Multifunctional evaporated powder conveying equipment

A powder conveying and multi-functional technology, which is applied in the field of multi-functional evaporative powder conveying equipment, can solve the problems of conveyor belt scattering, the influence of the health status of workers in the factory environment, and the unsatisfactory powder flow control, and achieve a uniform powder conveying volume. , the structure is simple, the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

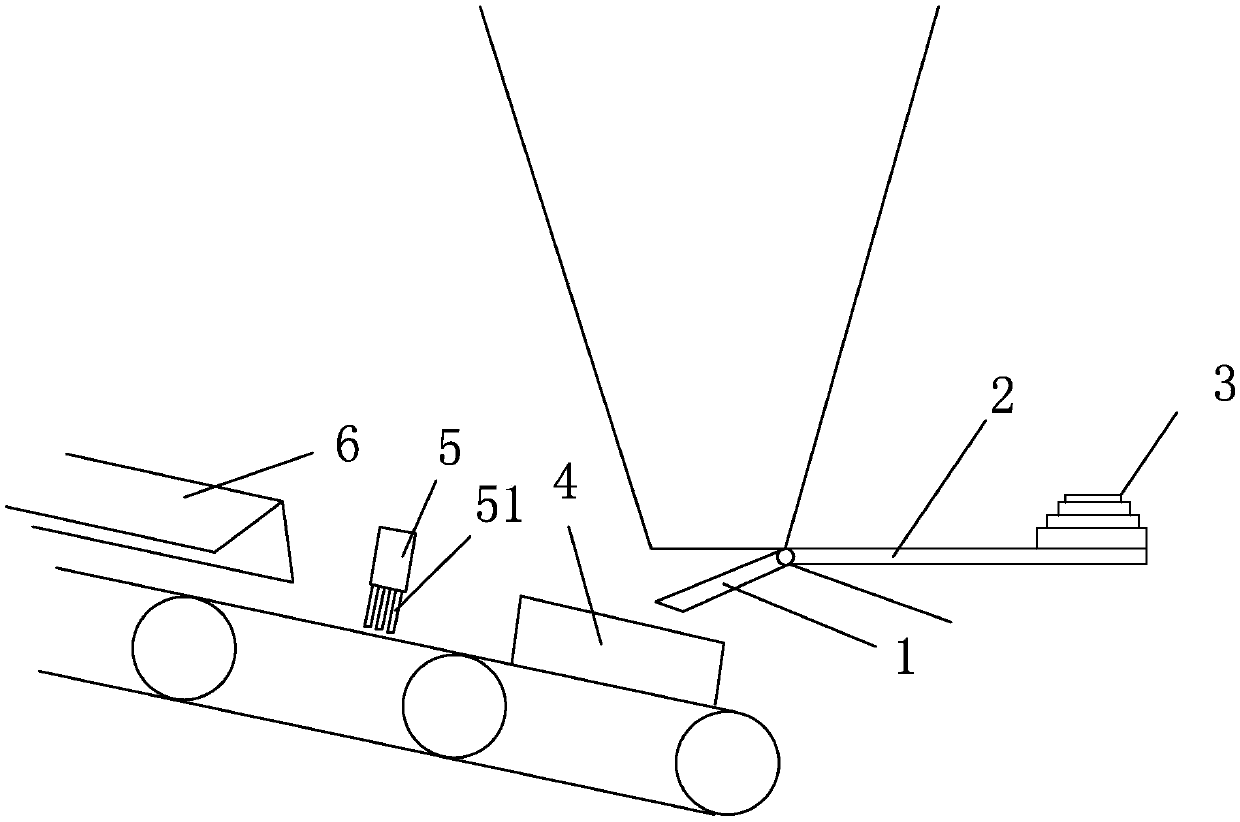

[0013] refer to figure 1 , a multi-functional evaporation conveying equipment, including a valve 1 arranged at the outlet of a hopper, a counterweight module for controlling the opening size of the valve 1, a dust-proof baffle 4 and an equalizing module 5 for initially evenly dividing powder, the valve 1 is set above the starting point of the conveyor belt. The counterweight module includes a support rod 2 and a counterweight 3. One end of the support rod 5 is connected to the movable fulcrum 11 of the valve 1. The counterweight 3 is mounted on the other end of the support rod 2. The plate 3 is arranged on both sides of the conveyor belt, the end of the dust-proof baffle 3 is in contact with the conveyor belt, and the other end is inclined outward. The equalizing module 5 includes three equalizing parts 51, and the equalizing parts 51 are cylindrical iron parts. The width of the powder material on the conveyor belt is divided into four equal widths, and the equalizing part 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com