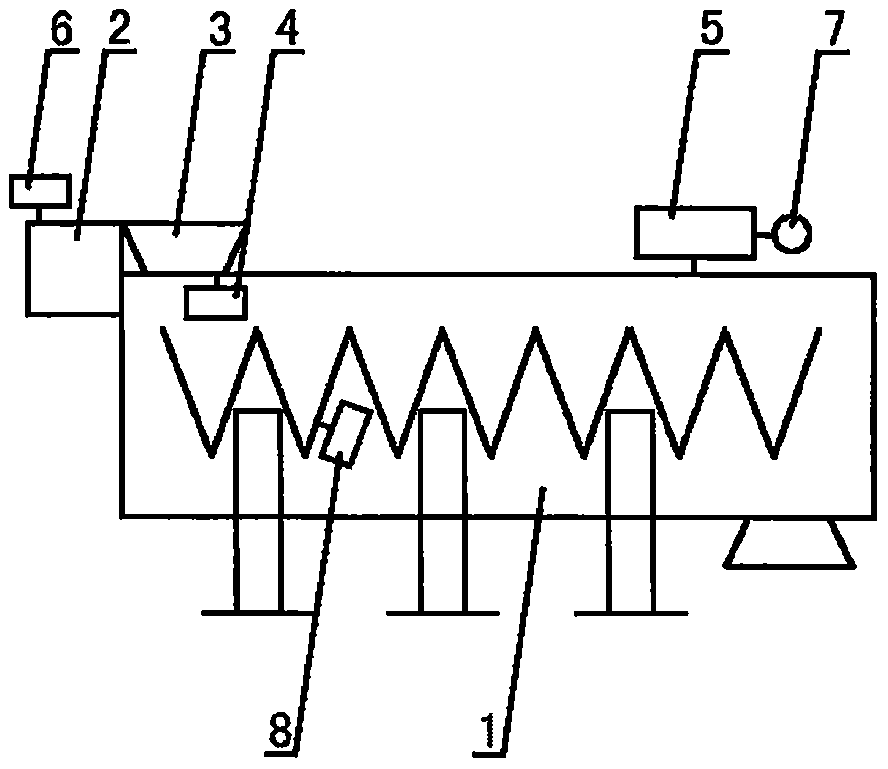

[0012] Embodiment: as shown in the accompanying drawing. The anti-blocking operation control module of the feeding port of the screw conveyor includes a body (1), on which a material storage module (2), a conveying module (3), a positioning module (4), and a management module (5) are arranged, During operation, the material storage module (2) is set on the upper part of the feeding tray of the machine body (1) for storage of materials, and the conveying module (3) can effectively control the materials in the material storage module (2) and complete them in an orderly manner For the conveying operation, the positioning module (4) is used for positioning the feed inlet of the machine body (1), and finally the management module (5) is used for processing.

[0013] The anti-blocking operation control module of the feeding port of the screw conveyor is provided with a material detection module (6) on the body (1) to detect the humidity and lump size of the material.

[0014] The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com